Method and system for calculating depth of rotating area of tuyere of blast furnace

A convolution area and depth technology, applied in the computer field, can solve problems such as low efficiency and complex implementation, and achieve the effect of simplifying complexity, reducing computing time, and improving computing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

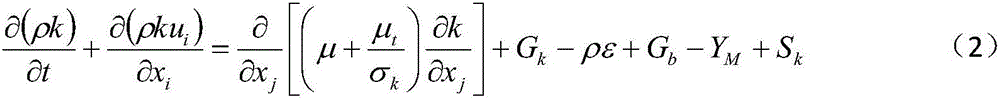

Method used

Image

Examples

Embodiment 1

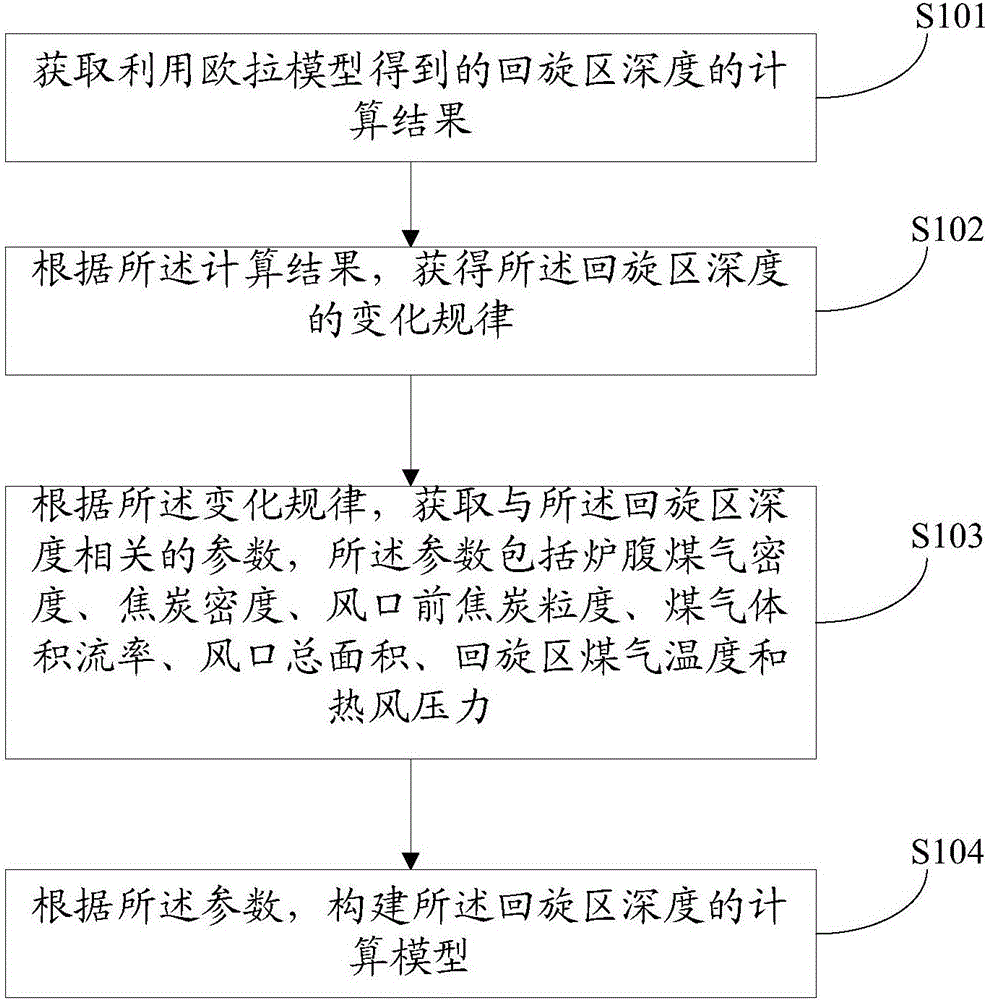

[0036] This embodiment provides a method for calculating the depth of the blast furnace tuyeres swirl zone, please refer to figure 1 , the method includes:

