Patents

Literature

40results about How to "Variable width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

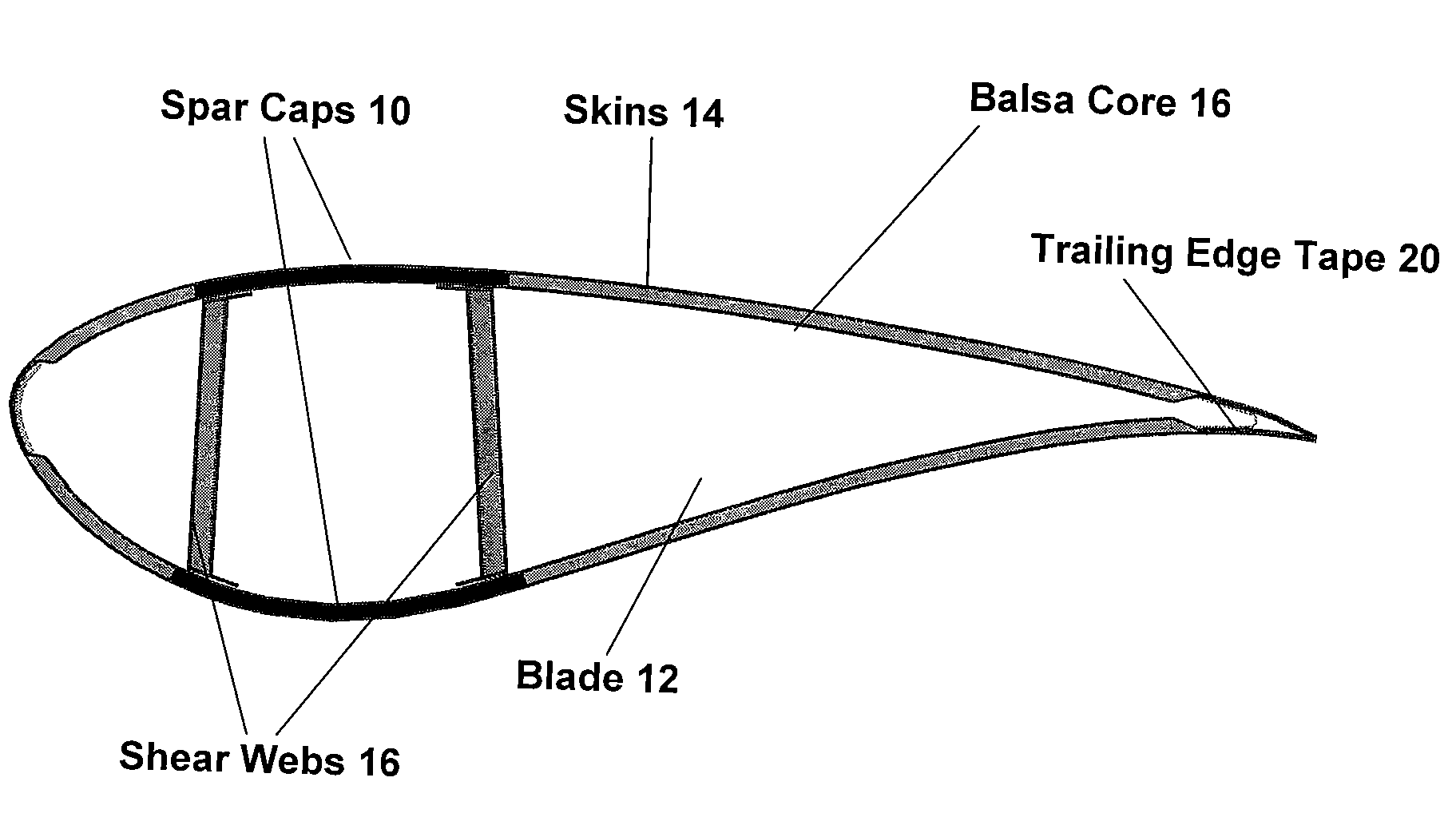

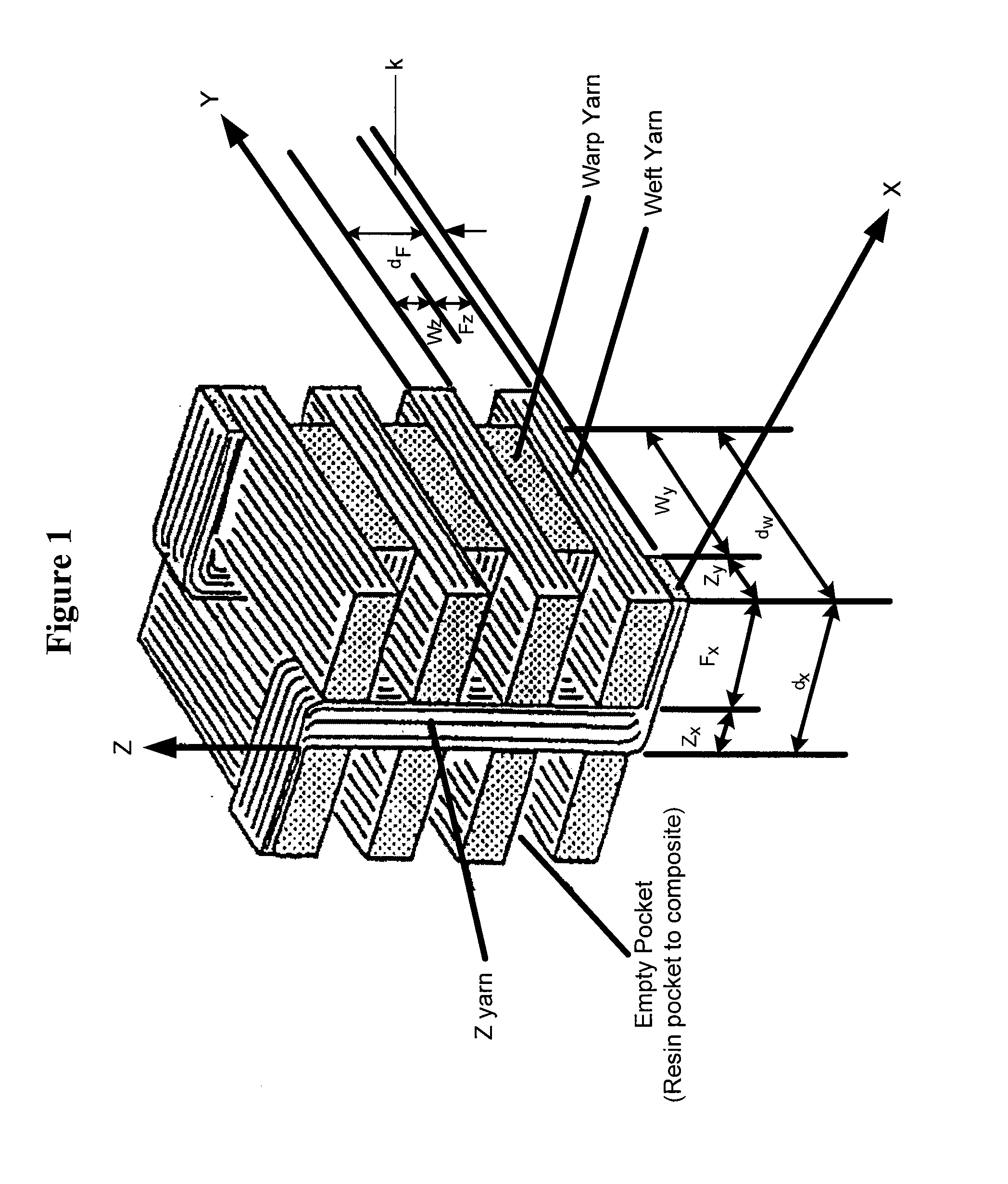

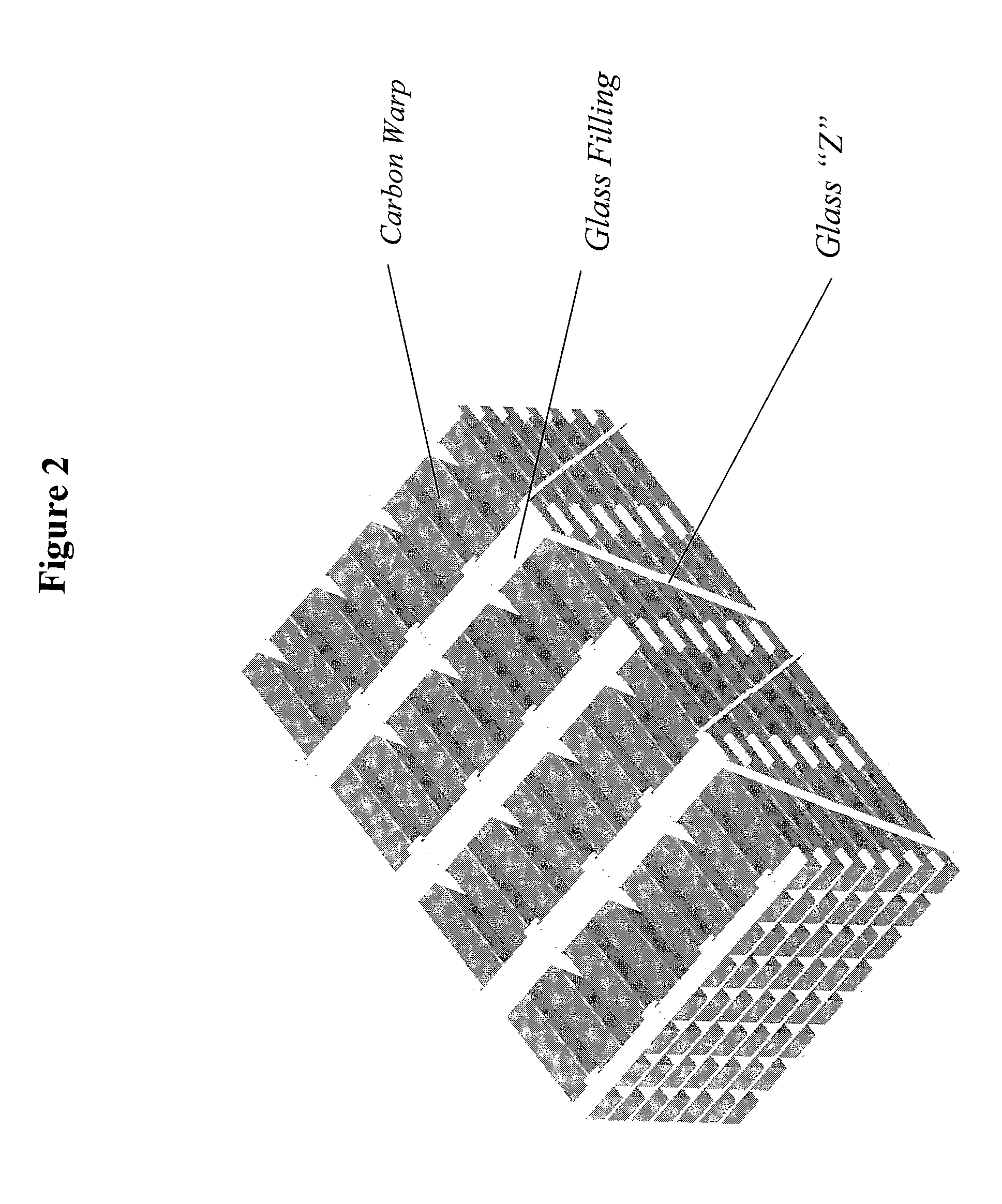

Wind blade spar cap and method of making

InactiveUS20070189902A1Constant thicknessReduce weightRotary propellersFinal product manufactureDecrease weightEngineering

