Fully automatic heat treatment industrial furnace

An industrial furnace, fully automatic technology, used in heat treatment furnaces, heat treatment equipment, heat treatment process control and other directions, can solve the problems that cannot be installed in the furnace body, the heating workpiece is difficult to achieve the same temperature, the operation is laborious and laborious, and the surface of the shell can be guaranteed. The temperature and graphic operation interface is convenient, and the effect of preventing uneven force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

[0071] In order to solve the above technical problems, the fully automatic heat treatment industrial furnace of the present invention adopts the following technical solutions:

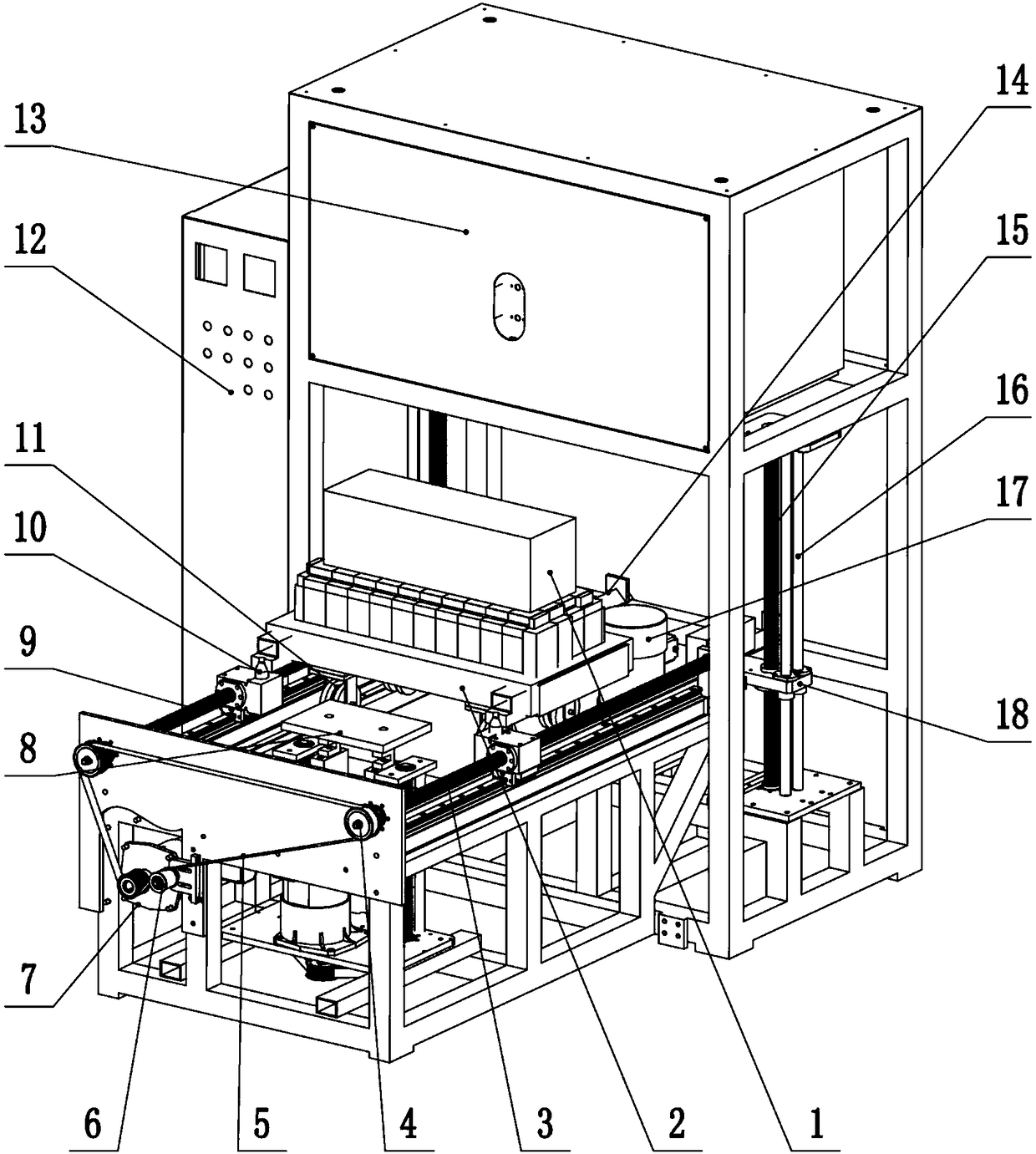

