Polyacrylamide diluting device for sewage treatment

A polyacrylamide and sewage treatment technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problem of not being able to store for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

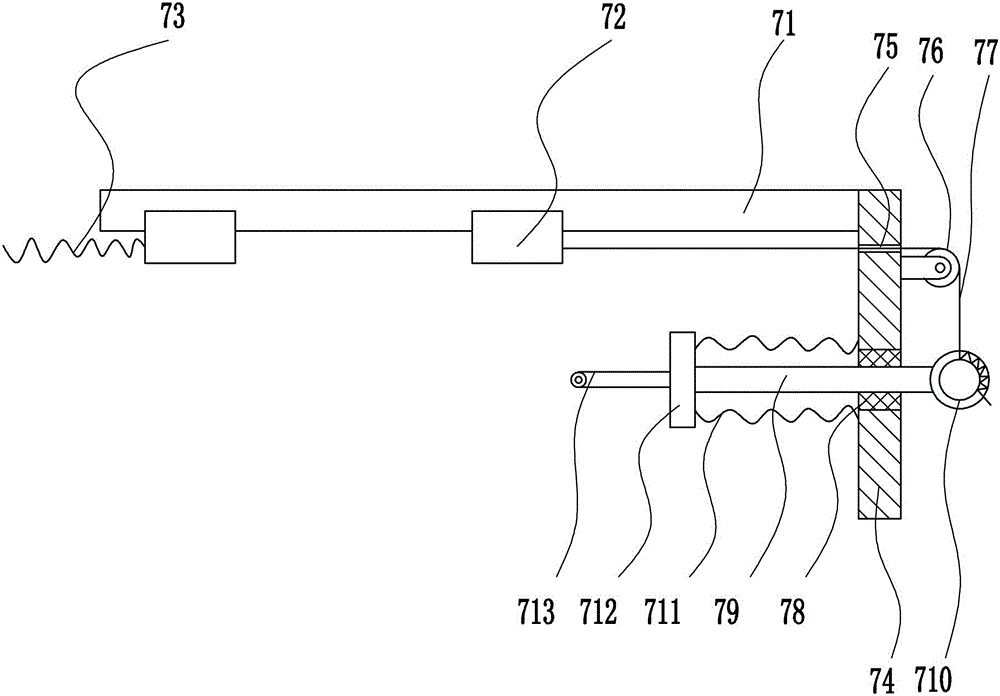

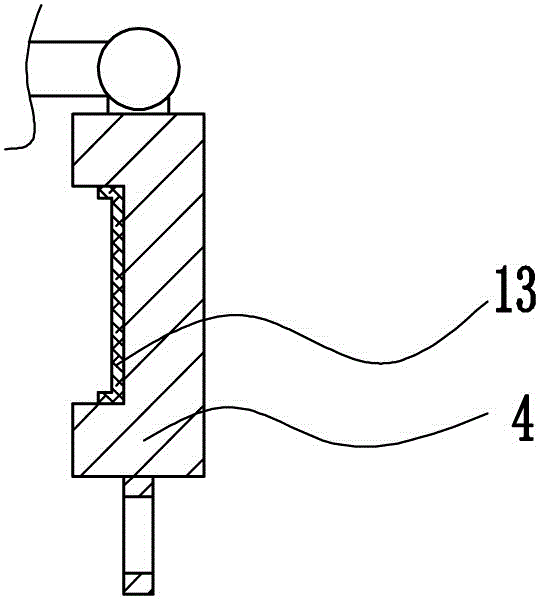

[0034] A kind of polyacrylamide dilution equipment for sewage treatment, such as Figure 1-7 As shown, it includes a bottom plate 1, a supporting rod 2, a dilution frame 3, a discharging mechanism 4, a left frame 5, a top plate 6, a sliding mechanism 7 and a stirring mechanism 8. The top and left sides of the bottom plate 1 are provided with supporting rods 2. The top of the support rod 2 is provided with a dilution frame 3, the bottom of the right wall of the dilution frame 3 is provided with a discharging mechanism 4, the top left end of the bottom plate 1 is provided with a left frame 5, the top of the left frame 5 is provided with a top plate 6, and the bottom of the top plate 6 is provided with a sliding mechanism 7. A stirring mechanism 8 is connected to the sliding mechanism 7.

