Positioning technology of braided type capacitor

A positioning technology and braided technology, which is applied in the field of improvement of electronic components, can solve the problems of small stress and uneven product height, achieve the effects of increasing the stress area, reducing repair costs, and changing the direction of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

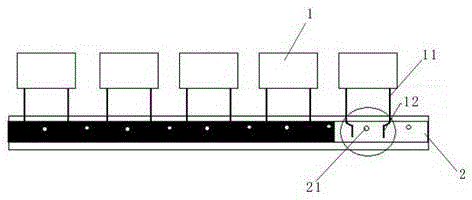

[0010] Such as figure 1 The present invention shown is a positioning technology of a braided capacitor, including a capacitor 1 and a braid 2, the bottom of the capacitor 1 is provided with two pins 11, and the lower part of the two pins 11 is provided with an inverted L-shaped curved head 12, the braid 2 is divided into two front and back, the middle of the braid 2 is provided with a plurality of positioning holes 21 with equal distances, and the lower parts of the two pins 11 are inserted into the two front and rear braids 2, and the central axis of the capacitor 1 is on the same line as the positioning hole 21.

[0011] The inner side of the braid 2 is provided with elastic glue, and the elastic glue material is composed of the following material ratios:

[0012] 26 parts of polyester, 7 parts of polyester amide, 3 parts of rosin, 8 parts of paraffin, 3 parts of pearl cotton, 2 parts of acrylic acid, 35 parts of acrylic acid, 18 parts of tetrabutylammonium bromide.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com