Spherical coordinate frame 3D printer with rotary hot bed

A 3D printer and spherical coordinate system technology, applied in the field of 3D printing, can solve the problems of inconvenient leveling and poor printing effect, and achieve the effect of reasonable structural design and high printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

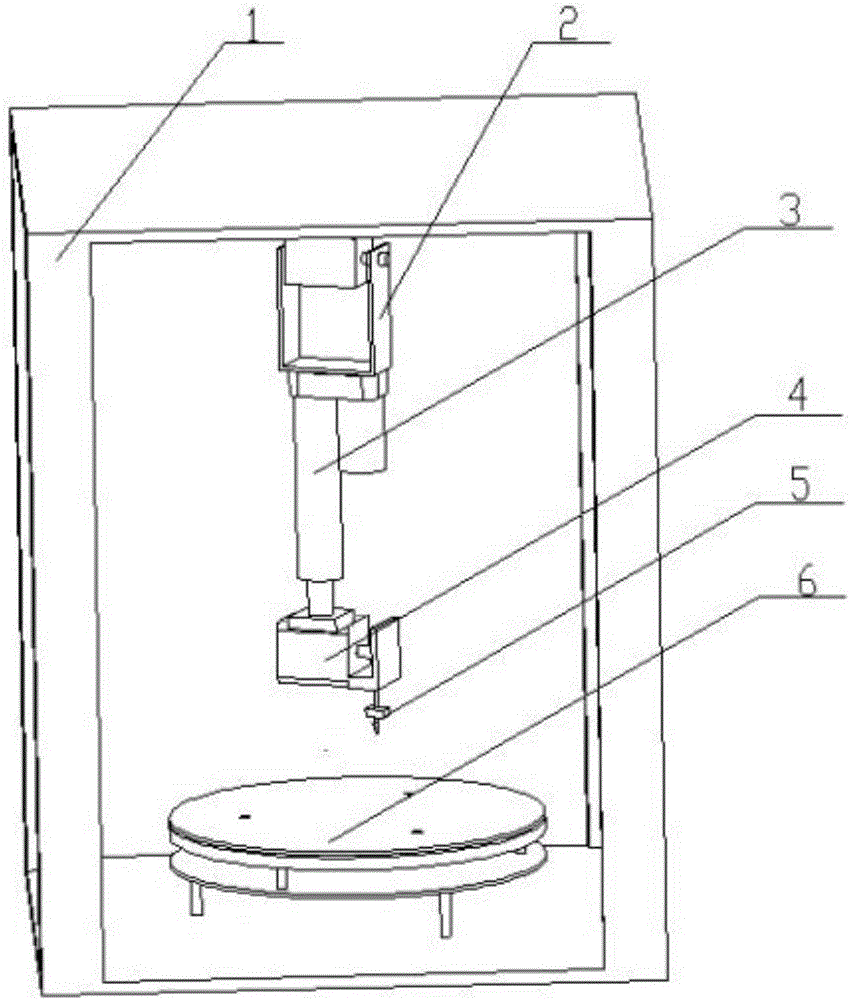

[0011] Such as figure 1 As shown: the X-Y plane rotating heating bed 6 is fixed on the bottom of the outer frame 1 by screws, the X-Y plane rotating heating bed 6 controls the printing point of the filament nozzle 5 to rotate in the X-Y plane, and the X-Y plane rotating heating bed 6 and the filament nozzle 5 are connected The positions are corresponding; the wire guide motor 4 and the wire outlet nozzle 5 are fixed on the R-direction telescopic rod 3 through screws and connectors, and the wire guide motor 4 controls the resin wire output of the wire outlet nozzle 5; the R-direction telescopic rod 3 is fixed by screws On the Y-Z plane swing arm 2, the telescopic rod 3 in the R direction controls the movement of the silk nozzle 5 in the R direction, and the Y-Z plane swing arm 2 is fixed on the top of the outer frame 1 by screws, and the Y-Z plane swing arm 2 controls the silk nozzle 5 in the Rotation of the Y-Z plane.

[0012] The outer frame 1 is a machined sheet metal frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com