Retractable loose winding drum for testing optical cable

A disc and loose winding technology, which is applied in the direction of optical instrument testing, machine/structural component testing, measuring devices, etc., can solve the problems of uneconomical, deformation damage, manpower and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

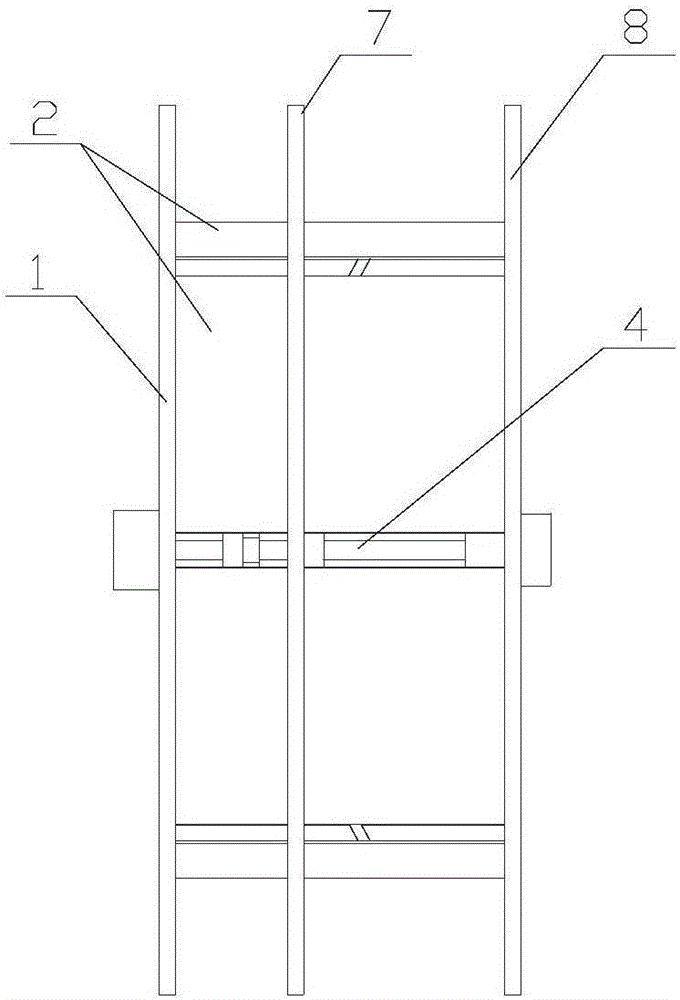

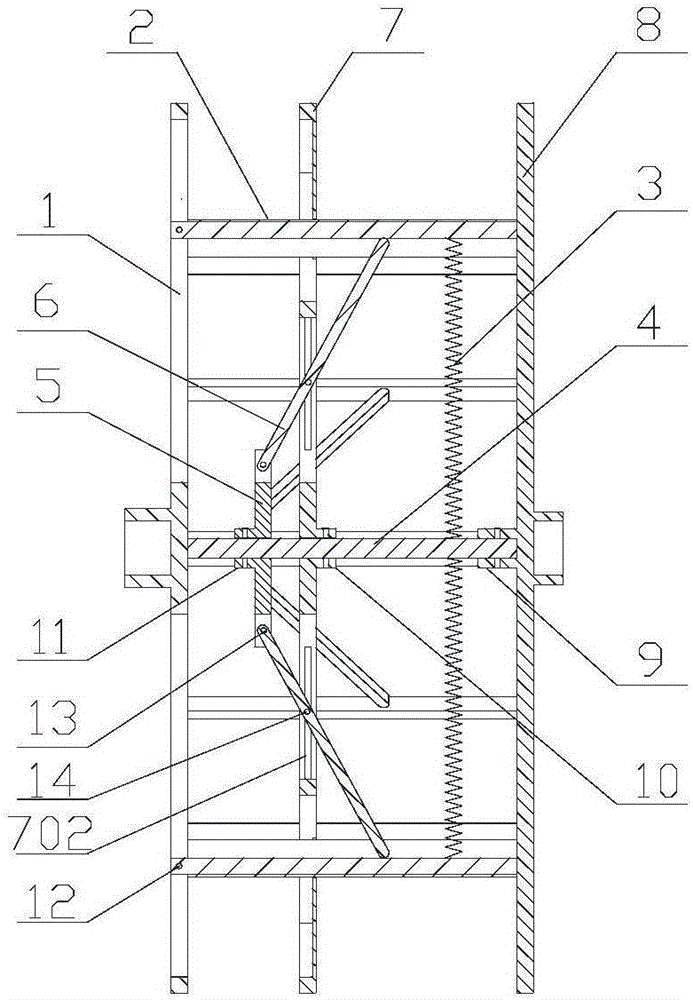

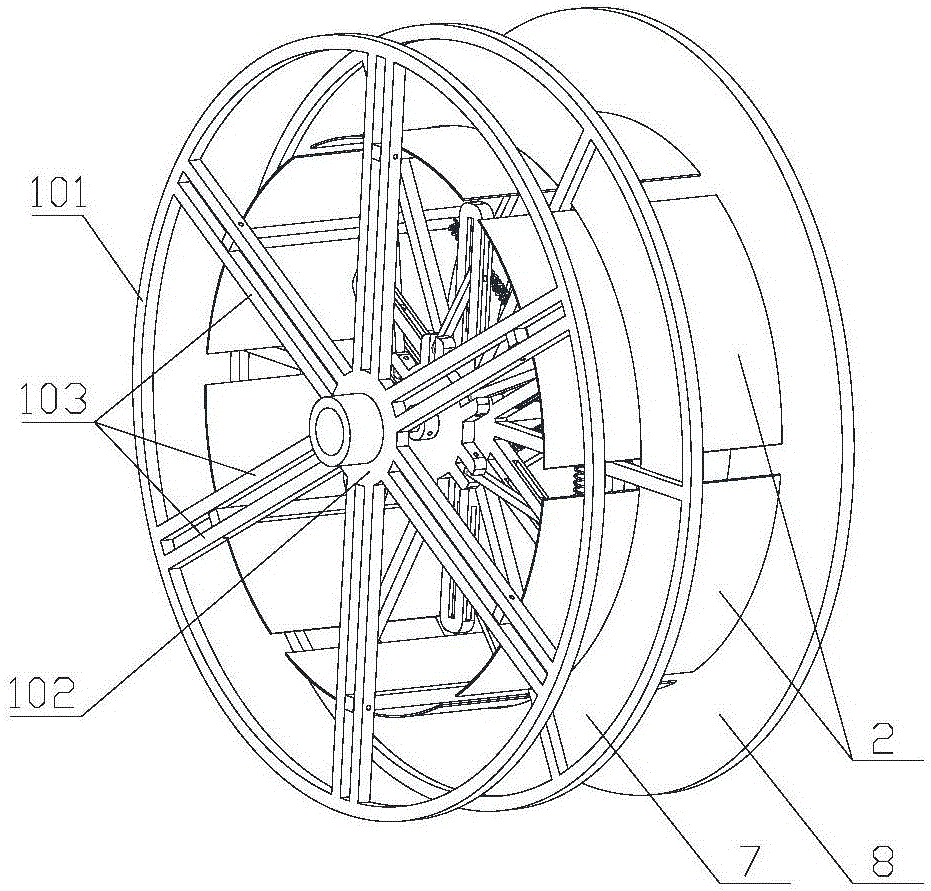

[0037] figure 1 , figure 2 , image 3 It shows a shrinkable loose winding reel for optical cable testing, including a first fixed side plate 1, a second fixed side plate 8 and a central cylinder, the central cylinder is composed of six central cylinder plates 2 with the same circumferential width composition (such as Figure 8 shown), one end of the central tube plate 2 is pivotally connected to the first fixed side plate 1 through the tube plate positioning shaft 12, and the other end of the central tube plate 2 is matched with the second fixed side plate 8 Bonding; there is an effective distance between two adjacent central tube plates 2 so that the central tube plate 2 can be turned inward at an effective angle at the same time (in use, so that the optical cable on the reel can be in the loose winding required by the test. state), such as Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com