Owner:3TEX

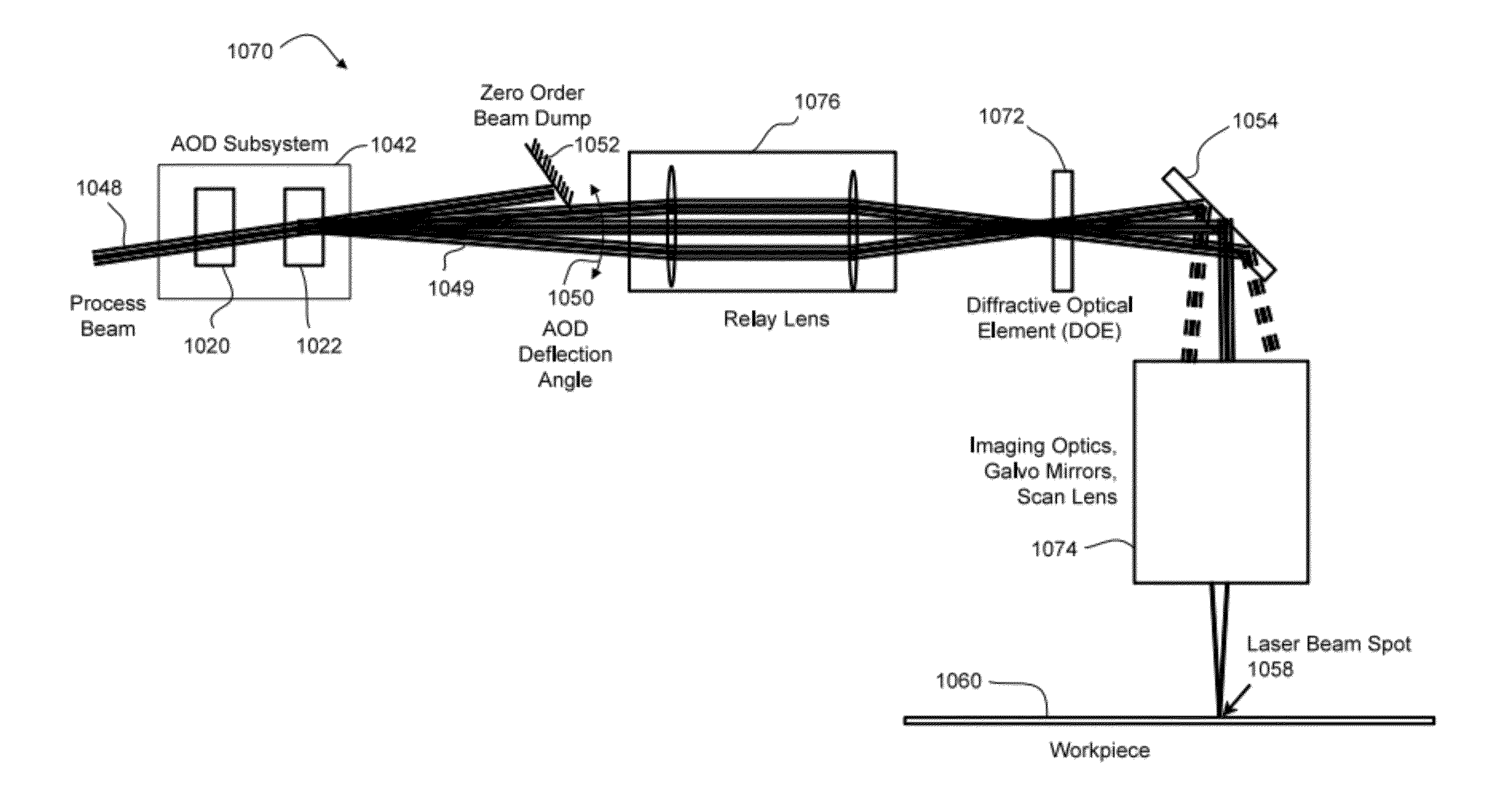

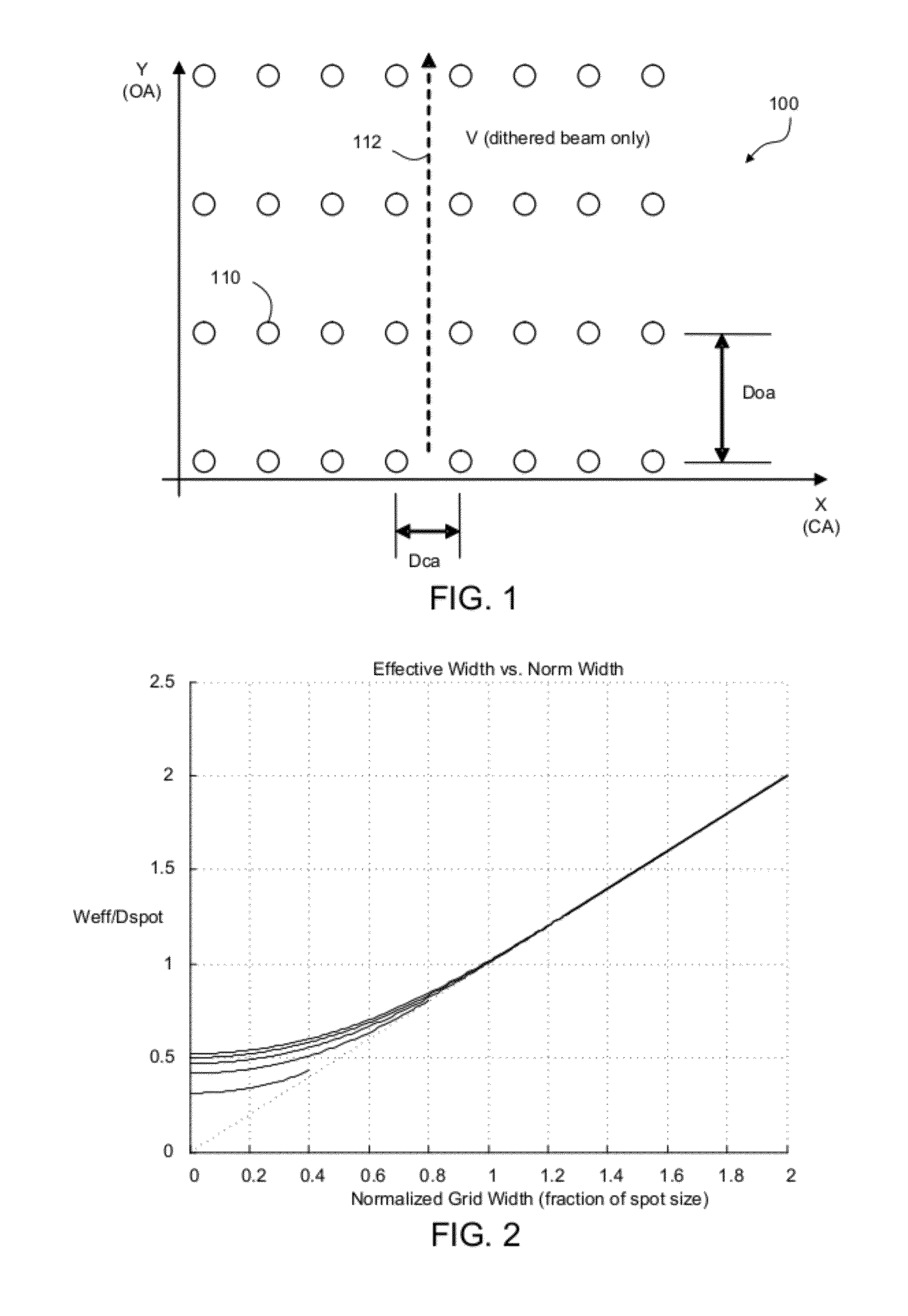

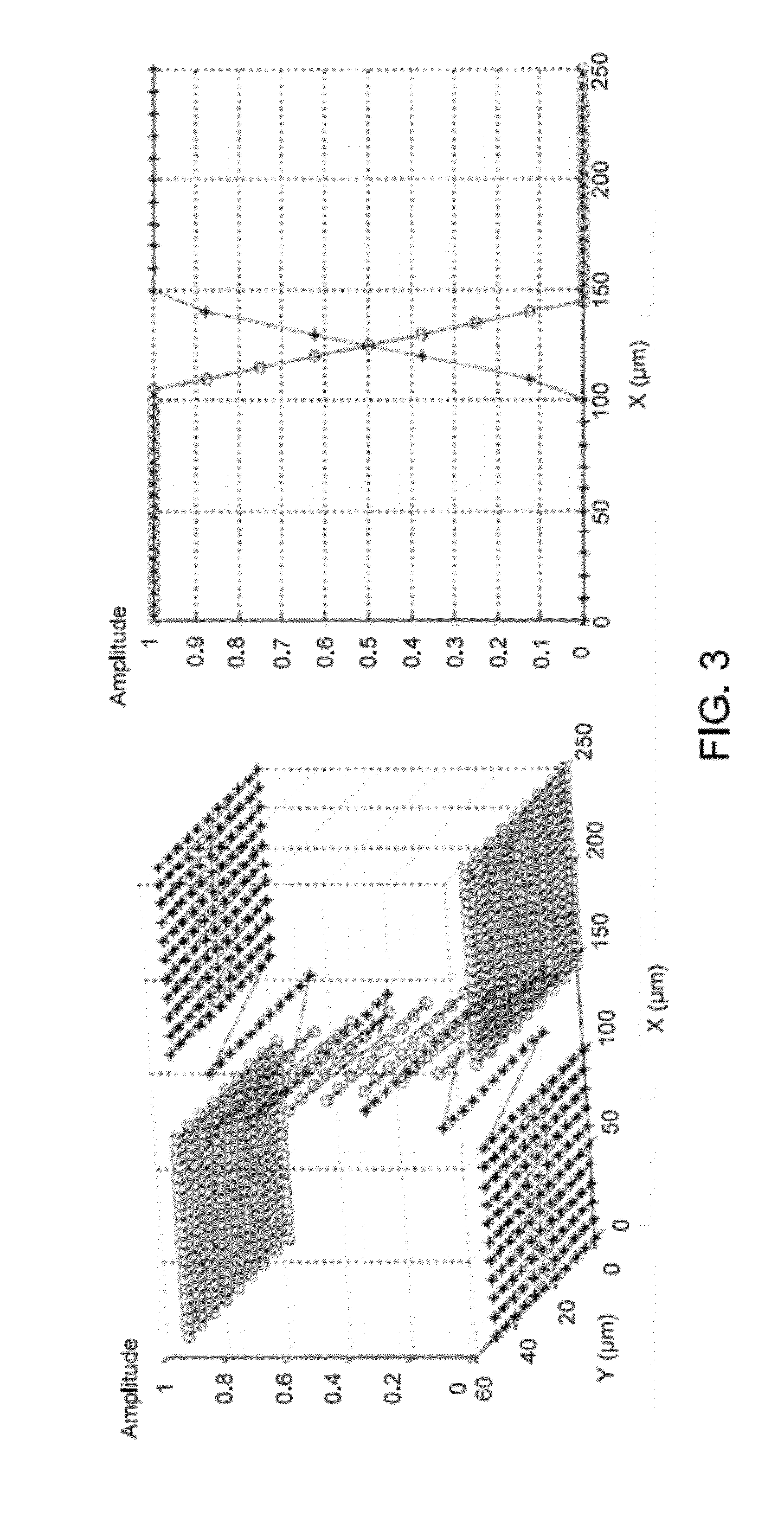

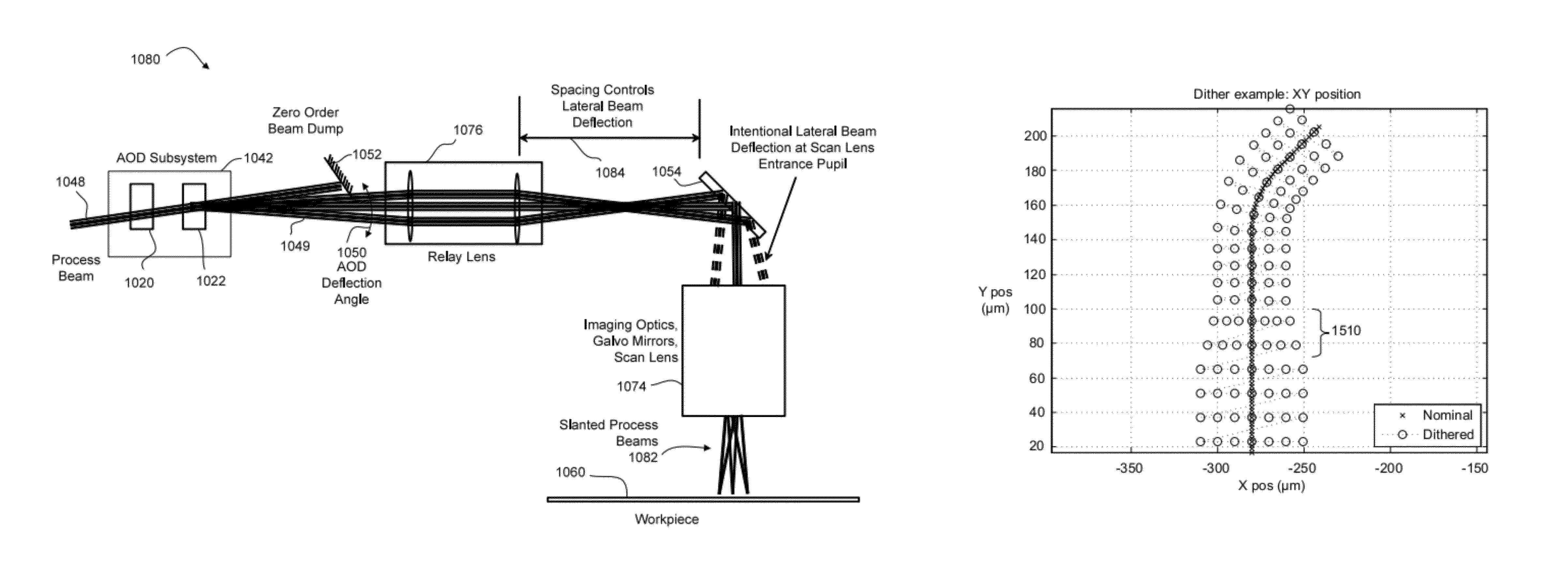

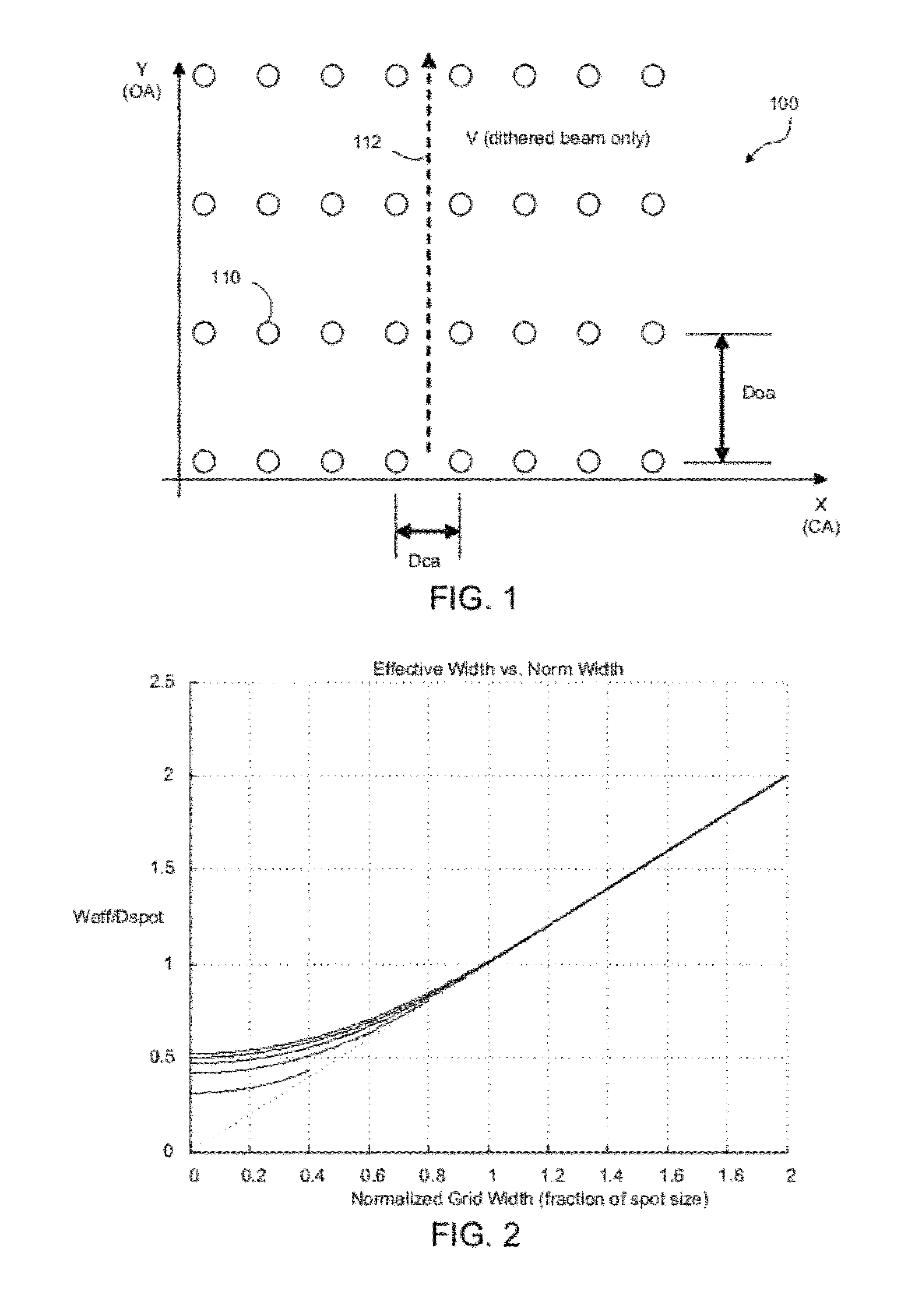

Laser processing systems and methods for beam dithering and skiving

ActiveUS20120273472A1Shorten the timeWidth of trench is variableSemiconductor/solid-state device manufacturingAuxillary shaping apparatusLaser processingBeam trajectory

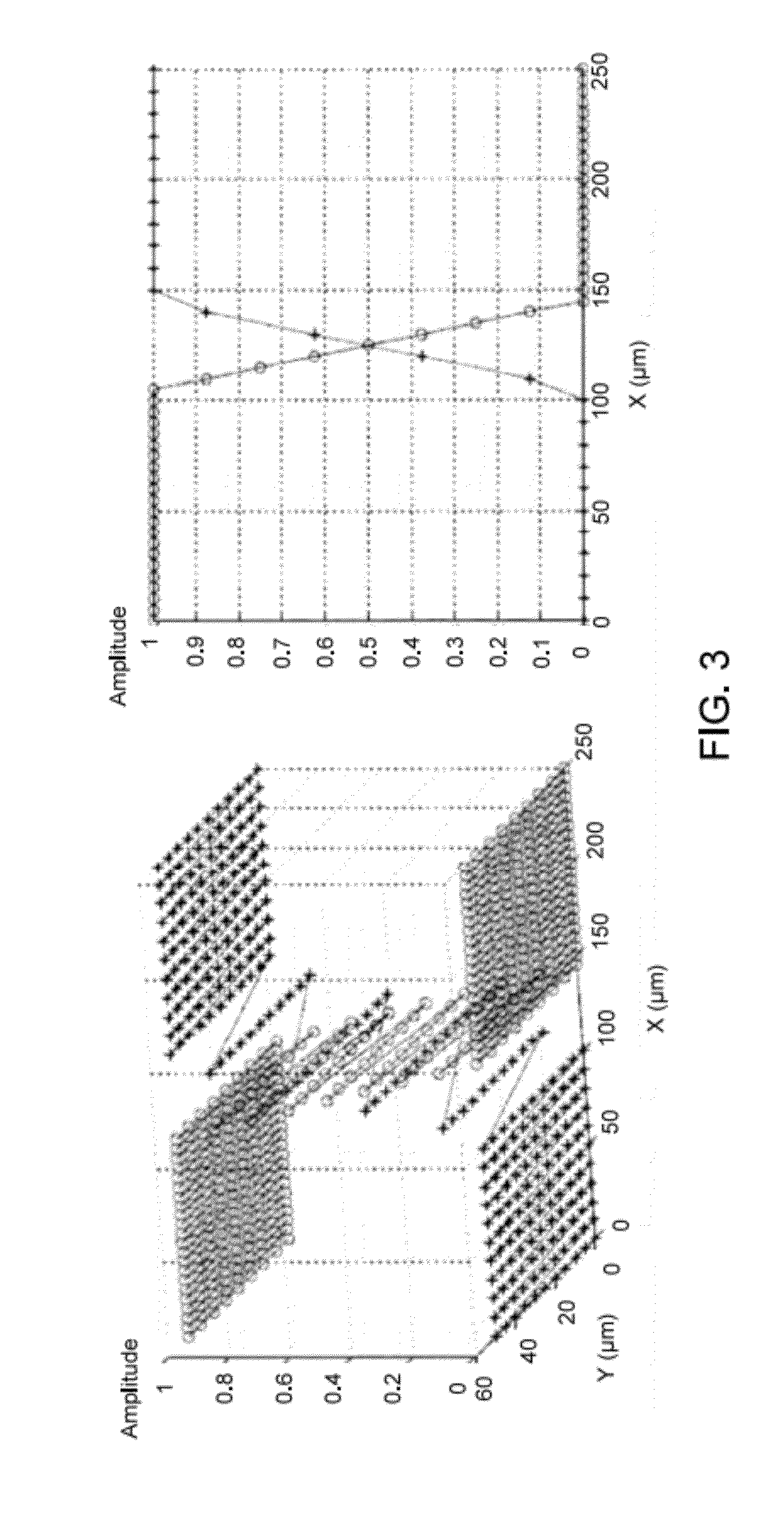

A laser processing system includes a first positioning system for imparting first relative movement of a beam path along a beam trajectory with respect to a workpiece, a processor for determining a second relative movement of the beam path along a plurality of dither rows, a second positioning system for imparting the second relative movement, and a laser source for emitting laser beam pulses. The system may compensate for changes in processing velocity to maintain dither rows at a predetermined angle. For example, the dither rows may remain perpendicular to the beam trajectory regardless of processing velocity. The processing velocity may be adjusted to process for an integral number of dither rows to complete a trench. A number of dither points in each row may be selected based on a width of the trench. Fluence may be normalized by adjusting for changes to processing velocity and trench width.

Owner:ELECTRO SCI IND INC

Laser processing systems and methods for beam dithering and skiving

ActiveUS8847113B2Shorten the timeVariable widthSemiconductor/solid-state device manufacturingCAD circuit designLaser processingBeam trajectory

A laser processing system includes a first positioning system for imparting first relative movement of a beam path along a beam trajectory with respect to a workpiece, a processor for determining a second relative movement of the beam path along a plurality of dither rows, a second positioning system for imparting the second relative movement, and a laser source for emitting laser beam pulses. The system may compensate for changes in processing velocity to maintain dither rows at a predetermined angle. For example, the dither rows may remain perpendicular to the beam trajectory regardless of processing velocity. The processing velocity may be adjusted to process for an integral number of dither rows to complete a trench. A number of dither points in each row may be selected based on a width of the trench. Fluence may be normalized by adjusting for changes to processing velocity and trench width.

Owner:ELECTRO SCI IND INC

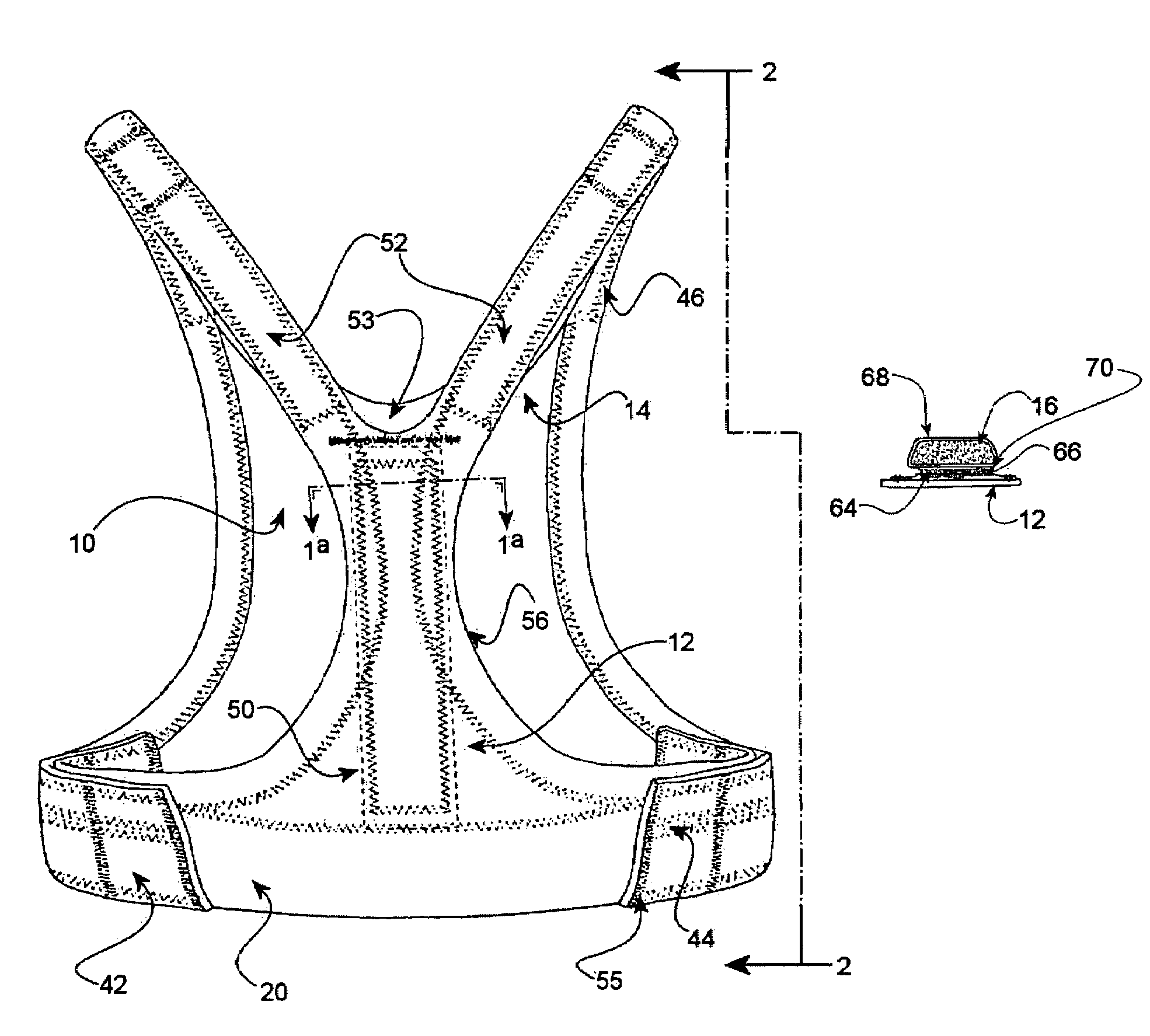

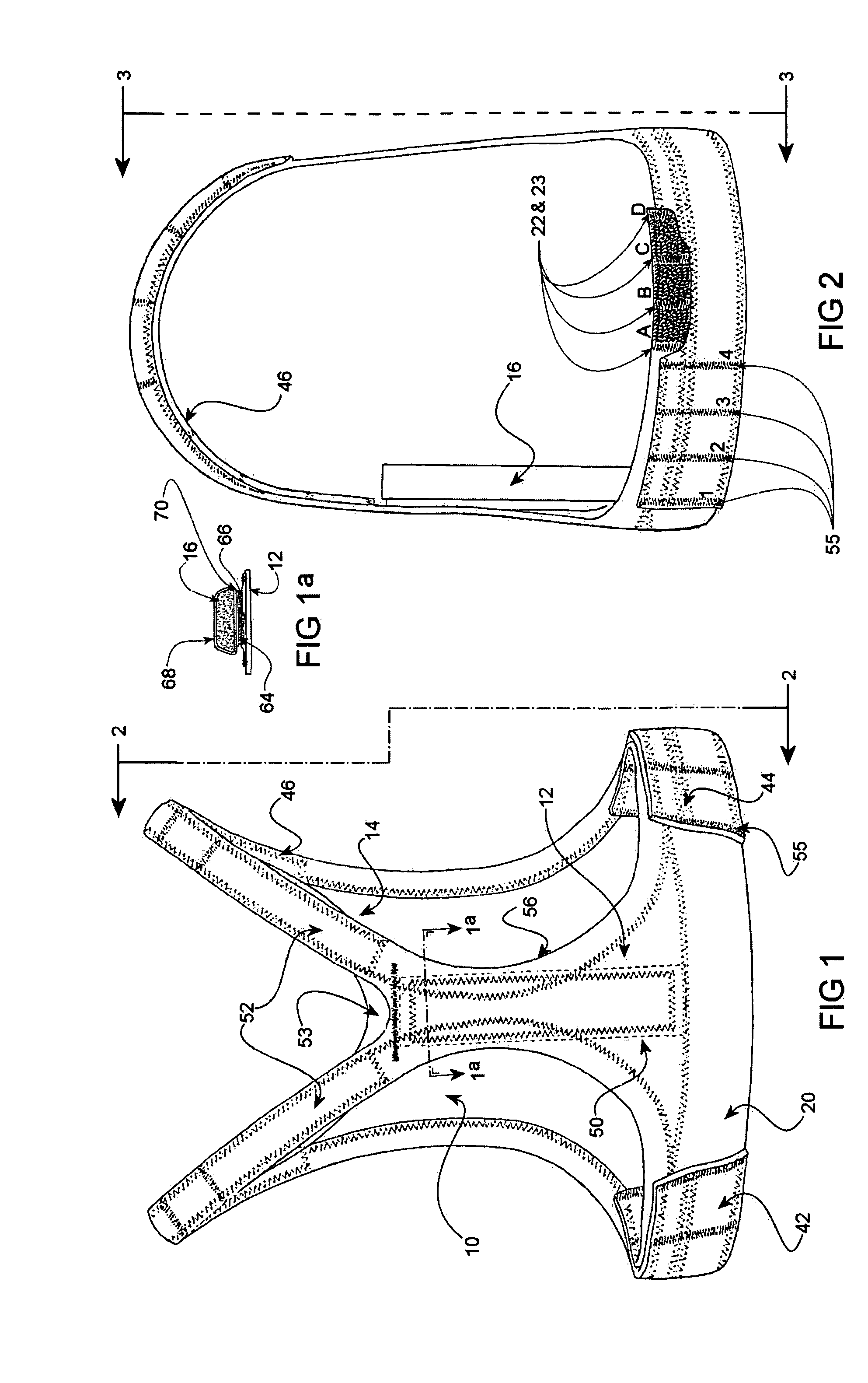

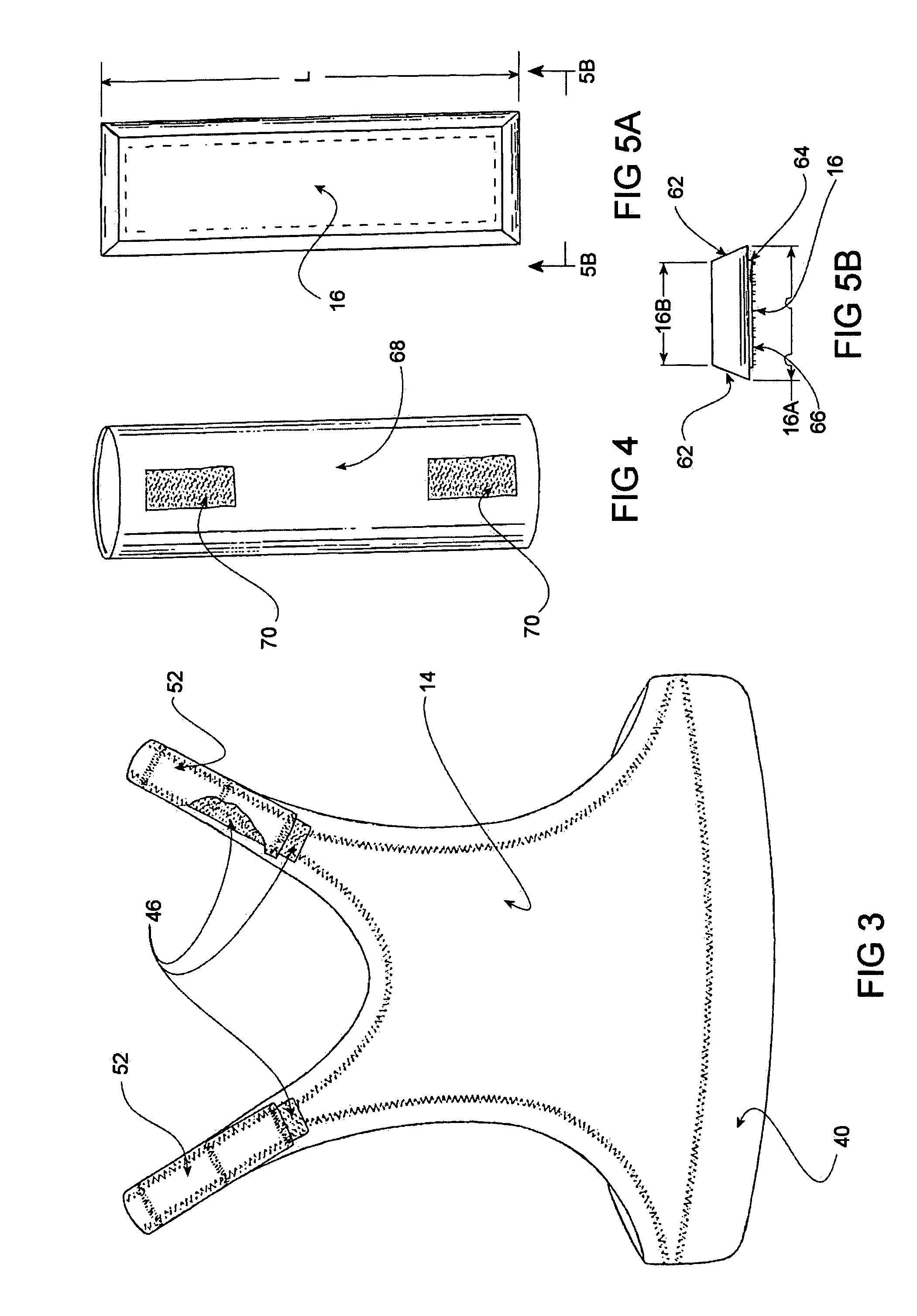

Post surgical chest support garment

This invention is directed to patients who need vertical support in the cleavage area due to symmastia repair or reconstruction of the chest cleavage for breast reconstruction after mastectomy. The support garment is designed not to support the breast or nipple area of the chest. The Y support which fits the patient close to the neck and between the breasts is attached to a full back panel using self adjusting velcro closures. This unique design creates a force much like a bow to provide constant pressure from front to back on the cleavage area only to allow scar tissue to form during the healing process. The cross link high density foam insert maintains even pressure during healing and does not lose its resiliency or permit permanent deformation.

