Automatic speed-reduction rewinder

A rewinding machine, automatic technology, applied in the field of toilet paper production, can solve the problems of speeding up the roll paper, toilet paper cracking, paper breaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

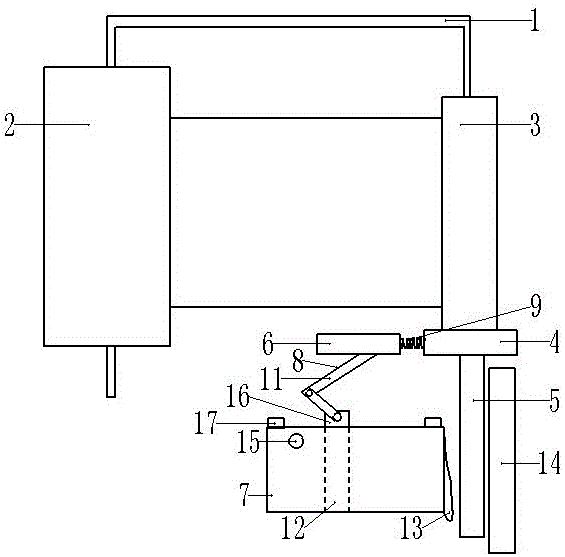

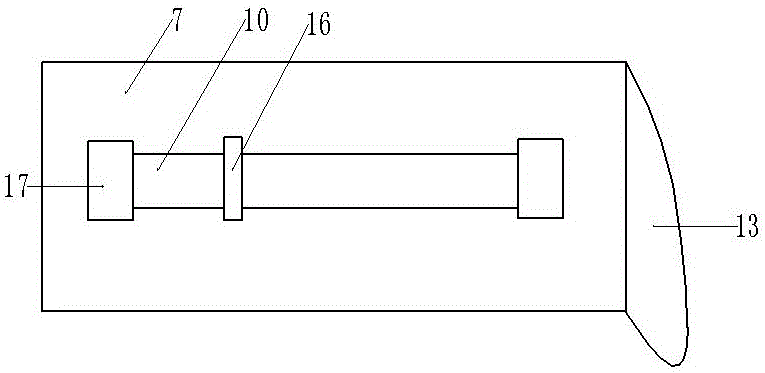

[0015] The reference signs in the accompanying drawings of the specification include: frame 1, large roll paper roll 2, rewind paper roll 3, turntable 4, turning rod 5, push block 6, gas filling box 7, L-shaped connecting rod 8, spring 9 , chute 10, pole 11, piston 12, elastic air bag 13, baffle plate 14, vent hole 15, thin handle 16, limit block 17.

[0016] The embodiment is basically as figure 1 and figure 2 Shown: automatic speed-reducing rewinding machine, including frame 1, large roll paper roll 2, rewind paper roll 3 and speed reduction mechanism, large roll paper roll 2 is connected to the left end of frame 1 in rotation, and rewind paper roll 3 Rotationally connected to the right end of the frame 1, the lower end of the rewinding paper roller 3 is welded with a turntable 4, and the lower end of the turntable 4 is welded with a rotating rod 5, and the right sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com