1,1-dipyrazolemethane binuclear manganese polymer and its in-situ decarboxylation synthesis method and application

A dipyrazolemethane and synthesis method technology, which is applied in the field of in-situ decarboxylation synthesis of 1,1-dipyrazolemethane binuclear manganese polymers, can solve the problems of low conversion rate and slow reaction speed, and achieve low cost and good conditions Gentle and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

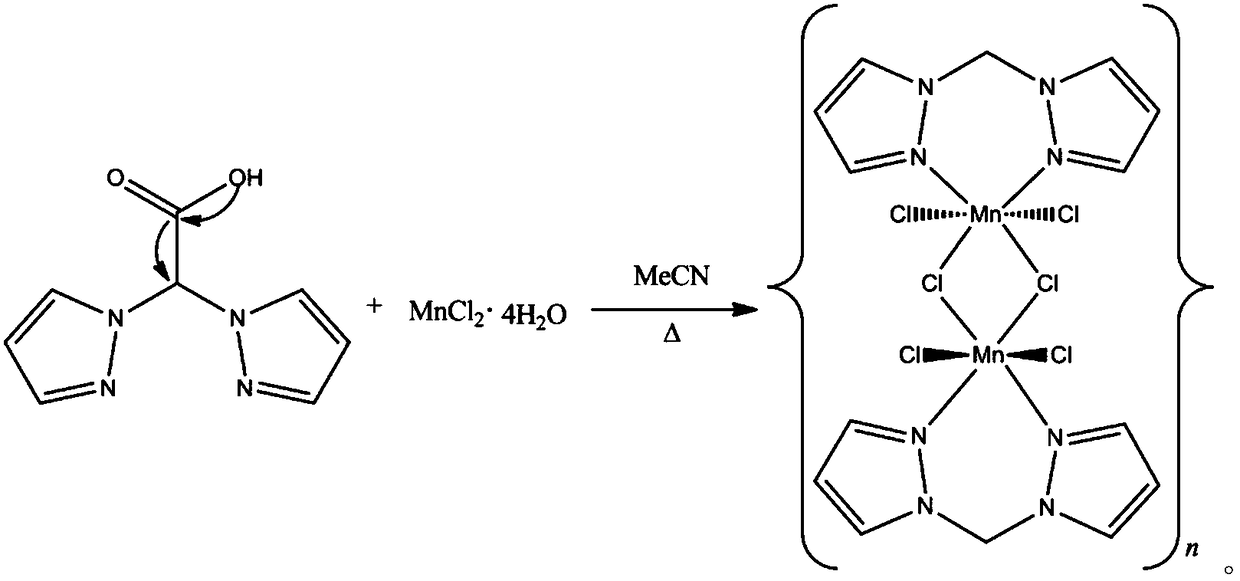

[0025] (1) 0.197 grams of analytically pure MnCl 2 4H 2 O and 0.192 grams of analytically pure 1,1-dipyrazole acetic acid were dissolved in 10 milliliters of anhydrous acetonitrile;

[0026] (2) The solution in step (1) was stirred at room temperature for 5 minutes until all reactants were dissolved and clarified;

[0027] (3) Transfer the solution prepared in step (2) to a polytetrafluoroethylene reactor and react at 110°C for 100 hours, cool down to room temperature, open the kettle, filter, and wash with anhydrous acetonitrile to obtain single crystal grade 1,1 -Dipyrazolemethane binuclear manganese polymer, yield 78-85%.

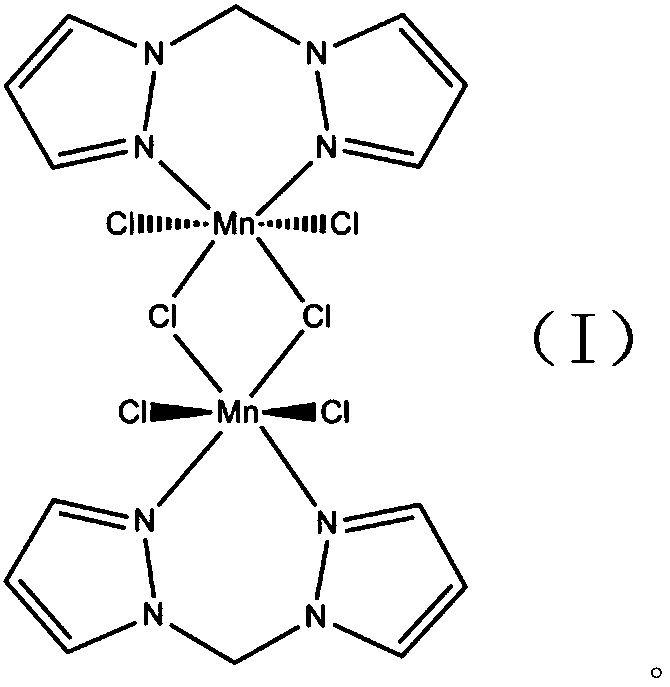

[0028] And confirm its structural formula with X-ray single crystal diffraction, infrared spectrum, mass spectrum, nuclear magnetic resonance proton spectrum / carbon spectrum as:

