An anti-winding crawler drive wheel with track blocks

A crawler drive, anti-winding technology, used in crawler vehicles, motor vehicles, transportation and packaging, etc., can solve problems such as damage to the crawler structure, hindered driving, and affecting work tasks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

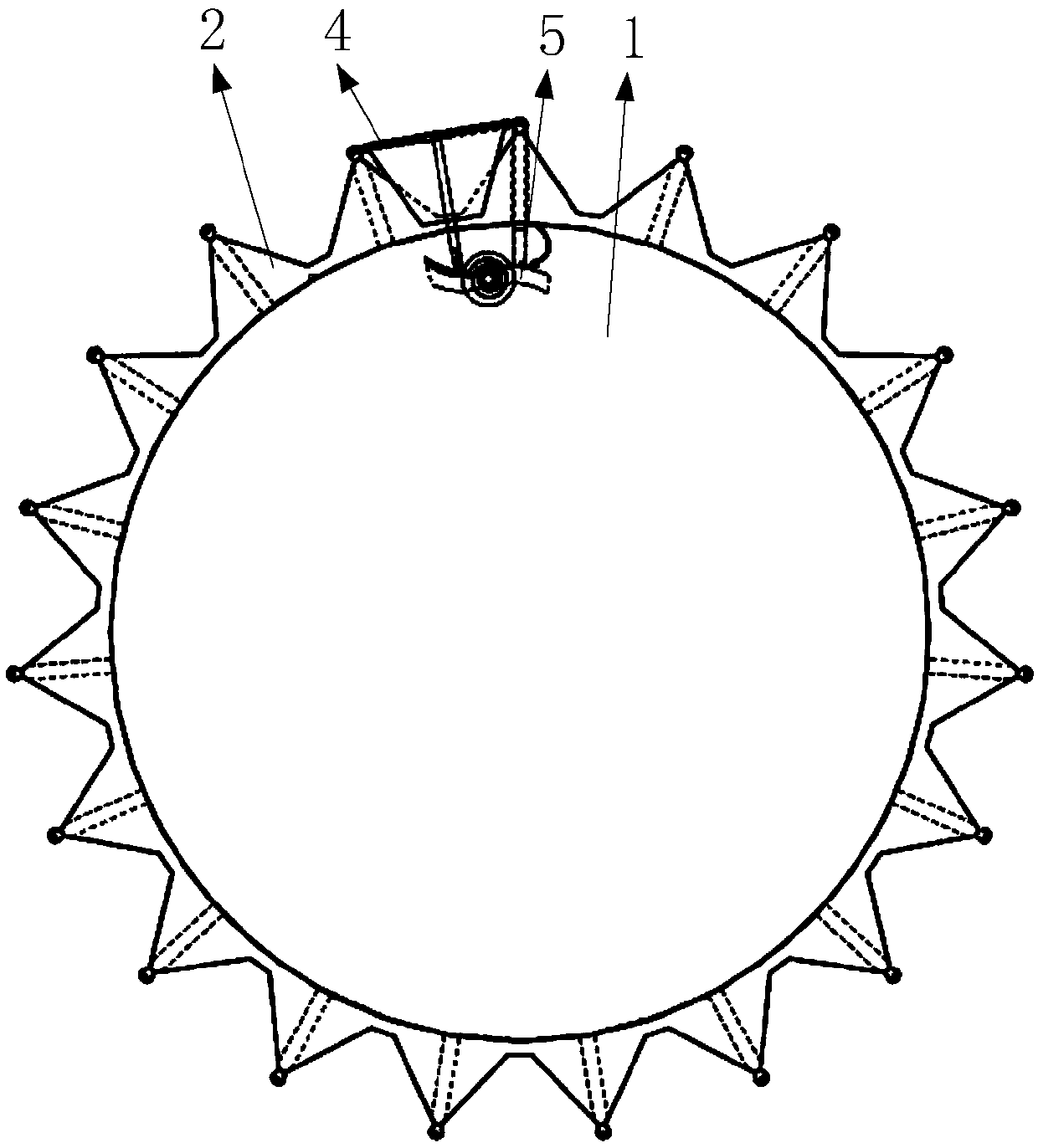

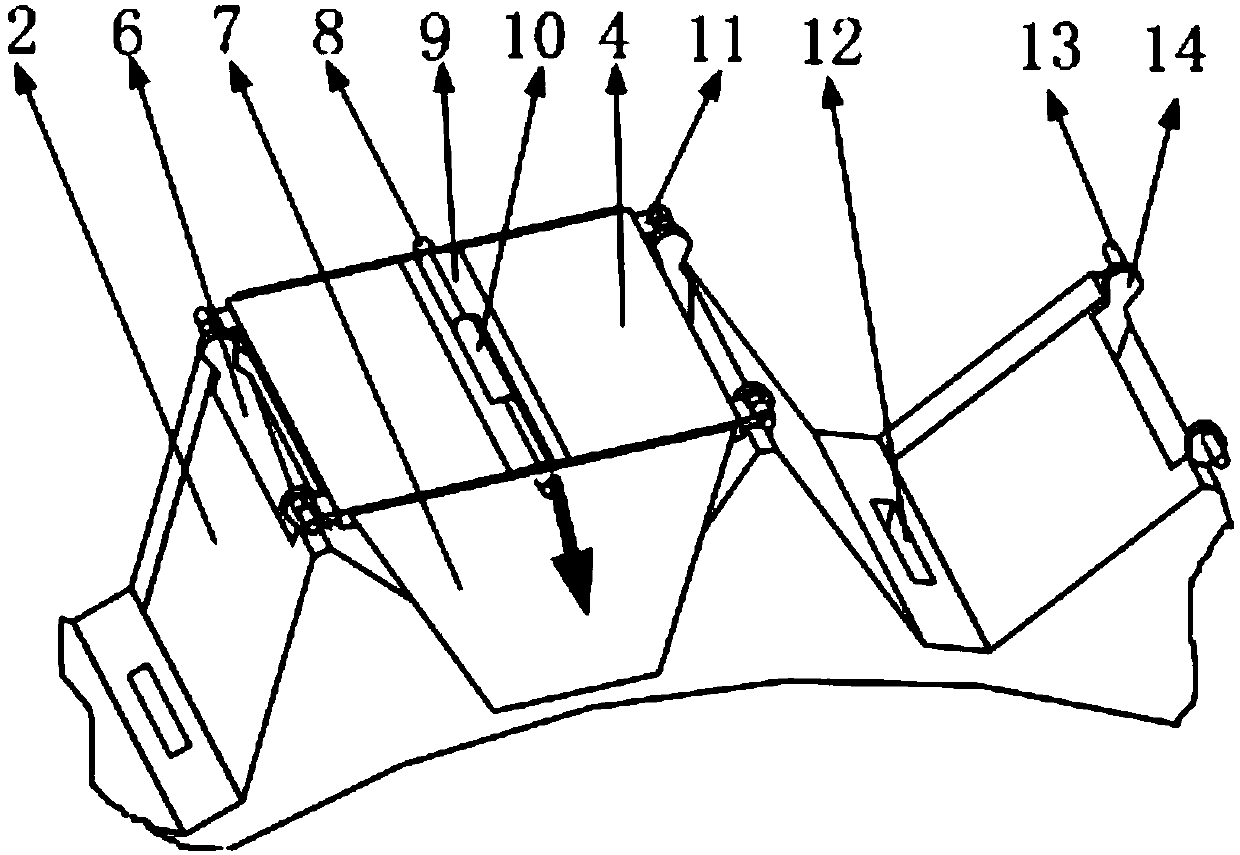

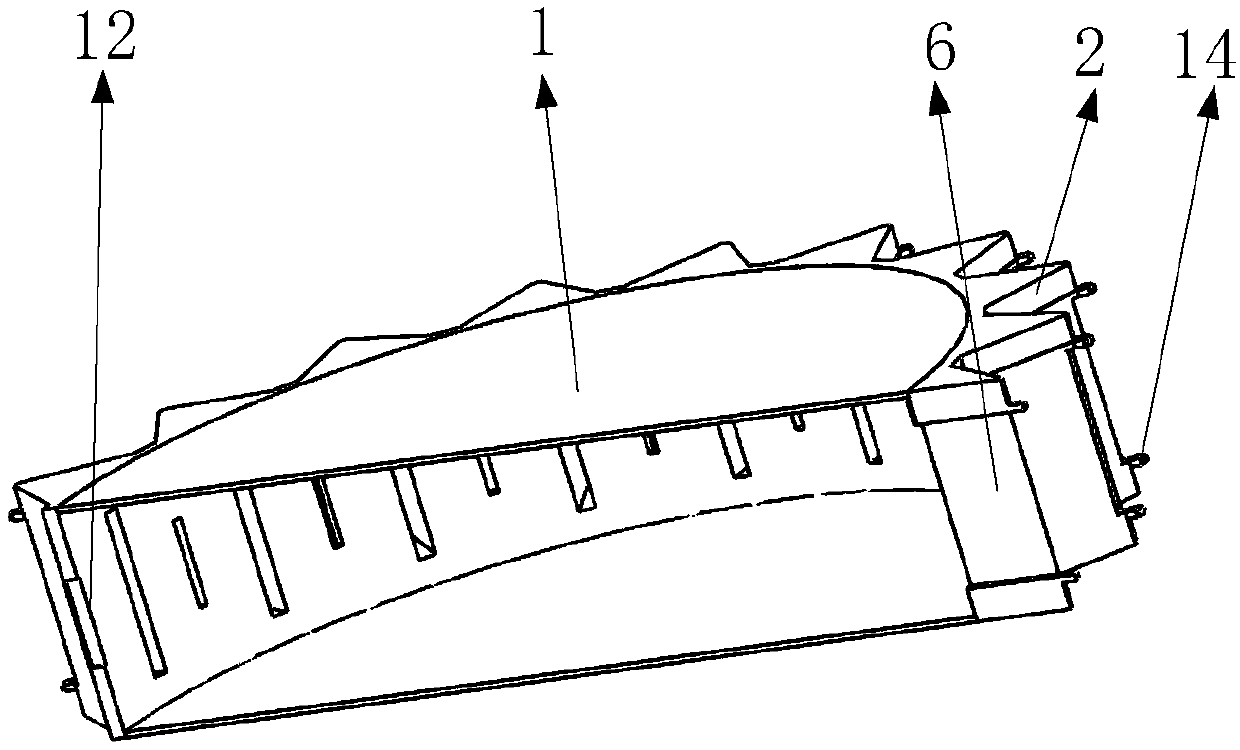

[0028] Such as figure 1 , 2 , as shown in 12, it includes side plates, shells, retaining sleeves, adjustment mechanisms, card channels, side baffles, jacking shafts, top shaft side swivel sleeves, top shaft transfer sleeves, anti-collision blocks, pressure applying channels, and end shafts , end lugs, anti-collision block lugs, retainer sleeve inner groove, retainer inner plate, crawler chain, chain slope, chain top mouth, chain top surface, among which such as figure 1 , 3 As shown in the figure, only a pair of structures at two adjacent sharp corners are shown in the figure, and this structure is distributed between all sharp corners and adjacent sharp corners; the shell is hollow in the middle, and how many A sharp corner; side panels are installed on both sides of the shell, such as figure 2 As shown, an end shaft is installed on both sides of the top of the sharp corner through an end lug, the groove between the sharp corner and the adjacent sharp corner has a pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com