Owner:THONGBRA INC

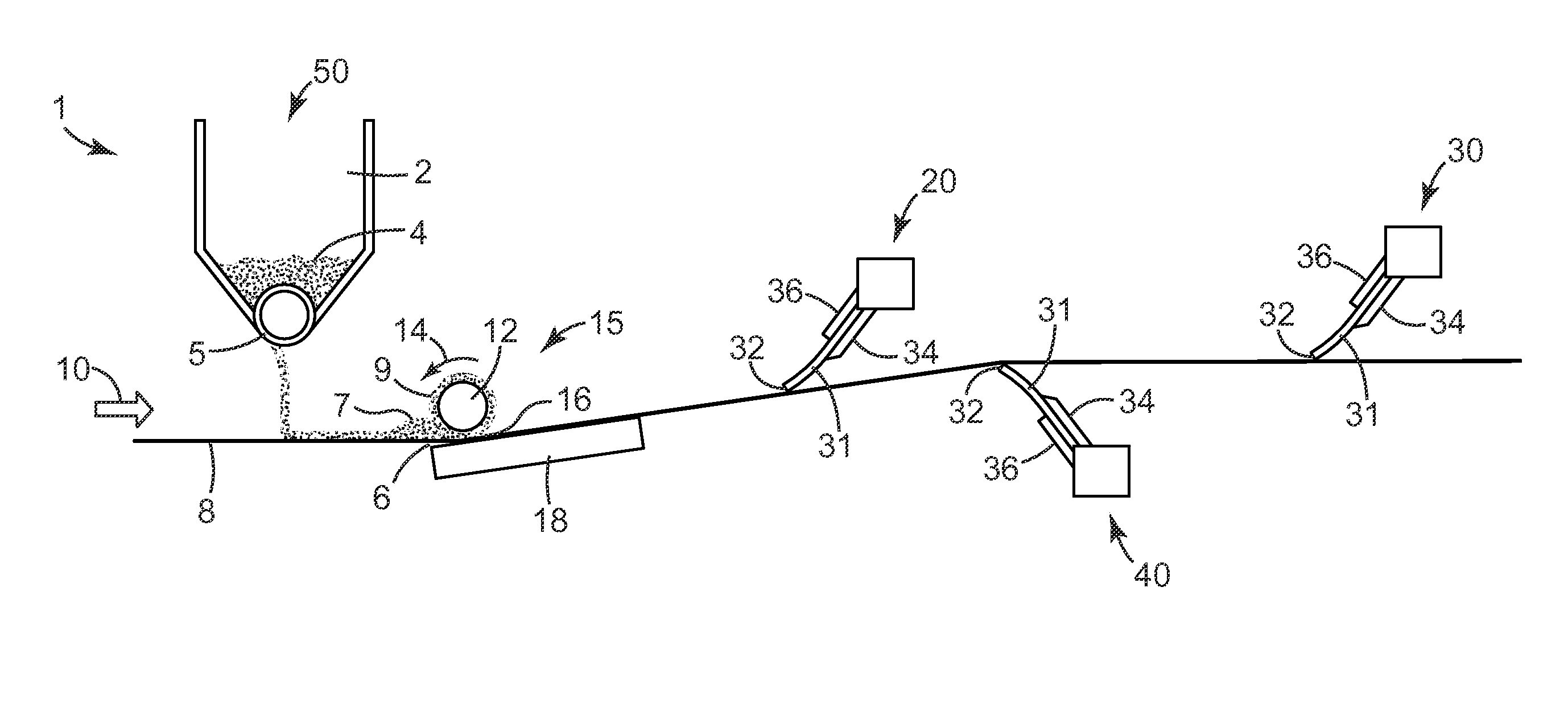

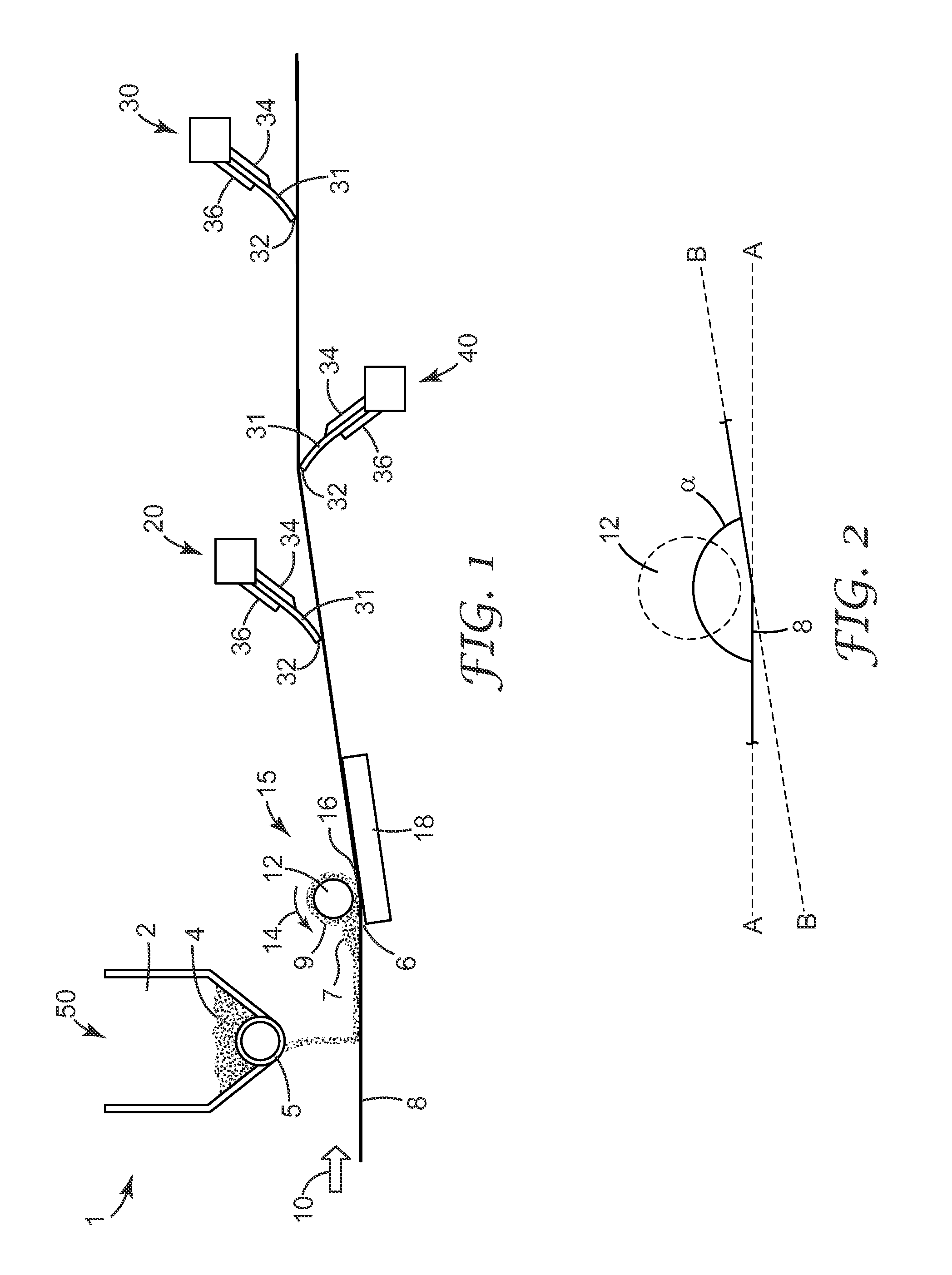

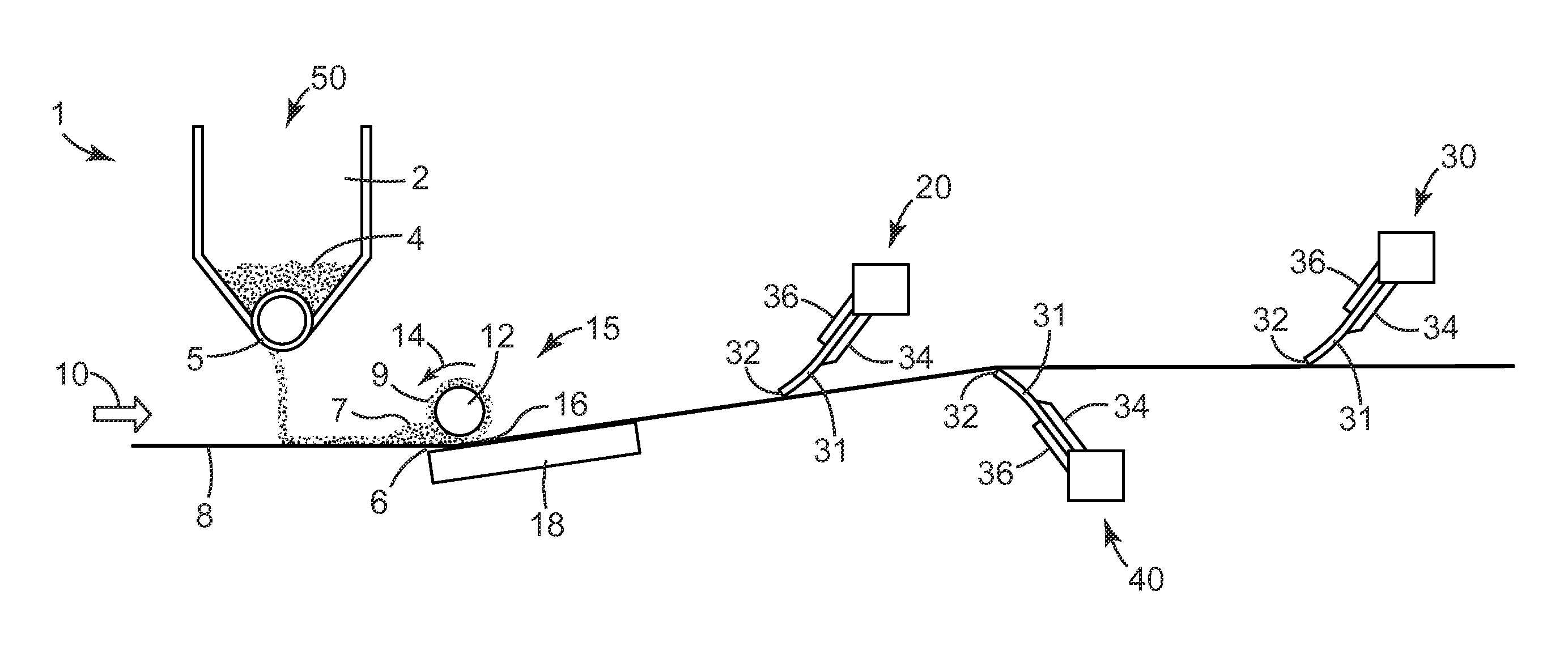

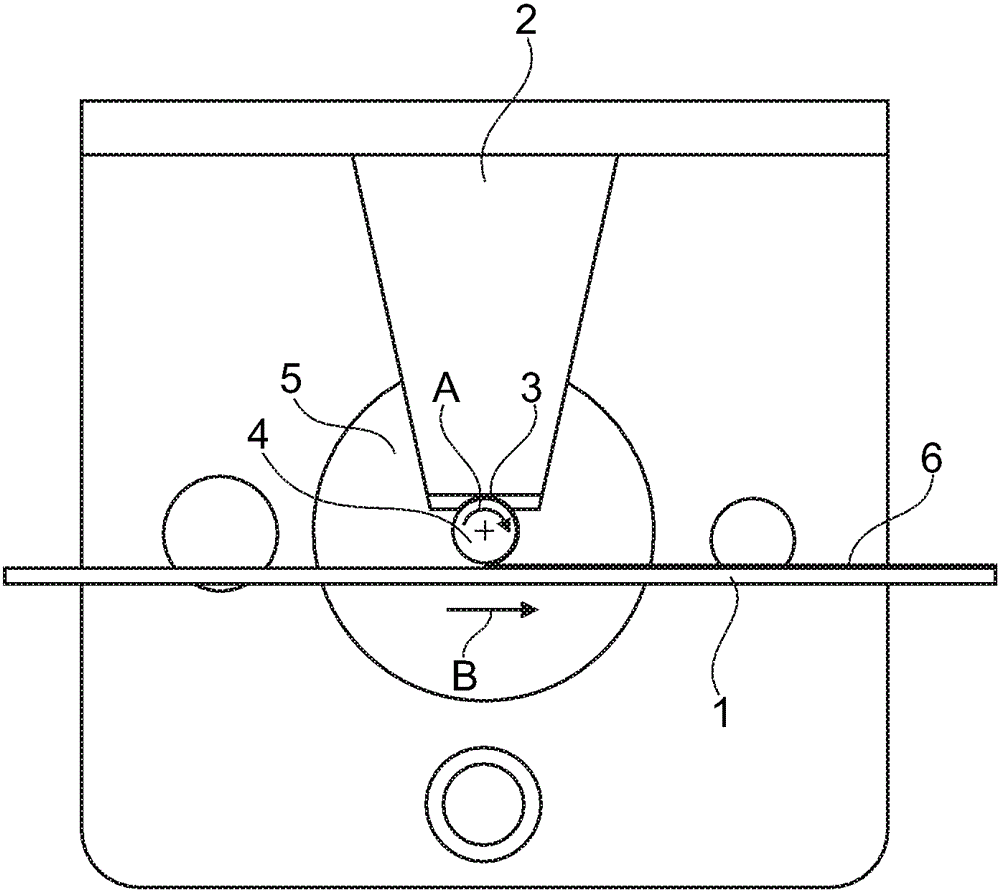

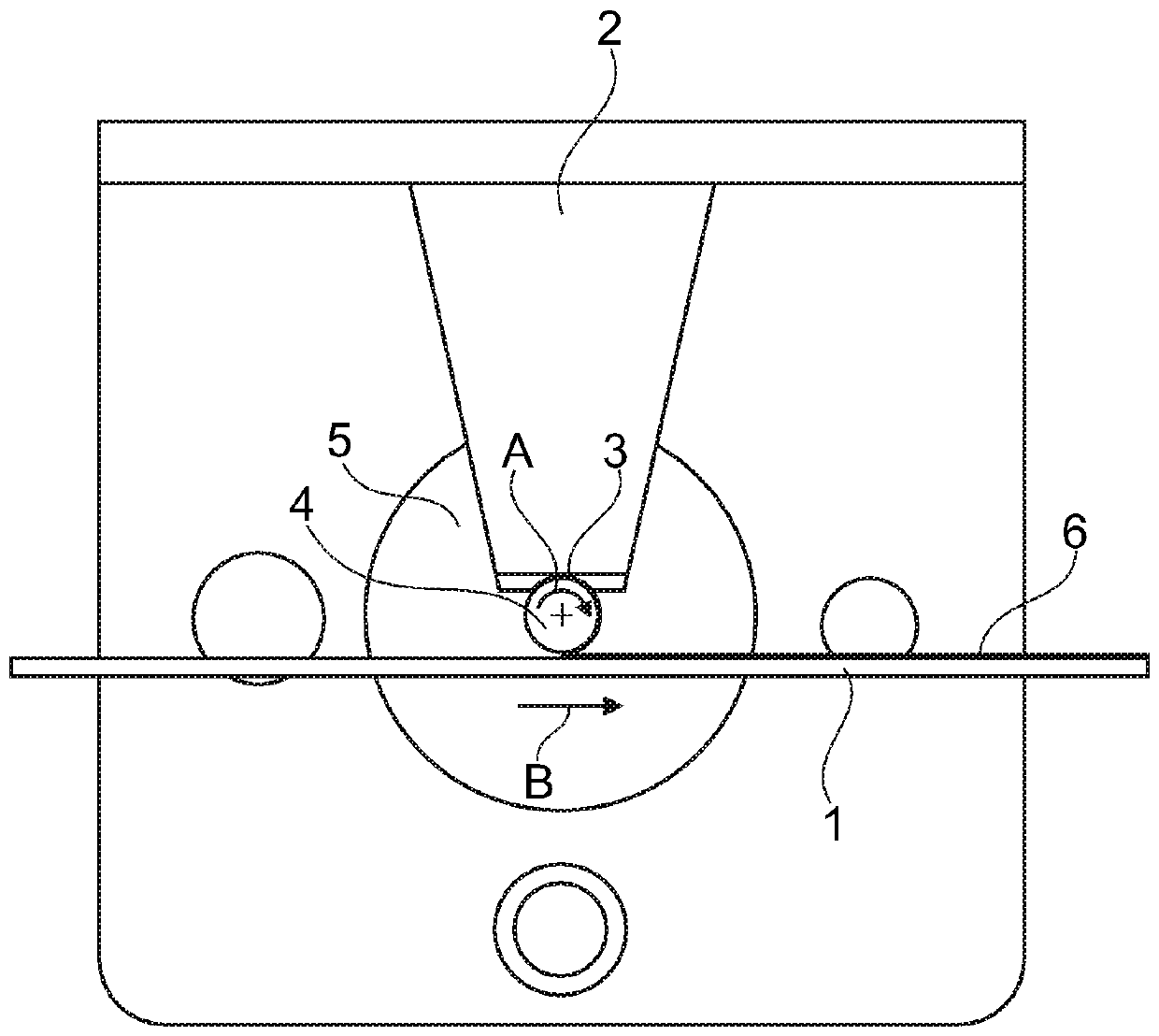

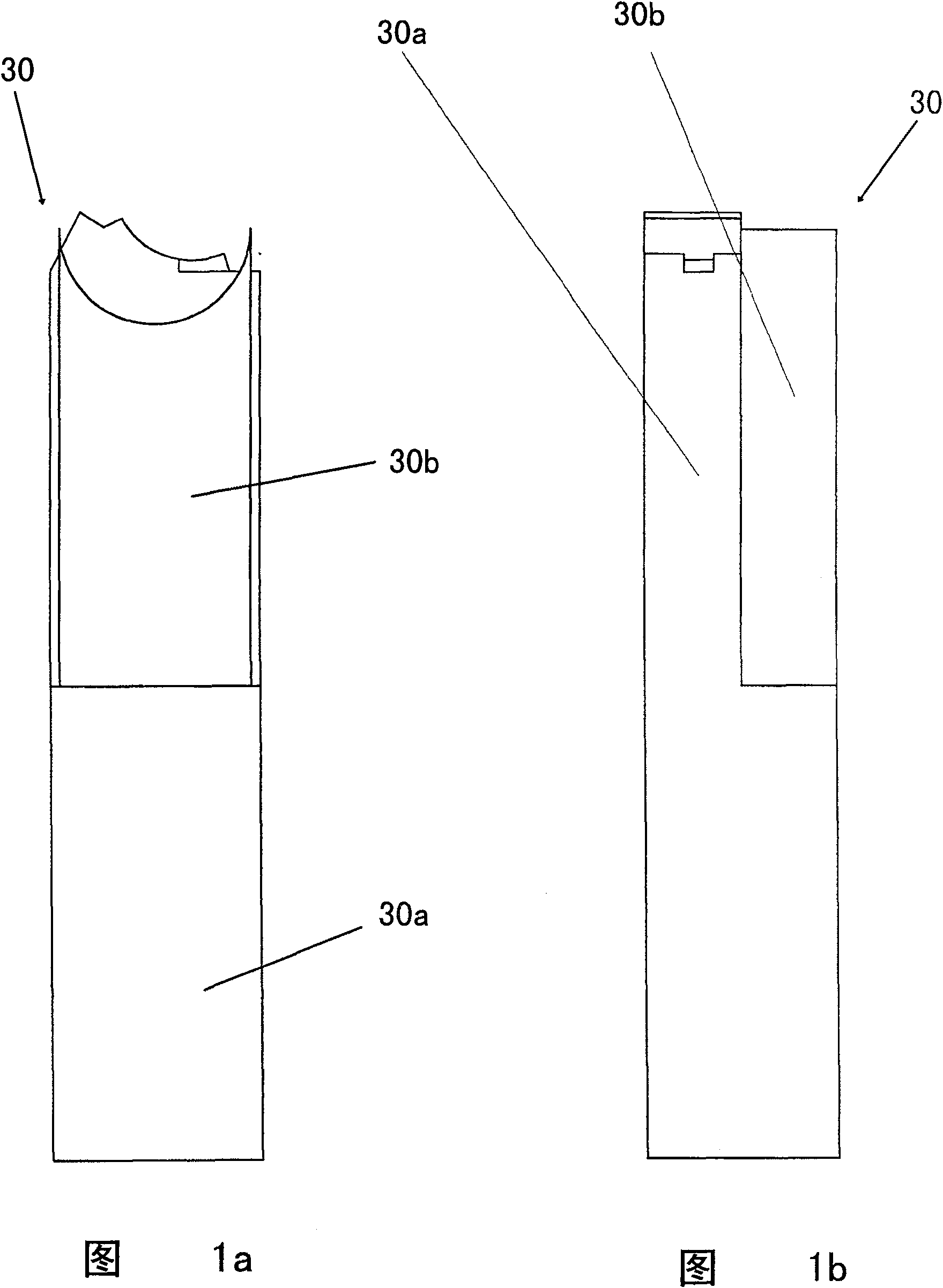

Powder filling processes

ActiveUS20100229859A1Suitable for useFacilitate prevention of formationRespiratorsPowder deliverySurface velocityEngineering

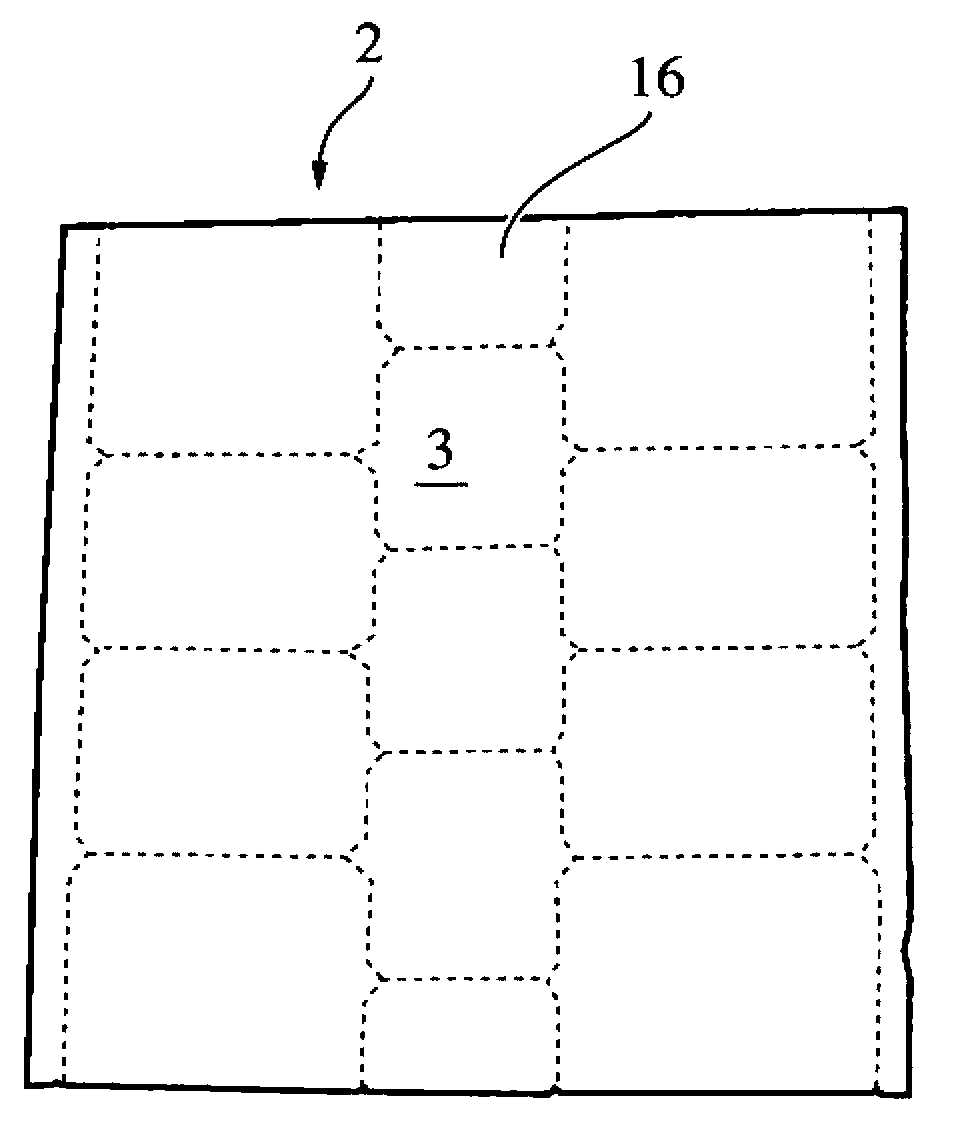

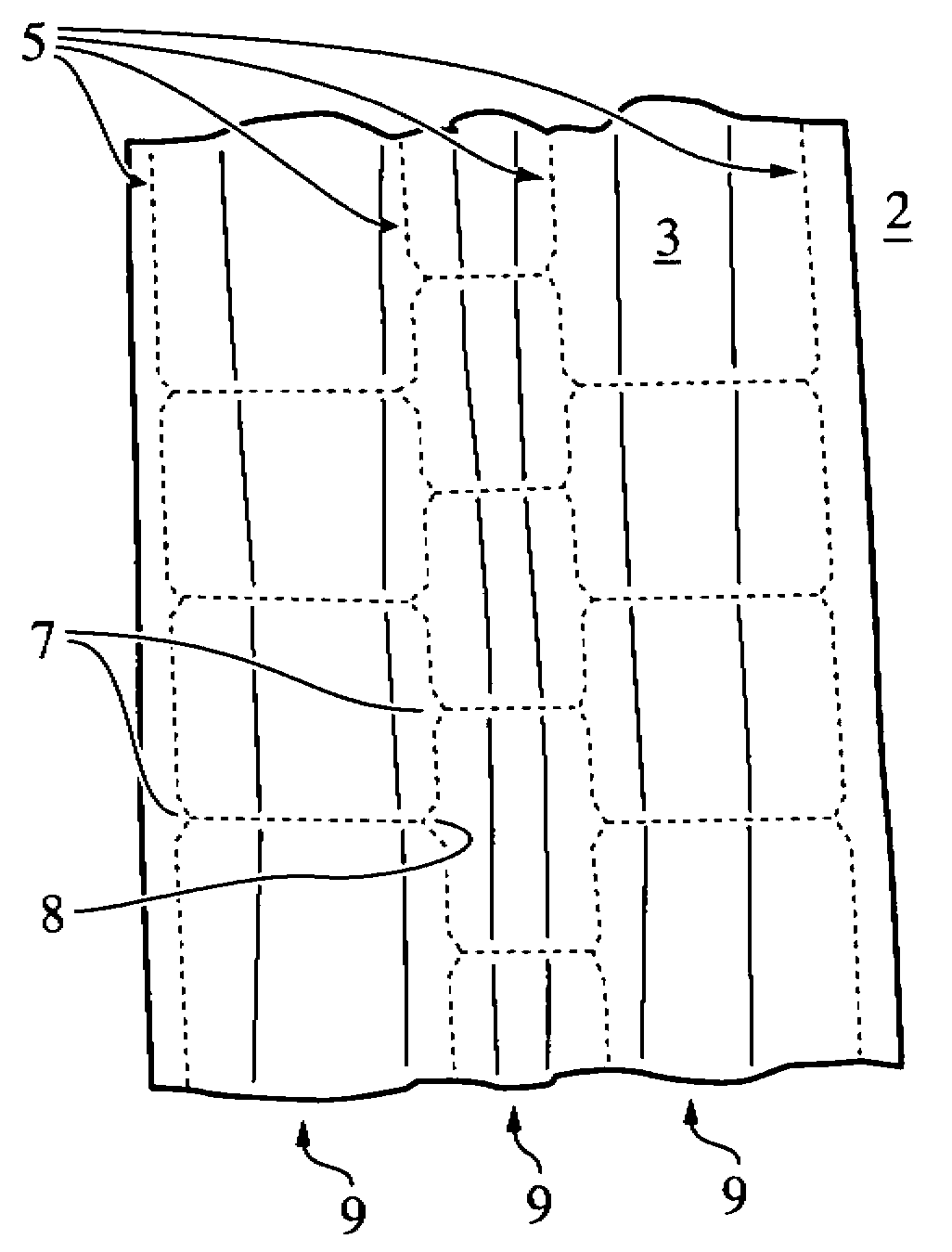

A method for filling a plurality of microdepressions in a major surface of a web with finely divided powder in which the web is fed continuously to and through a powder filling stage including a driven roller. At the powder filling stage, the powder, which is fed either onto the web upstream of the roller or to the roller of the powder filling stage, is filled into the microdepressions of the web using the driven roller, wherein said roller is rotating about an axis generally transverse to the direction of web, while the surface speed of the roller and the web speed are different and wherein the roller and web are positioned relative to one another, such that between the upper surface of the web and the outer surface of the roller there is a gap. A method of manufacturing an elongate carrier with microdepressions containing finely divided powder comprising steps filling a plurality of microdepressions in a major surface of a web as described, removing from upper surface of the web excess powder not filled within the microdepressions and remaining on areas of the surface between the depressions, and optionally slitting and / or cutting the web in width and / or length.