Embodiment 2

[0036] A kind of polyacrylamide dilution equipment for sewage treatment, such as Figure 1-7 As shown, it includes a bottom plate 1, a supporting rod 2, a dilution frame 3, a discharging mechanism 4, a left frame 5, a top plate 6, a sliding mechanism 7 and a stirring mechanism 8. The top and left sides of the bottom plate 1 are provided with supporting rods 2. The top of the support rod 2 is provided with a dilution frame 3, the bottom of the right wall of the dilution frame 3 is provided with a discharging mechanism 4, the top left end of the bottom plate 1 is provided with a left frame 5, the top of the left frame 5 is provided with a top plate 6, and the bottom of the top plate 6 is provided with a sliding mechanism 7. A stirring mechanism 8 is connected to the sliding mechanism 7.

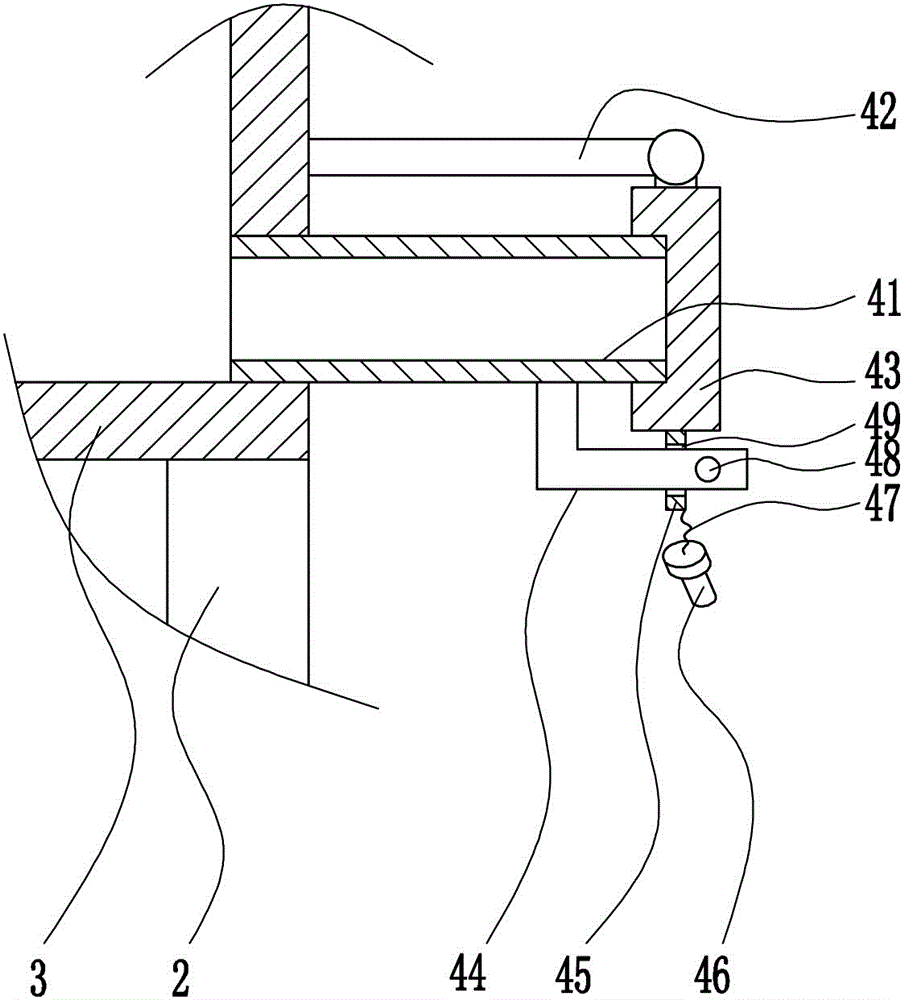

[0037] The discharging mechanism 4 includes a discharging tube 41, a connecting rod 42, a tube cover 43, an L-shaped insert plate 44, a clamping plate 45, a screw 46, and a string 47. The bottom o...

Embodiment 3

[0039] A kind of polyacrylamide dilution equipment for sewage treatment, such as Figure 1-7 As shown, it includes a bottom plate 1, a supporting rod 2, a dilution frame 3, a discharging mechanism 4, a left frame 5, a top plate 6, a sliding mechanism 7 and a stirring mechanism 8. The top and left sides of the bottom plate 1 are provided with supporting rods 2. The top of the support rod 2 is provided with a dilution frame 3, the bottom of the right wall of the dilution frame 3 is provided with a discharging mechanism 4, the top left end of the bottom plate 1 is provided with a left frame 5, the top of the left frame 5 is provided with a top plate 6, and the bottom of the top plate 6 is provided with a sliding mechanism 7. A stirring mechanism 8 is connected to the sliding mechanism 7.

[0040] The discharging mechanism 4 includes a discharging tube 41, a connecting rod 42, a tube cover 43, an L-shaped insert plate 44, a clamping plate 45, a screw 46, and a string 47. The bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com