Assembled blind cable ditch

A cable trench and assembly technology, applied in cable installation, cable installation in underground pipelines, etc., can solve problems such as inclination, subsidence, deformation, water accumulation, etc., and achieve good durability, high overall strength, and extremely fast construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

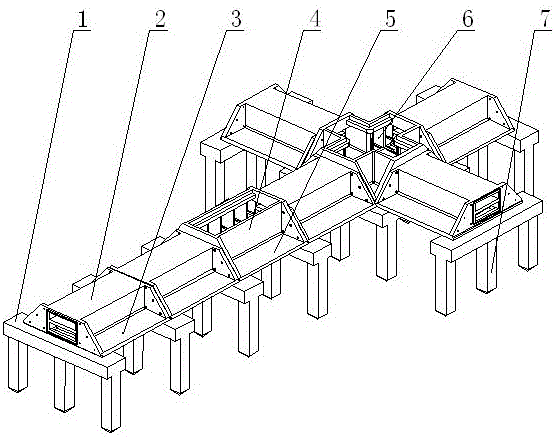

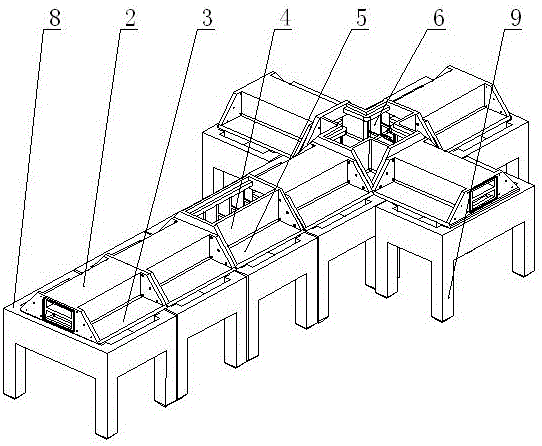

[0028] As shown in the figure, the prefabricated concealed cable trench includes underground infrastructure and cable trench assembly, and the cable trench assembly is set above the underground infrastructure. In the cable trench assembly, seals are embedded between the hidden cable trench 2 and the hidden cable trench 2, between the hidden cable trench 2 and the open cable trench 4, and between the hidden cable trench 2 and the intercommunicating cable trench 6. After the screws are fixed, they are connected into one body; the cable trench 4 is set up in sections in the cable trench assembly, which is convenient for cable laying and maintenance.

[0029] The said concealed cable trench 2, the prefabricated concealed cable trench 2 is a business type, and it is equipped with a cable bracket for supporting the cables; it is equipped with an anti-settling, inclined extension edge A 3, and an anti-settling, inclined extension edge A 3 The two ends of the triangle are connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com