[0037] Step S101, obtaining the calculation result of the depth of the convolution area obtained by using the Euler model;

[0038] Step S102, according to the calculation result, obtain the change law of the depth of the convolution zone;

[0039] Step S103, according to the change rule, obtain parameters related to the depth of the swing zone, the parameters include bosh gas density, coke density, coke particle size before the tuyere, gas volume flow rate, total area of the tuyere, gas temperature in the swing zone and hot air pressure;

[0040] Step S104, according to the parameters, construct the calculation model of the depth of the maneuver zone, the calculation model is: Among them, D R is the depth of the turning zone, ρ o is the bosh gas density, ρ s is the coke density, D P is the coke particle size be...

Embodiment 2

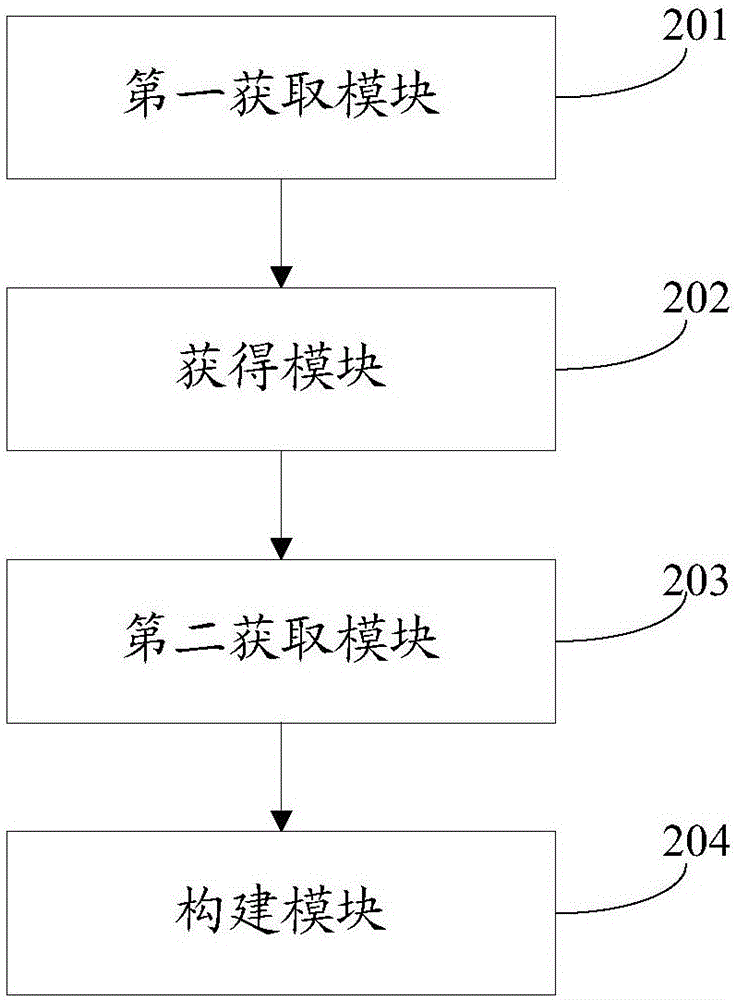

[0076] This embodiment provides a system for calculating the depth of the blast furnace tuyere swirl zone, please refer to figure 2 , the system includes:

[0077] The first obtaining module 201 is used to obtain the calculation result of the depth of the convolution area obtained by using the Euler model;

[0078] An obtaining module 202, configured to obtain the change law of the depth of the convolution region according to the calculation result;

[0079] The second acquisition module 203 is used to acquire parameters related to the depth of the swing zone according to the variation law, the parameters include bosh gas density, coke density, coke particle size before the tuyere, gas volume flow rate, and the total area of the tuyere , gas temperature and hot air pressure in the roundabout area;

[0080] A construction module 204, configured to construct a calculation model of the depth of the maneuver zone according to the parameters, the calculation model being:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com