[0029]

[0030] The basic data of the resulting 1,1-dipyrazolemethane binuclear manganese polymers were analyzed:

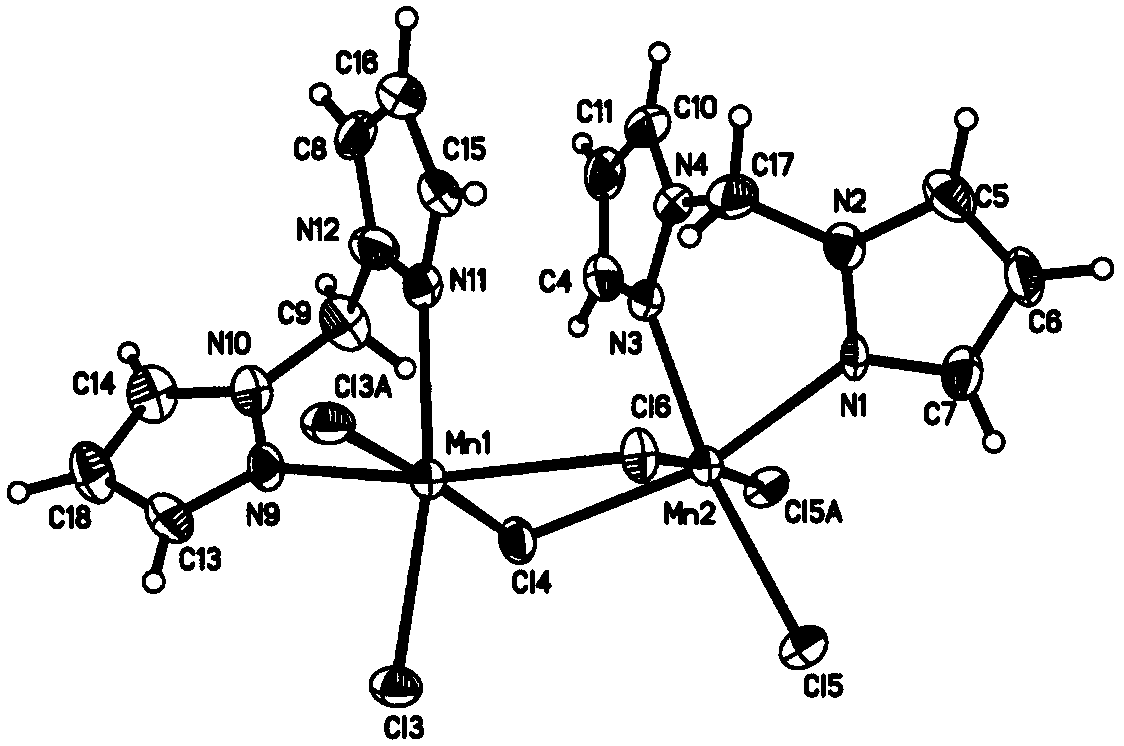

[0031] X-ray single crystal diffraction characterizat...

Embodiment 2

[0033] (1) 0.256 gram of analytically pure MnCl 2 4H 2 O and 0.245 grams of analytically pure 1,1-dipyrazole acetic acid were dissolved in 12 milliliters of anhydrous acetonitrile;

[0034] (2) The solution in step (1) was stirred at room temperature for 5 minutes until all reactants were dissolved and clarified;

[0035] (3) Transfer the solution prepared in step (2) to a polytetrafluoroethylene reactor and react at 120°C for 120 hours, cool down to room temperature, open the kettle, filter, and wash with anhydrous acetonitrile to obtain single crystal grade 1,1 -Dipyrazolemethane binuclear manganese polymer, yield 78-85%.

Embodiment 3

[0037] (1) 0.380 gram of analytically pure MnCl 2 4H 2 O and 0.360 grams of analytically pure 1,1-dipyrazole acetic acid are dissolved in 15 milliliters of anhydrous acetonitrile;

[0038] (2) Stir the solution in step (1) at room temperature for 10 minutes until all reactants are dissolved and clarified;

[0039] (3) Transfer the solution prepared in step (2) to a polytetrafluoroethylene reactor and react at 140°C for 150 hours, cool down to room temperature, open the kettle, filter, and wash with anhydrous acetonitrile to obtain single crystal grade 1,1 -Dipyrazolemethane binuclear manganese polymer, yield 78-85%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap