Welded framework follow fixture

A traveling fixture and skeleton technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low degree of automation, complex operation procedures, low production efficiency, etc., and achieve high degree of automation, convenient manufacturing, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

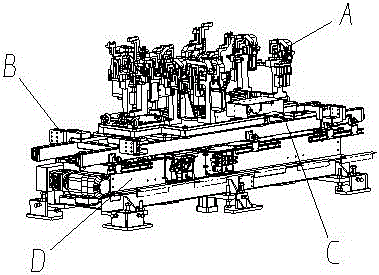

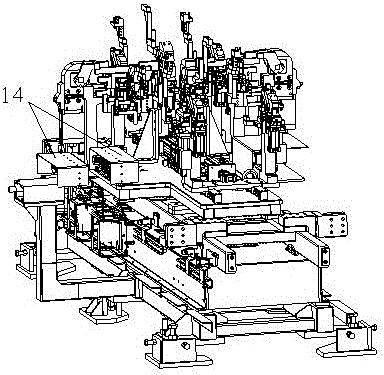

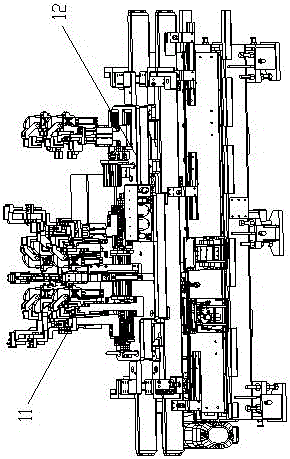

[0019] refer to Figure 1-8 As shown, a welding skeleton fixture includes a welding skeleton fixture A, a sled B, and a conveying roller bed D. The welding skeleton fixture A includes a positioning and clamping unit 11, a BASE board 12, and an air pressure detection gauge (not shown) , the positioning and clamping unit 11 is a European standard cylinder with a four-bar linkage locking function, the welding skeleton fixture A and the skid B are connected by pins and bolts, and the welding skeleton fixture A, BASE plate 12 and the conveying roller bed D are mounted on There is an electrical connection quick-plug device C, and the electrical connection quick-plug device C includes an accompanying base 8 and a fixed base 9, and the accompanying base 8 is equipped with an electrical signal plug female 1, a trachea plug female 3 and a guide plug female 5. The fixed base 9 is installed with the electrical signal plug male 2 docked with the electrical signal plug female 1, the trachea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com