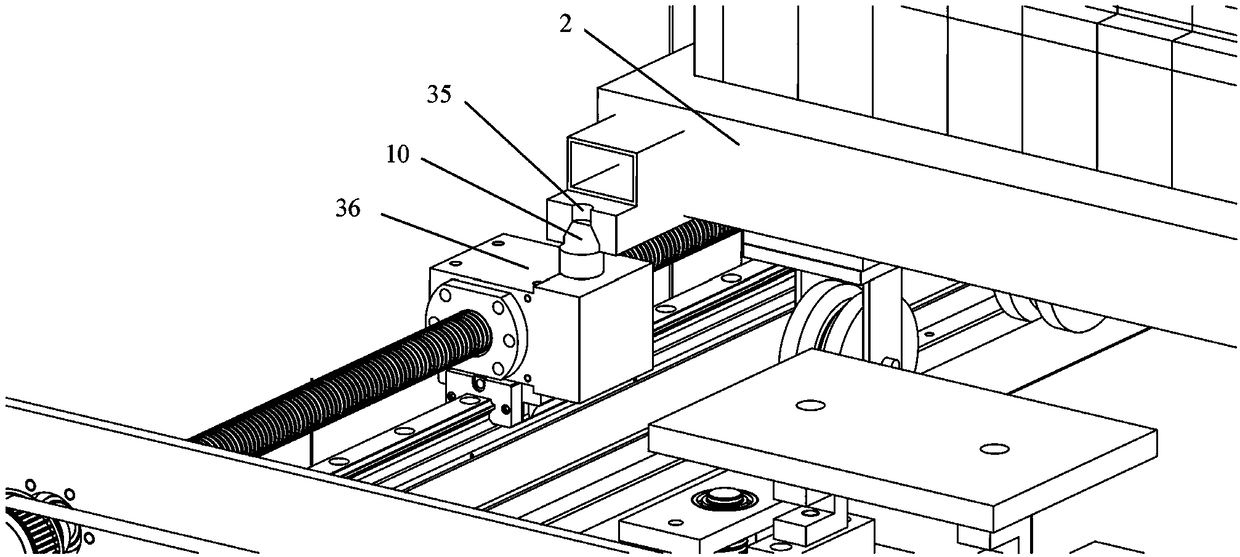

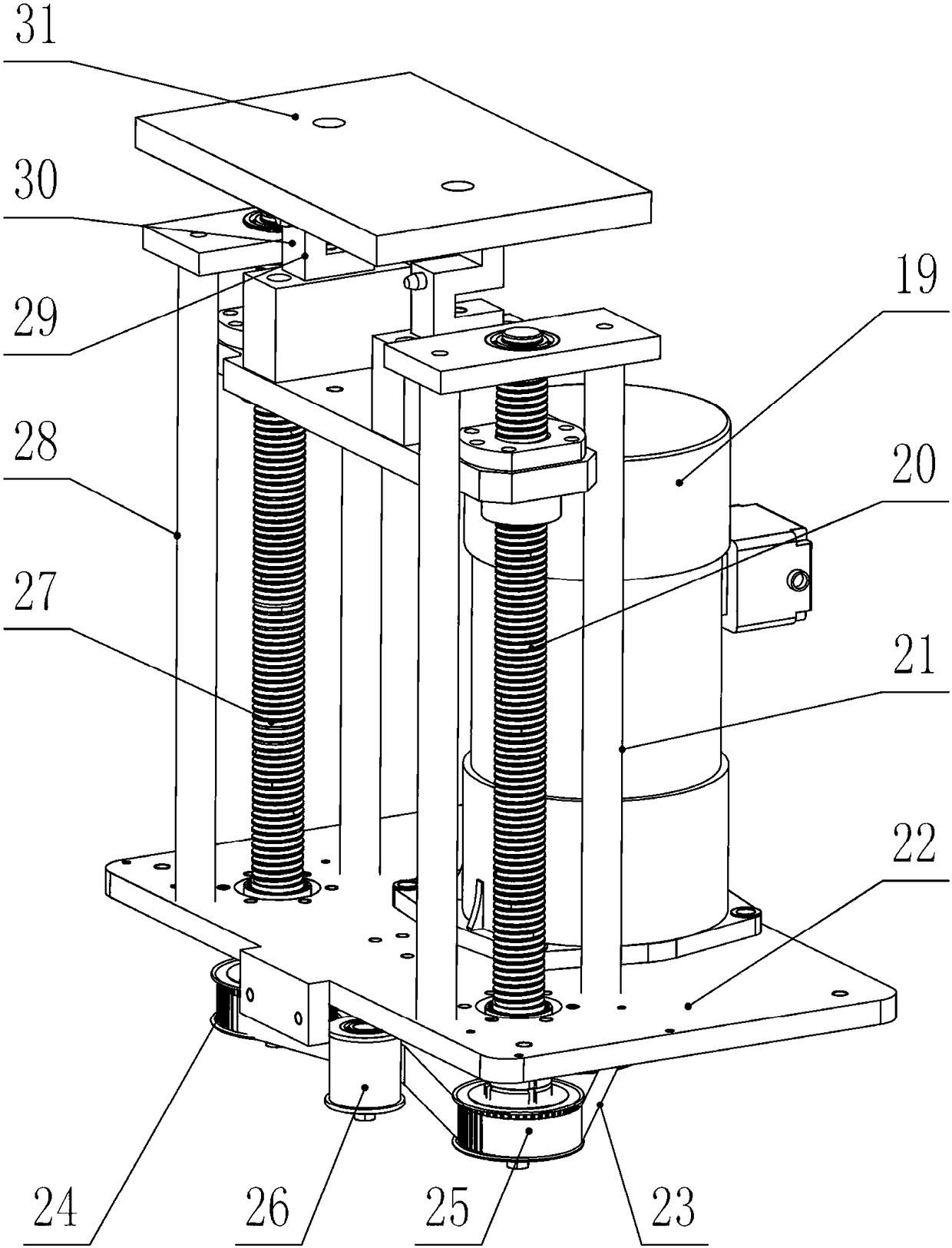

[0072] like figure 1 As shown, it consists of workpiece, mobile trolley, translation drive mechanism, lifting drive mechanism, heating furnace, automatic weighing mechanism and automatic control system. The workpiece 1 is placed on the mobile trolley 2, and the mobile trolley 2 is equipped with a multi-layer refractory brick building insulation plate that can carry the workpiece 1, and can perform translation and lifting movements under the control of the automatic control system. There are 4 rollers 11 at the bottom of the mobile trolley 2. Preferably, V-shaped rollers can be used. Driven by the translation drive motor 7, the sync...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap