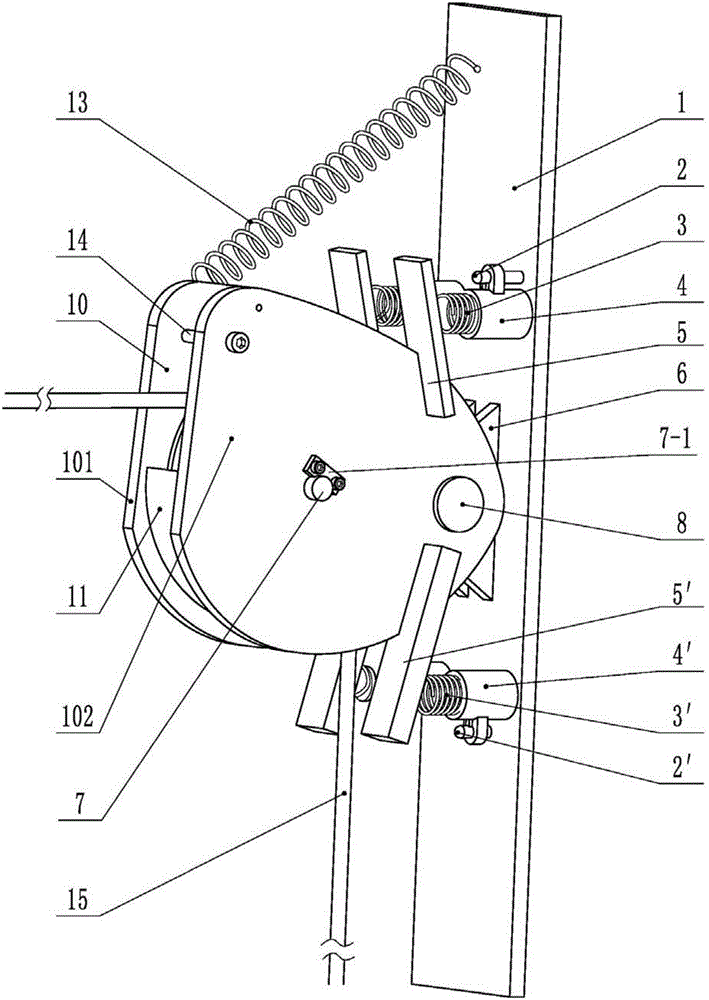

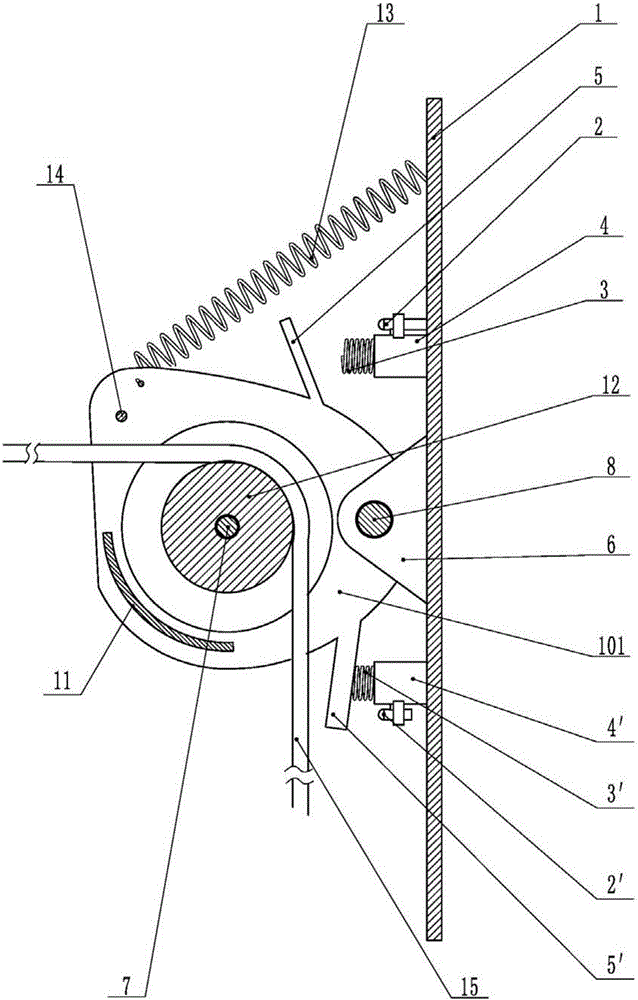

Bidirectional limiting device swinging based on tension of steel wire rope

A two-way limit and wire rope technology, which is applied in the field of limit devices and wire rope guides, can solve the problems of inability to achieve accurate limit and accurate monitoring of wire rope tasks, and achieve the effects of convenient operation, increased life, and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

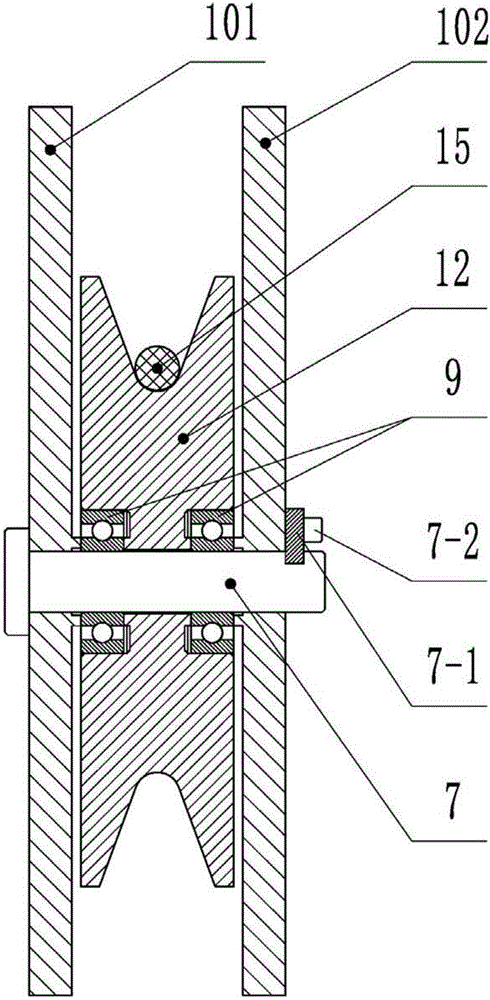

[0012] Such as Figure 4 As shown, the steel wire rope 15 set in the "V" groove of the guide wheel 12 is in a loose state. At this time, the guide wheel frame 10 will rotate upward around the support pin shaft 8 under the action of the tension spring 13, but it is limited by the limit bolt 14. The blocking of the groove will not occur, and at the same time, the upper limit pressure plate 5 is in conflict with the buffer spring 3, which plays a buffer role; Figure 5 It is shown that the steel wire rope 15 is in a tensioned state. At this time, the guide wheel frame 10 will rotate downward around the support pin shaft 8, and the tension will be slowed down by the action of the tension spring 13, so as to overcome the excessive friction loss. At the same time, The lower limit pressure plate 5' is in conflict with the lower buffer spring 3' to play a buffering role.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com