Owner:ADAMIS PHARMA

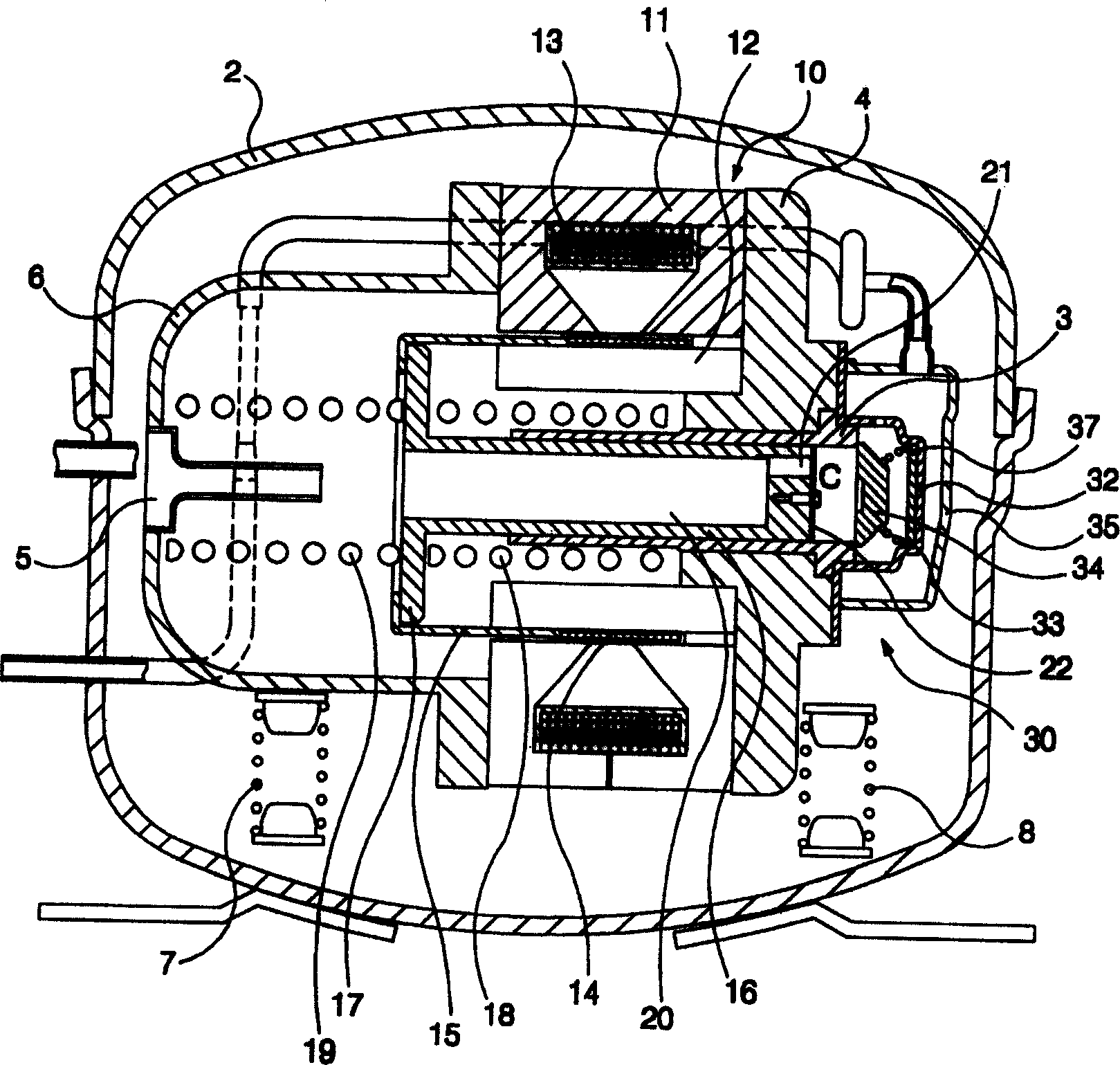

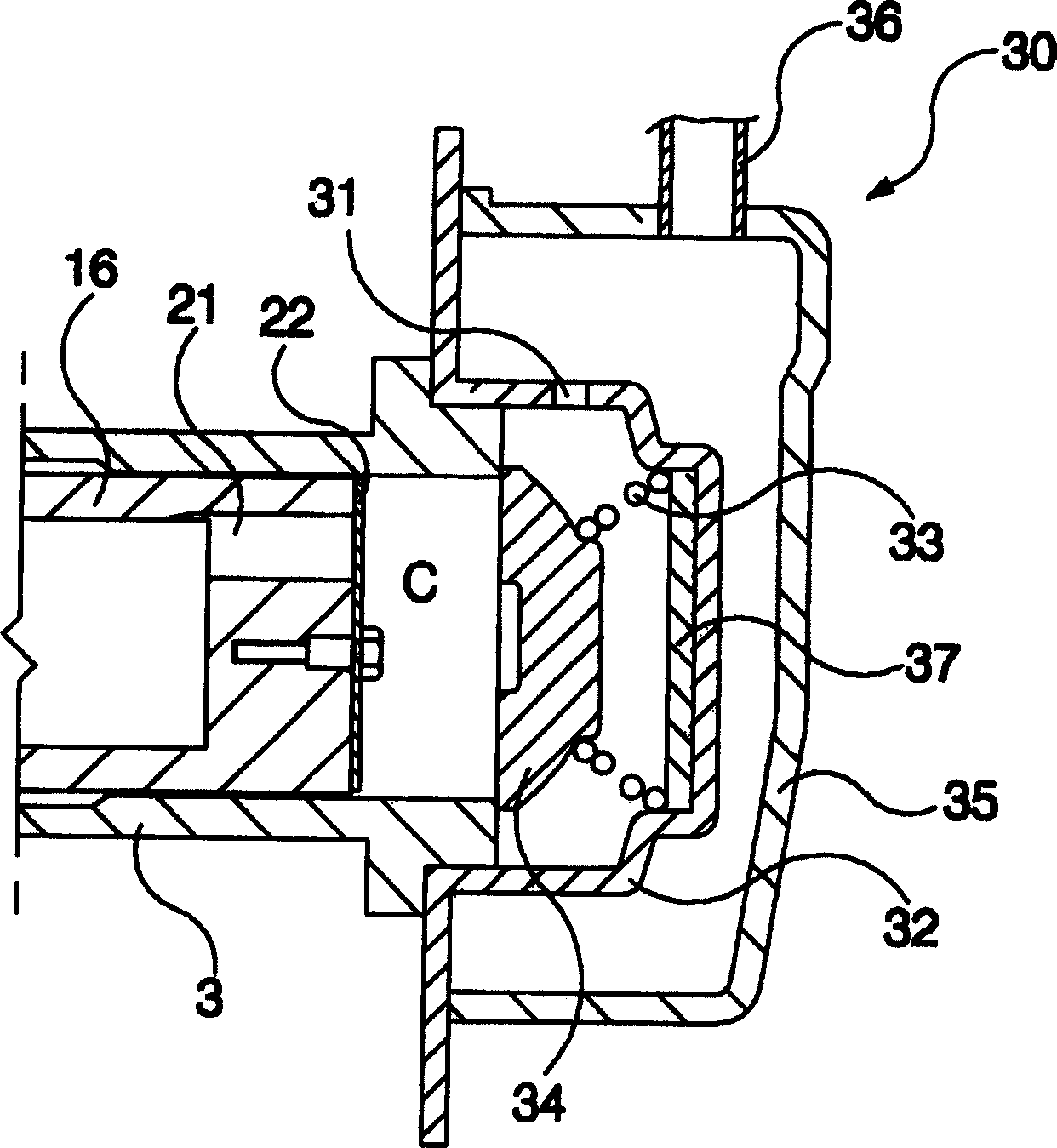

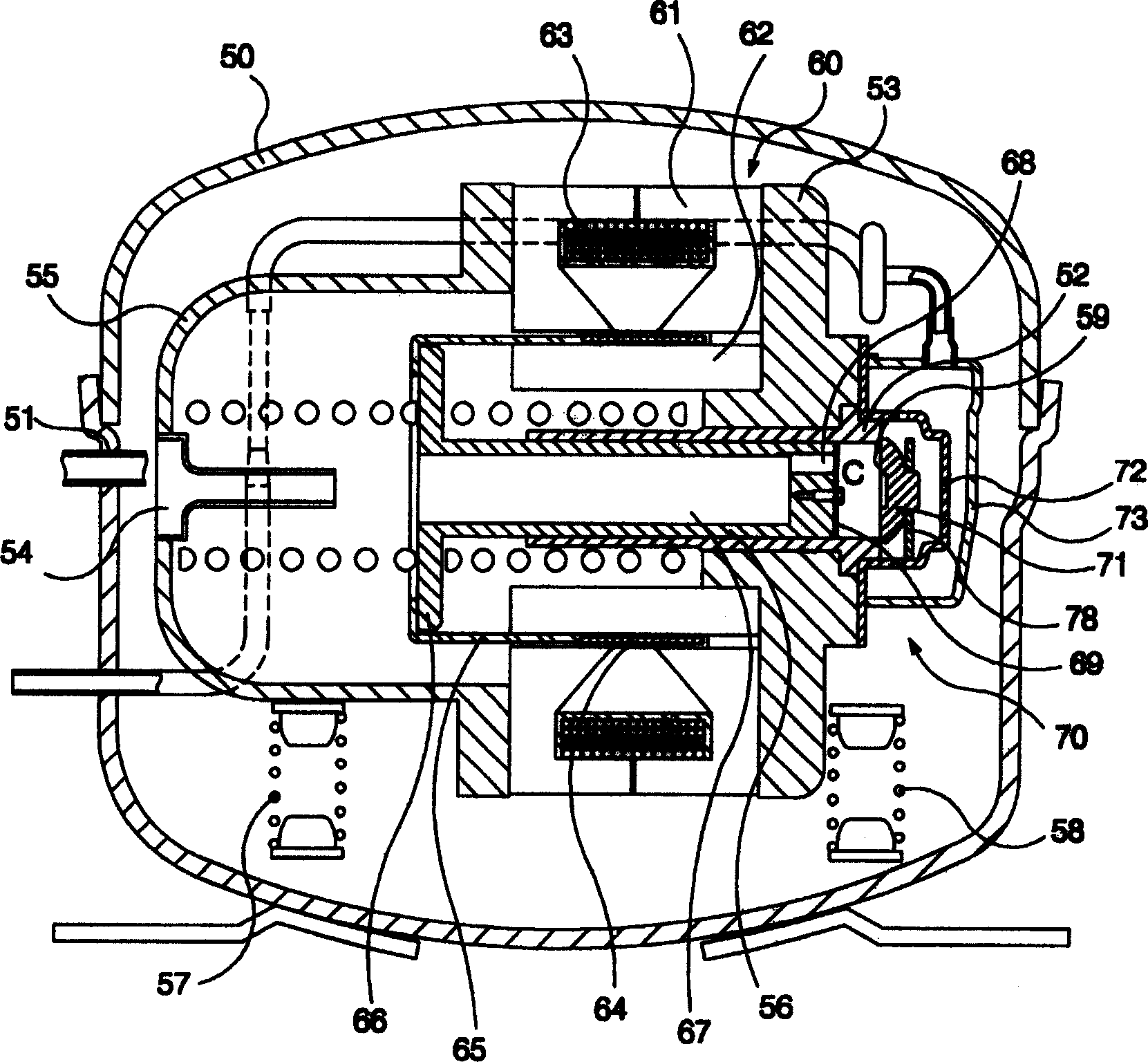

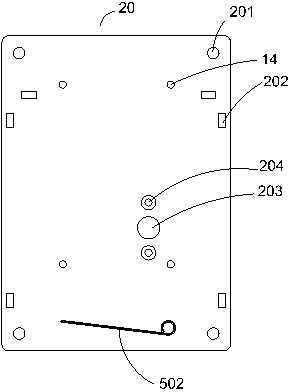

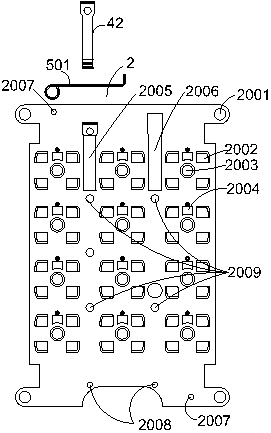

Linear compressor

InactiveCN1757916ACompact structureSmall sizePositive displacement pump componentsLeaf springsLinear compressorLeaf spring

Disclosed herein is a linear compressor. In the present invention, a leaf spring is used for an exhale spring to support an exhale valve. As the leaf spring supports the exhale valve by being bended in a predetermined direction, the exhale valve can be stably opened and closed in the predetermined direction. As a space for the exhale spring becomes reduced in an inner exhale cover, a size of an exhale part is reduced, thus making it possible to produce the compact linear compressor. As the leaf spring is comprised of a plurality of overlapped plates, when the exhale valve is opened and closed, the leaf spring is bended, and friction is generated among the plurality of plates. Therefore, a vibration of the exhale valve is decremented by its friction, thus reducing a friction noise.

Owner:LG ELECTRONICS INC

Powder filling processes

ActiveUS8997799B2Facilitate prevention of formationSome variability in the gap widthRespiratorsPowder deliveryEngineeringMechanical engineering

A method for filling a plurality of microdepressions in a major surface of a web with finely divided powder in which the web is fed continuously to and through a powder filling stage including a driven roller. At the powder filling stage, the powder, which is fed either onto the web upstream of the roller or to the roller of the powder filling stage, is filled into the microdepressions of the web using the driven roller, wherein said roller is rotating about an axis generally transverse to the direction of web, while the surface speed of the roller and the web speed are different and wherein the roller and web are positioned relative to one another, such that between the upper surface of the web and the outer surface of the roller there is a gap. A method of manufacturing an elongate carrier with microdepressions containing finely divided powder comprising steps filling a plurality of microdepressions in a major surface of a web as described, removing from upper surface of the web excess powder not filled within the microdepressions and remaining on areas of the surface between the depressions, and optionally slitting and / or cutting the web in width and / or length.

Owner:ADAMIS PHARMA

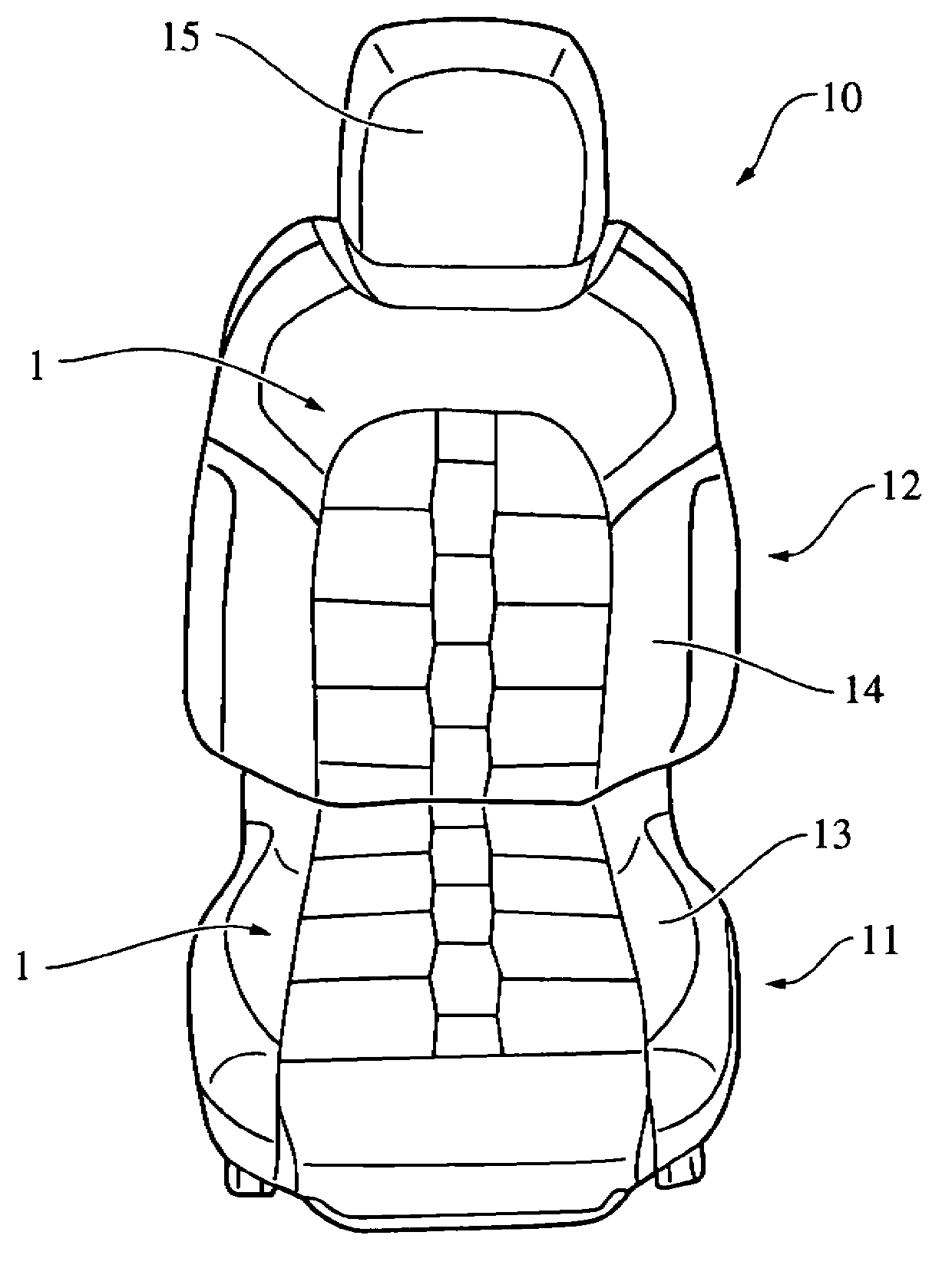

Vehicle seat cover

ActiveCN103108775AStructure simplification/improvementEasy to manufactureUpholstery manufactureSeat coveringsControl theoryMechanical engineering

The invention relates to a vehicle seat cover with an underlay, a cover and an upholstered element which is provided between the cover and the underlay, wherein the underlay, the cover and / or the upholstered element are connected to one another by means of at least one longitudinal seam and at least one transverse seam. Furthermore, the present invention relates to a method for manufacturing a seat cover, and to a vehicle seat having the seat cover according to the invention.

Owner:ADIENT LUXEMBOURG HLDG SARL

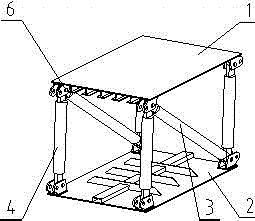

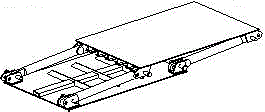

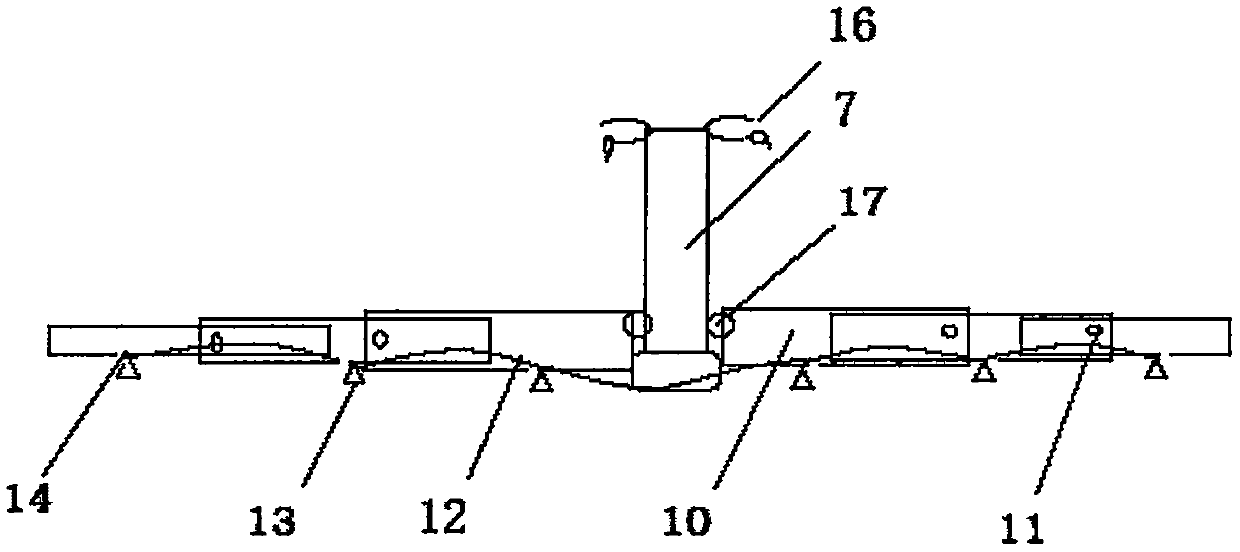

Detachable type modularized emergency bridge

The invention discloses a detachable type modularized emergency bridge. The detachable type modularized emergency bridge comprises a panel, a bottom plate, long connecting rods, vertical rods, long pins, short pins and a transverse connecting rod, wherein an anti-skidding pattern plate is arranged on the upper surface of the panel; a longitudinal reinforcing plate, a transverse partition plate and a connecting lug plate are arranged on the lower surface of the panel; the bottom plate is equipped with the reinforcing rib and the connecting lug plate; the panel, the bottom plate, the four vertical rods and the two long connecting rods form a unit module through eight short pins; the unit modules are assembled into a single spanning bridge through the long pins; the single spanning bridges can be assembled into a bridge span with different bridge widths to meet different passing needs. The detachable type modularized emergency bridge is simple in structure, less in bridge component type, simple to operate, capable of being split into a single component for being transported, also can be folded for being transported through the unit modules after the long connecting rods are detached. The detachable type modularized emergency bridge is suitable for manually splicing and arranging emergency foot bridges for overcoming deep ditches, cracks, rivers and the like during rescuing.

