Automatic carriage body scrolling-type closed system

A closed system and box technology, applied to motor vehicles, vehicles used for freight, load coverage, etc., can solve problems such as welding errors, movement jams, prone to bumping, deformation, etc., to achieve convenient processing and strong applicability , install flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

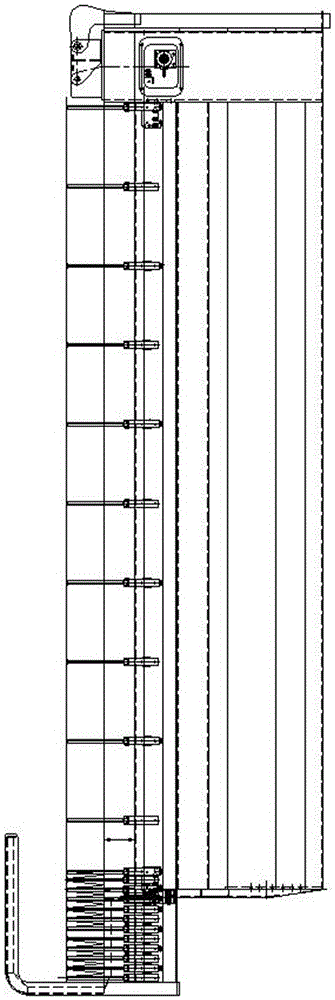

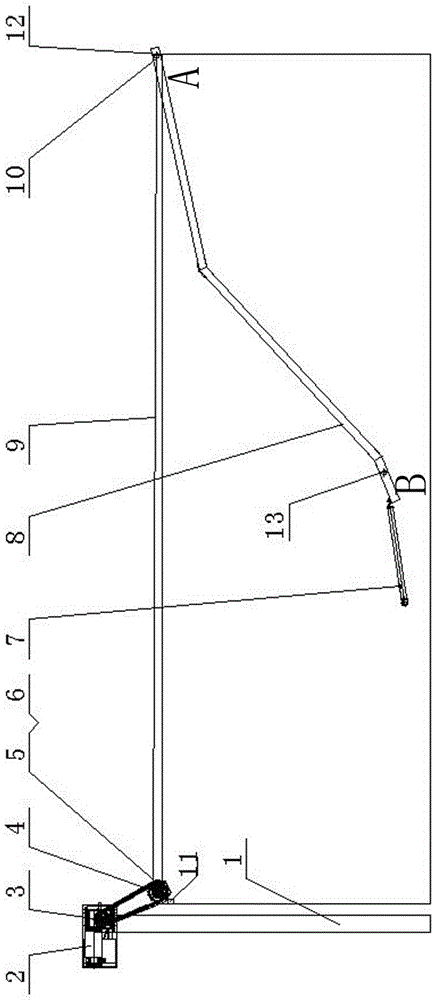

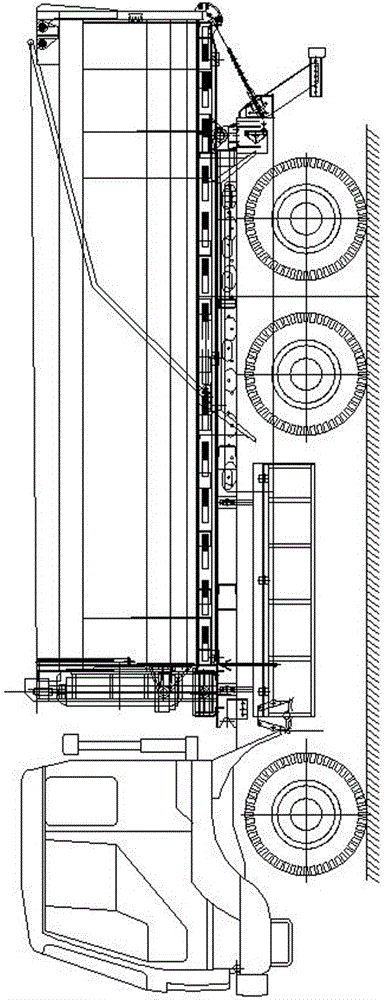

[0028] The present invention as Figure 2-7 shown.

[0029] A car body rolling type automatic closed system, including a car body 14, the front end of the car body 14 is provided with an erection mechanism 1, wherein the erection mechanism 1 is provided with a motor or hydraulic motor 2; There is a rotating shaft 4, on which a tarpaulin 9 is wound, and the other end of the tarpaulin 9 extends to the tail end of the dump truck body 14 and is provided with a tail end shaft 10;

[0030] The two sides of the car body 14 are also provided with pull rods 8, wherein the A end of the pull rod 8 is hinged to the tail end shaft 10, and the B end of the pull rod 8 is hinged on the two sides of the car body 14 through the rotation fulcrum 13;

[0031] The two ends of the rotating shaft 4 are provided with transmission gears 5, and the drive shaft 3 of the motor or hydraulic motor 2 is connected with the transmission gears 5 at the two ends of the rotating shaft 4 through a chain 6.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com