Cooling units for glass production

A cooling device and glass technology, which is applied in the field of cooling equipment for glass production, can solve the problems of high-temperature glass plates that are easy to burst, waste of water resources, and uneven cooling, so as to prevent bursting due to sudden cold, avoid waste, and improve cooling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

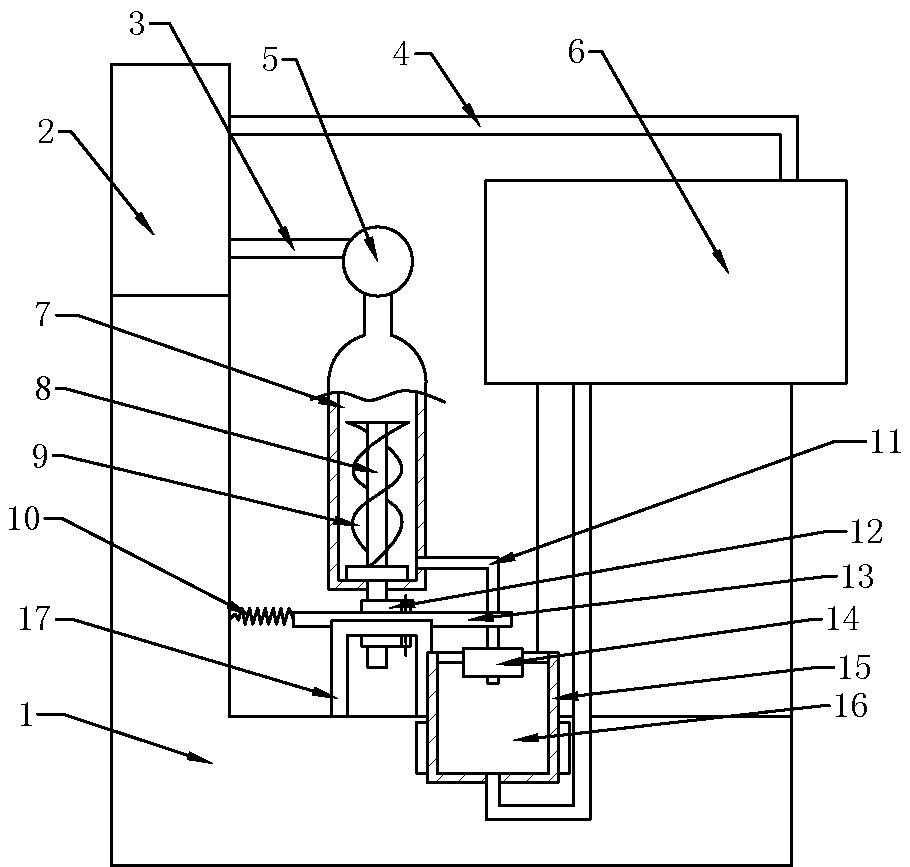

[0020] The reference signs in the drawings of the description include: frame 1, water storage tank 2, water inlet pipe 3, water outlet pipe 4, water pump 5, cooling box 6, water storage tank 7, rotating shaft 8, water wheel 9, compression spring 10, soft Pipe 11, fan gear 12, rack 13, slide block 14, cold water tank 15, cold water plate 16, chute 17.

[0021] Example figure 1 As shown, the cooling device for glass production includes a frame 1 and a cooling box 6. The cooling box 6 is fixed on the frame 1 by bolts. A heat exchange mechanism is welded in the cooling box 6, and the heat exchange mechanism is connected to a water inlet pipe 3 and an outlet pipe. The water pipe 4, the water outlet pipe 4 and the water inlet pipe 3 are successively connected with a water storage tank 2, a water pump 5 and a water cooling mechanism. A belt conveyor is installed in the cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com