Cleaning device for glass cutting

A cleaning device, glass cutting technology, applied in the direction of liquid cleaning method, dry gas arrangement, cleaning method and utensils, etc., can solve the problems of operator damage, hand scratches, etc., to improve quality, avoid direct contact, improve The effect of collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

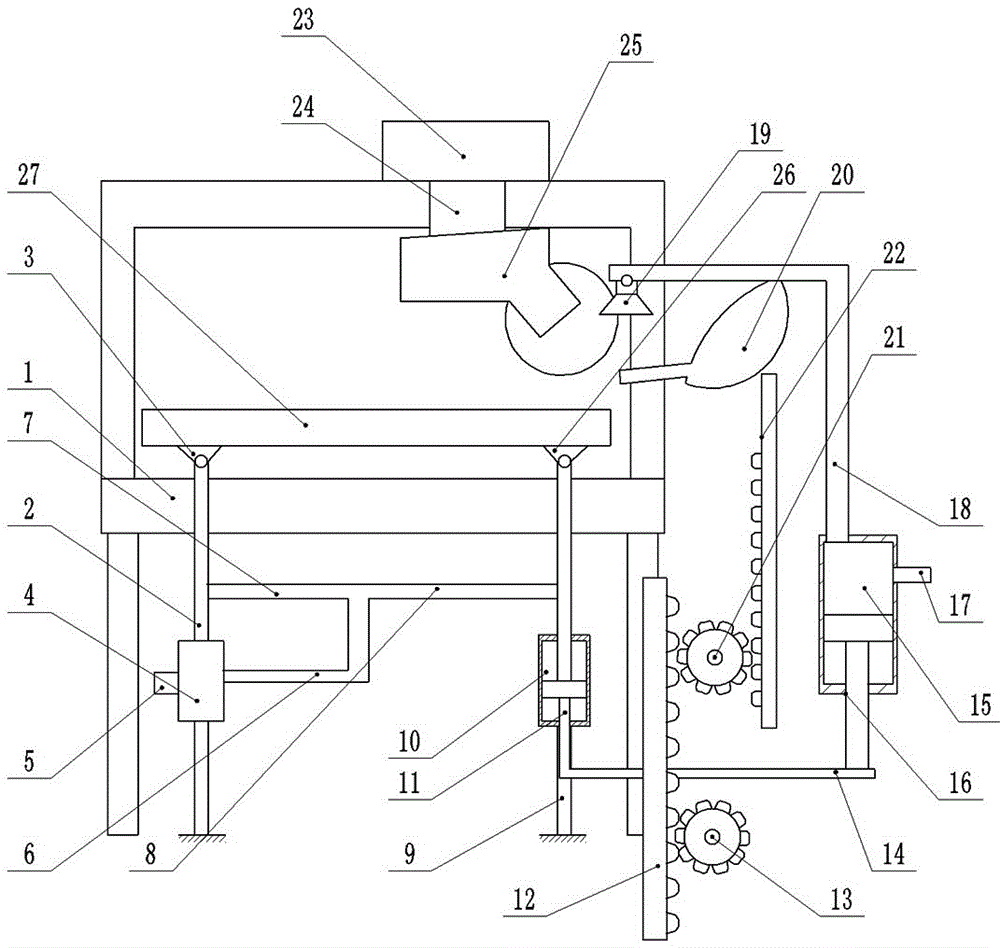

[0024] Basic as attached figure 1 Shown: a cleaning device for glass cutting, including a workbench 1, two through holes are respectively opened on the workbench 1, and first support rods 2 are slidingly fitted in the through holes, the first support rods 2 are hollow, and the first support rods 2 are hollow. There is a first suction cup 3 on the top ball hinge of a support rod 2, and a first ventilation hole is opened at the bottom of the first suction cup 3. A blowing box 4 is installed on the lower part of the first support rod 2, and a ventilation pipe 5 is integrally formed on the left side of the blowing box 4. The right side of the blowing box 4 is integrally formed with an air guide tube 6, and the port of the air guide tube 6 is integrally formed with a first sub-pipe 7 and a second sub-pipe 8, and the first sub-pipe 7 communicates with the first support rod 2.

[0025] A cylinder 10 is installed on the top of the second support rod 9, and a first piston 11 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com