Link-lever structured laser coaxial powder-feeding nozzle with adjustable powder gathering point

A coaxial powder feeding, lever-type technology, applied in the direction of metal material coating process, coating, etc., can solve the problem of molding efficiency, low utilization rate of powder convergence powder, inability to achieve high precision, high quality cladding layer, Limit the promotion and application of laser cladding technology, and achieve the effect of variable cladding track width, simple and reasonable structure, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

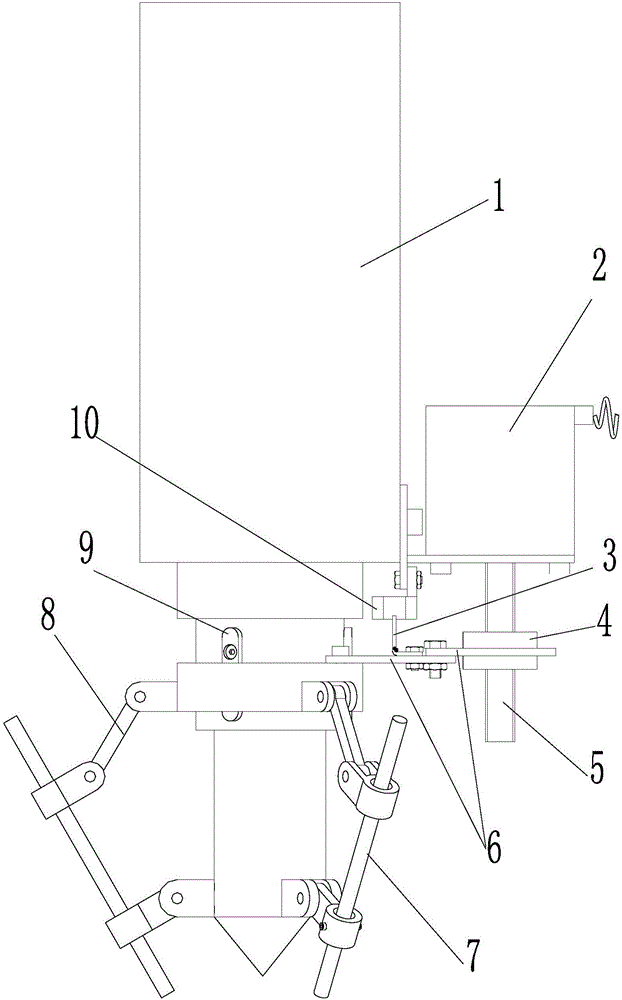

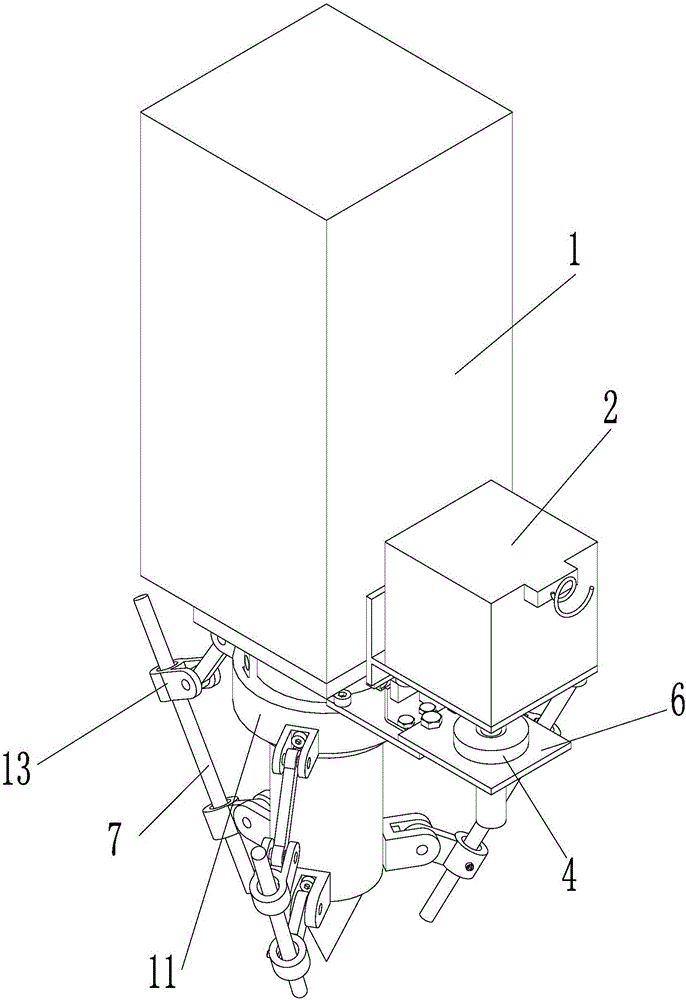

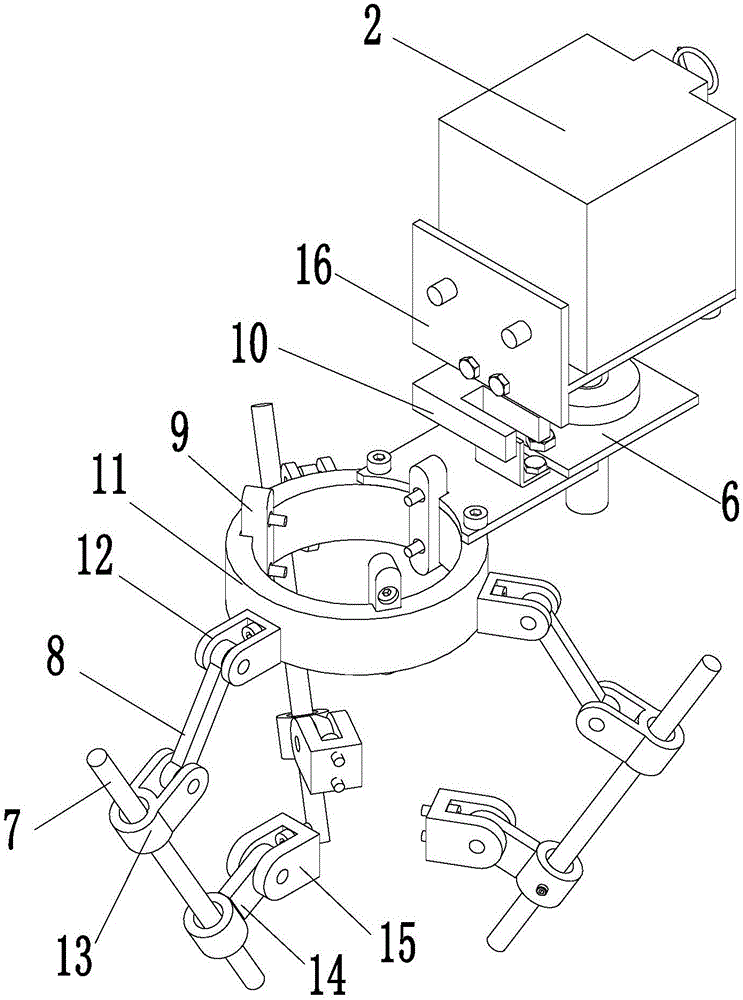

[0029] Referring to the drawings, a laser coaxial powder feeding nozzle with adjustable connecting rod lever structure powder convergence point includes a cladding head 1. A laser inlet is provided above the cladding head 1 in a vertical direction. The cover is provided with a laser exit along the vertical direction; the laser beam of the laser enters from the laser entrance and exits from the laser exit to converge on the surface of the processed part

[0030] The cladding head 1 is provided with a powder feeding tube 7 which is installed around the cladding head 1 through an angle adjustment device that can adjust the angle between the powder feeding tube 7 and the cladding head 1; The exit of 7 is downward and close to the laser exit, and the extension line of the central axis of the powder feeding tube 7 intersects the extension line of the central axis of the cladding head 1 to ensure that the laser from the laser exit and the exit from the powder feeding tube 7 The powder g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com