Owner:CHINA HARZONE IND CORP

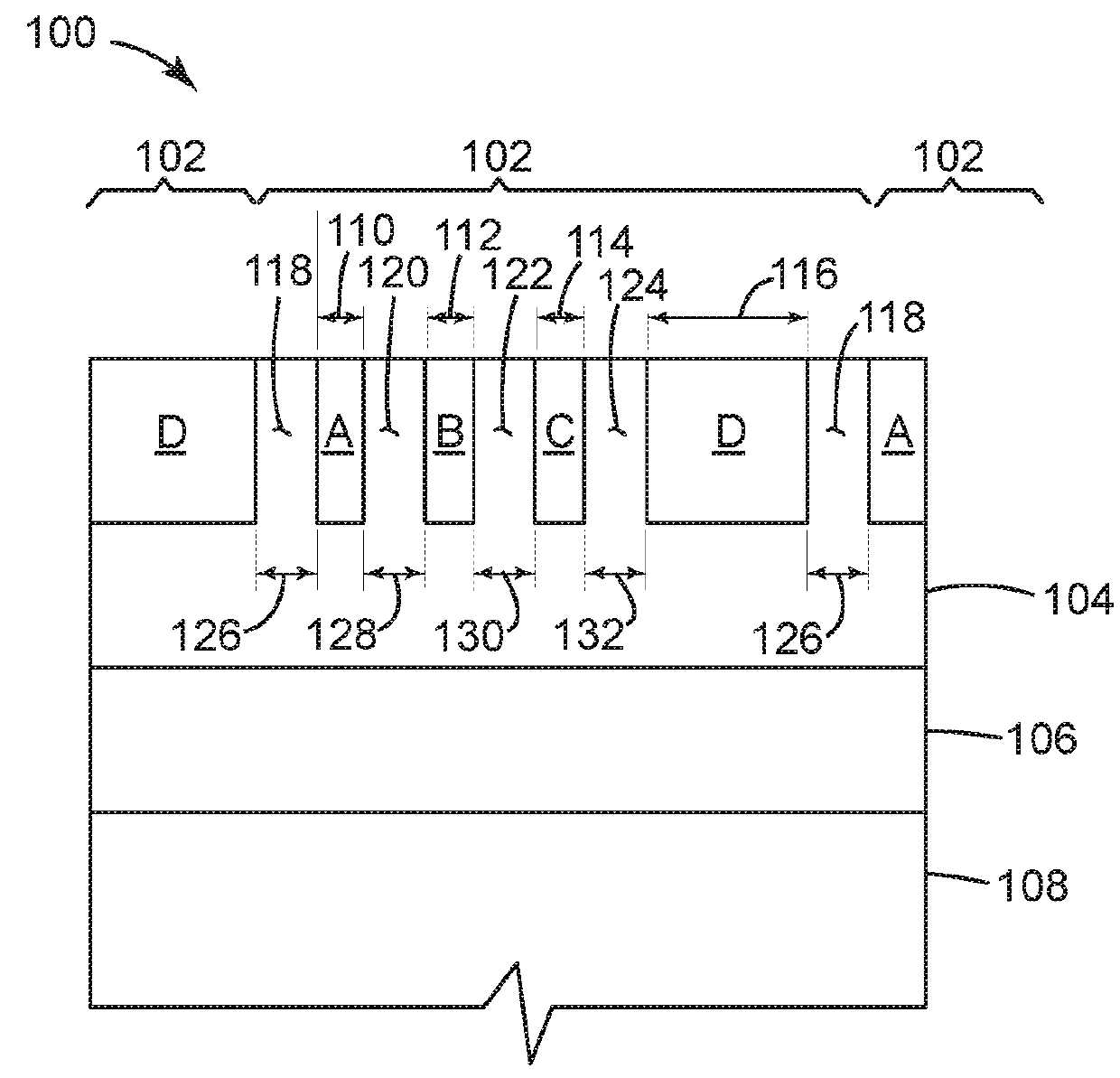

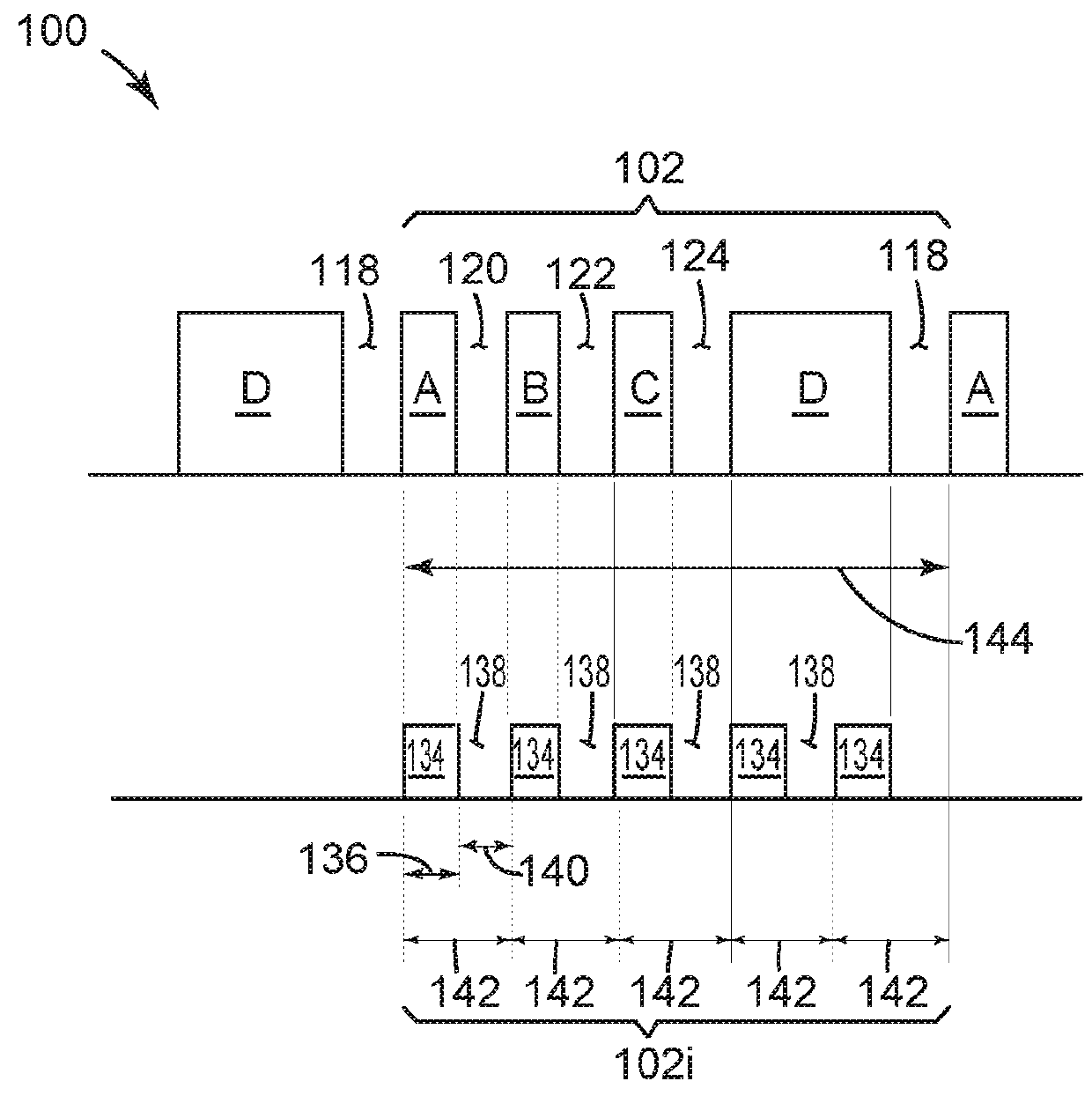

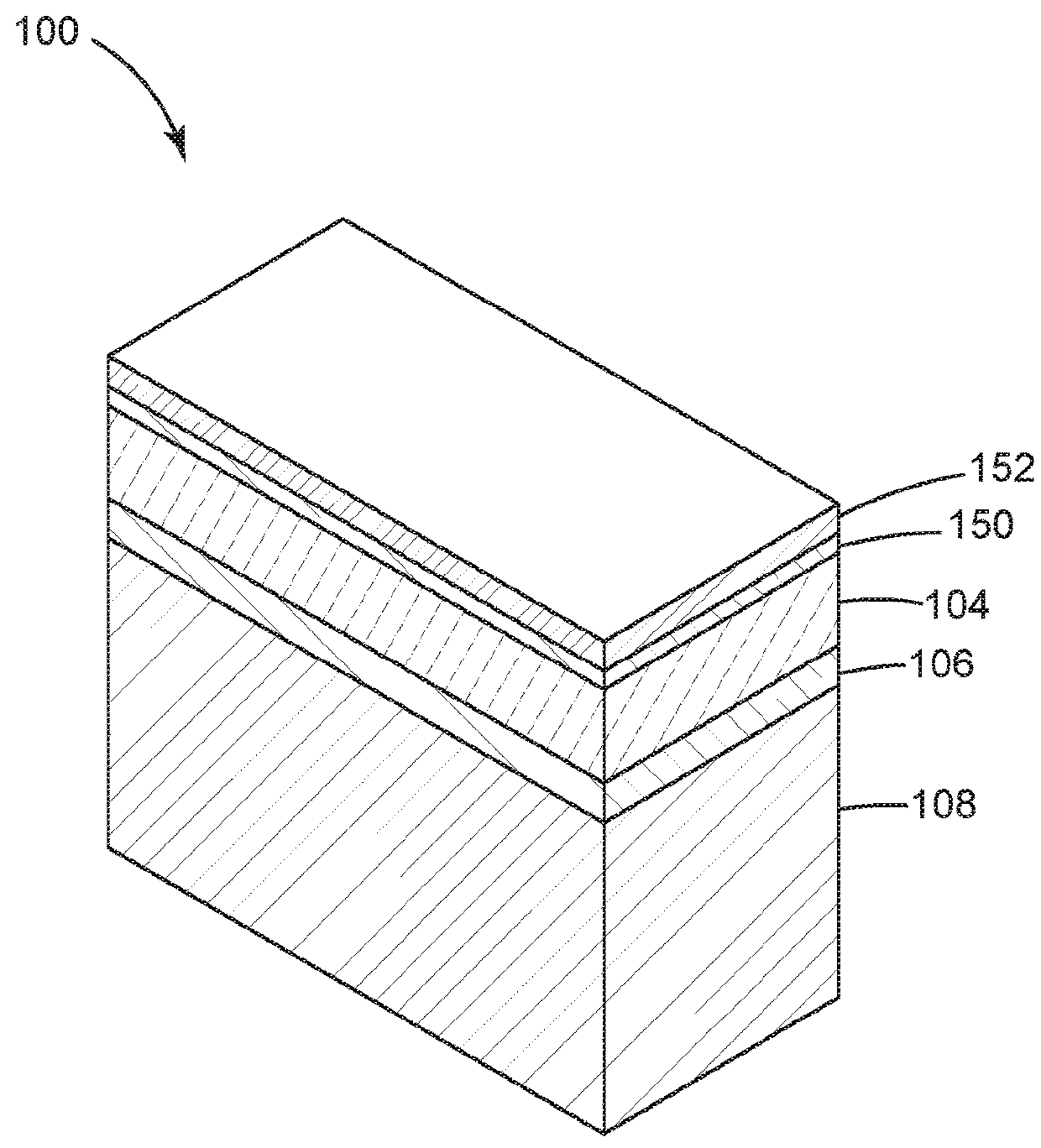

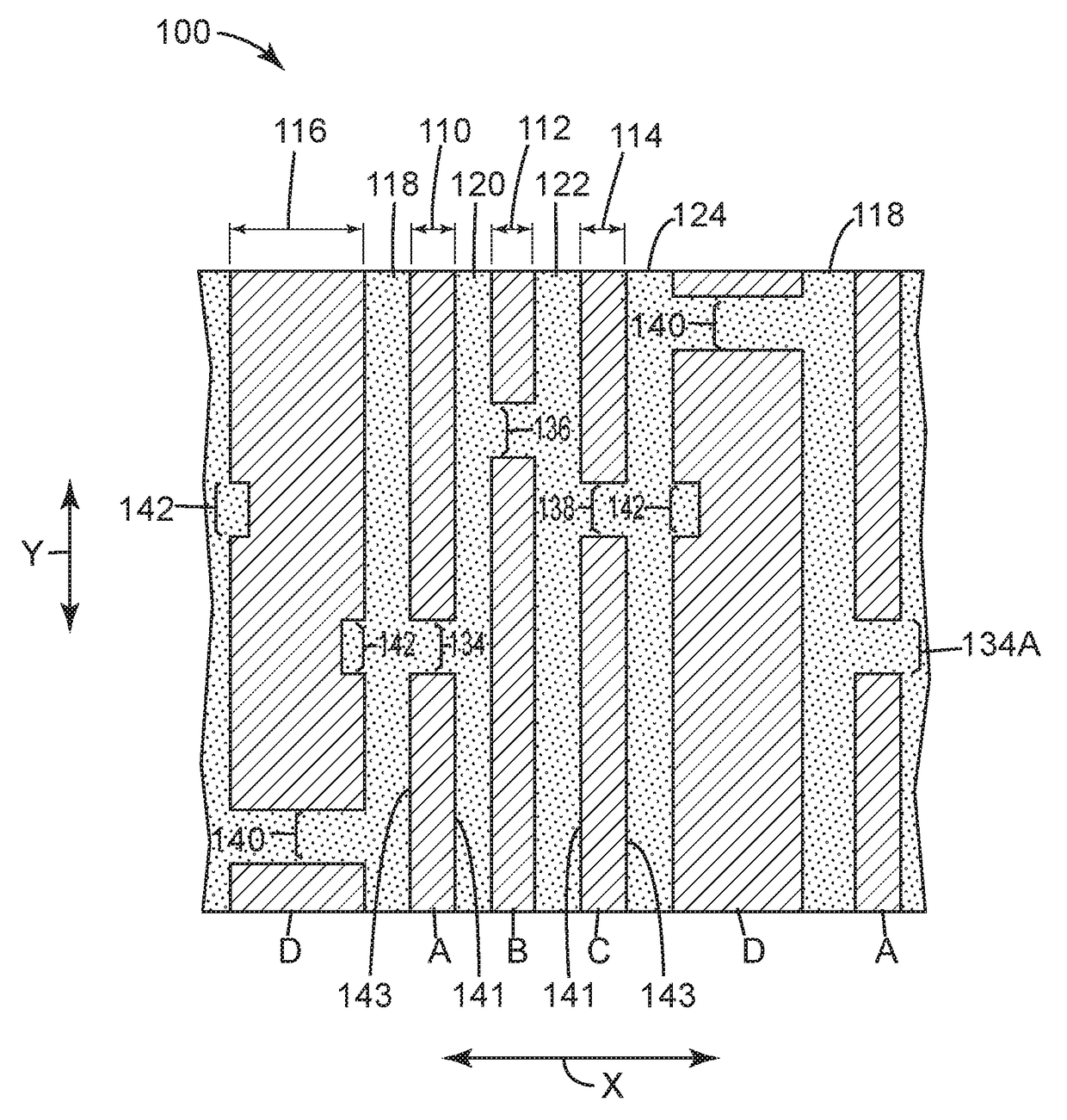

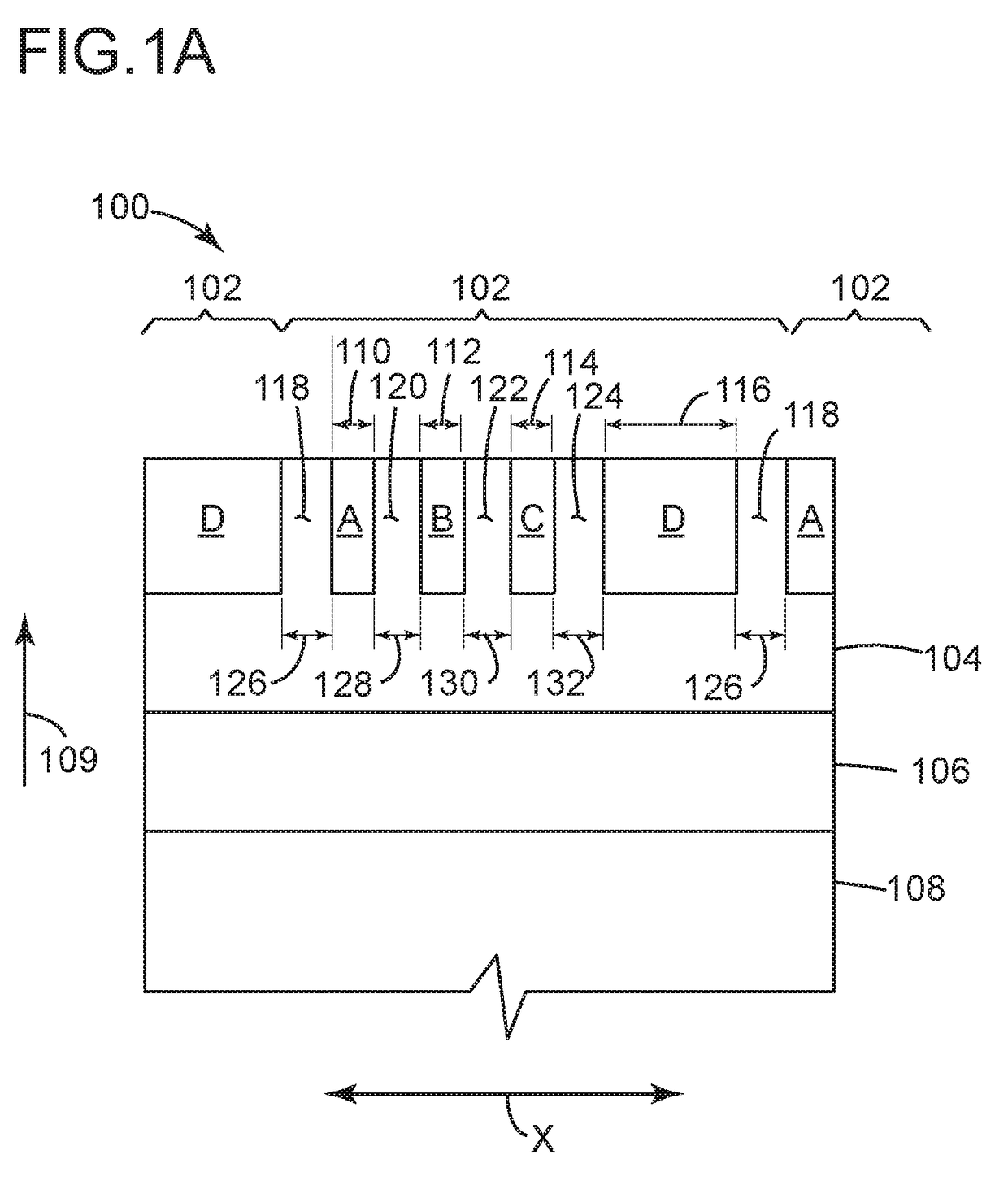

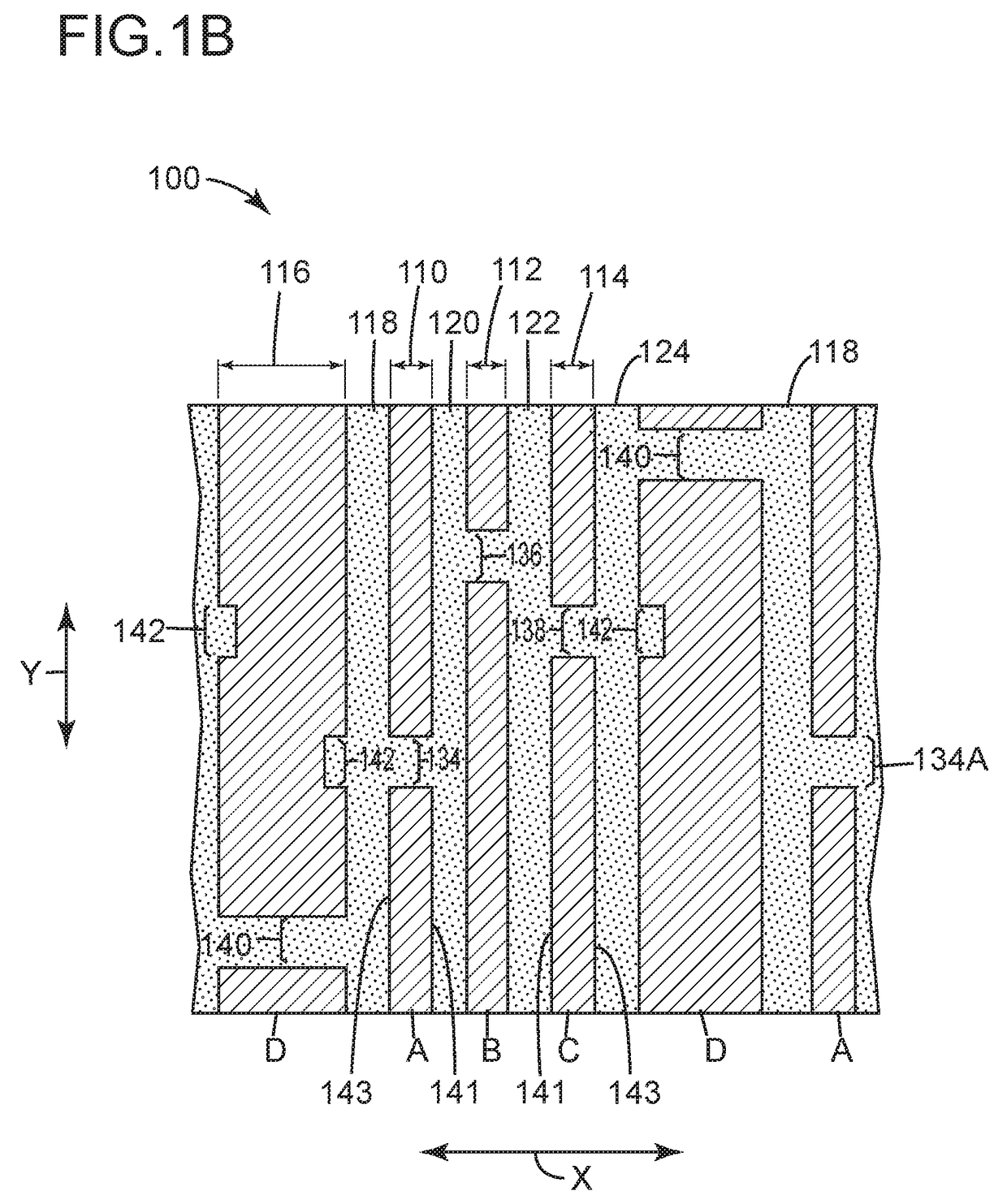

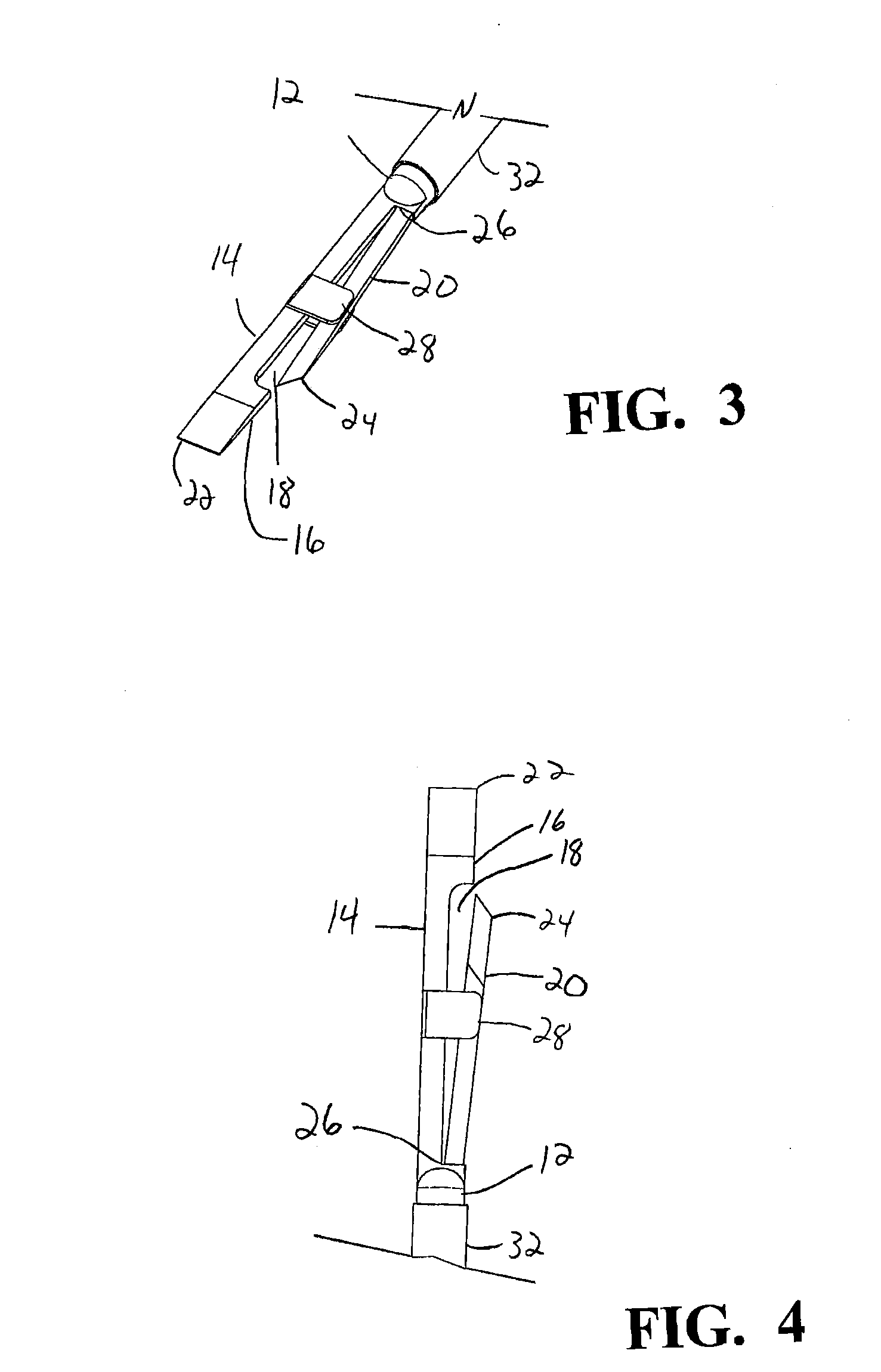

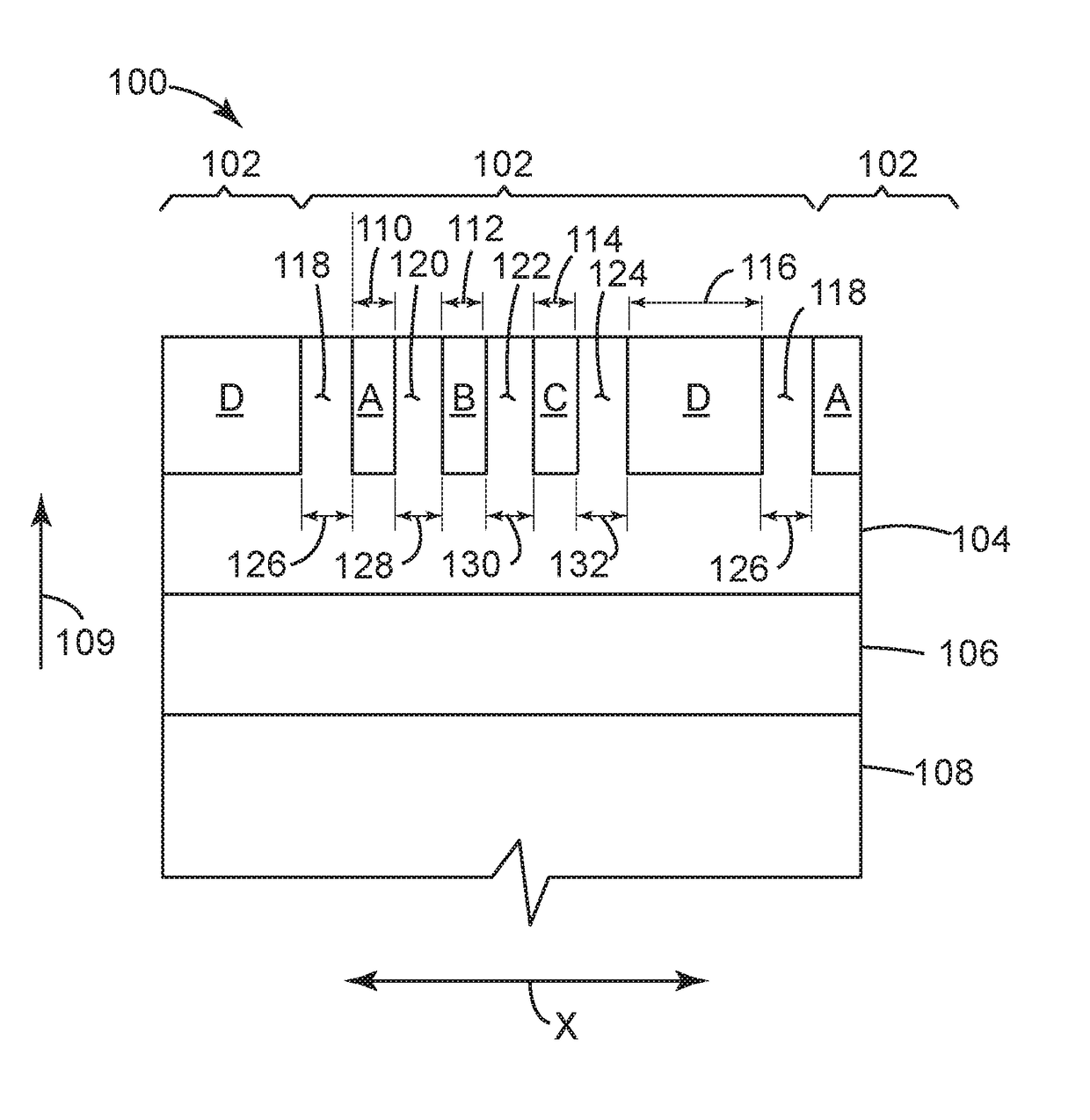

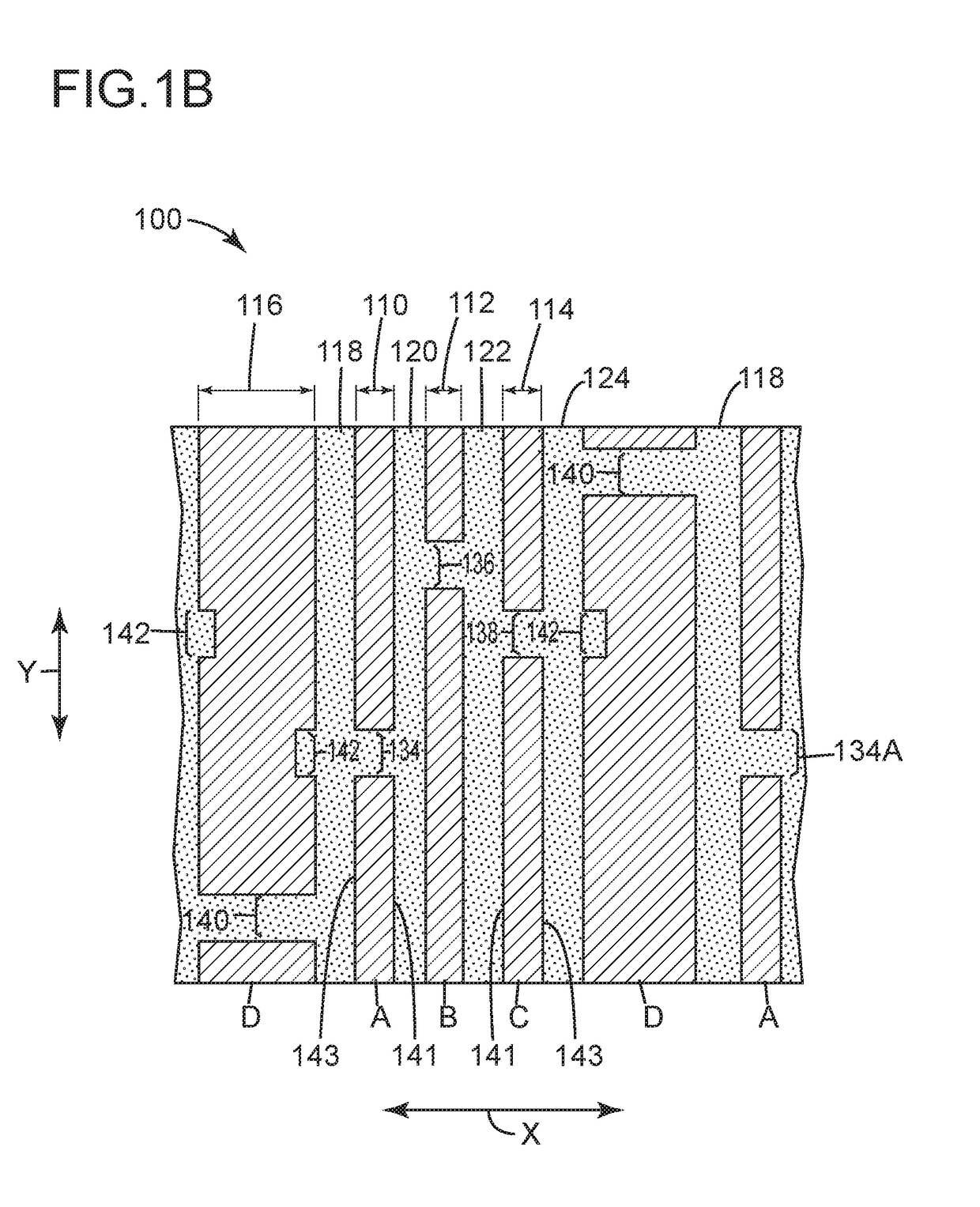

Apparatus and method for forming interconnection lines having variable pitch and variable widths

ActiveUS10043703B2Easy to controlVariable widthSemiconductor/solid-state device detailsSolid-state devicesLine widthInterconnection

A semiconductor cell includes a dielectric layer. An array of at least four parallel metal lines is disposed within the dielectric layer, the metal lines having line widths that are substantially equal to or greater than a predetermined minimum line width. Line spacers are disposed between the metal lines, the line spacers having line spacer widths that are substantially equal to or greater than a predetermined minimum line spacer width. An overall cell height of the cell is substantially equal to an integer multiple of a plurality of cell tracks, each cell track being a minimum pitch of the cell. The minimum pitch being defined by the minimum line width plus the minimum line spacer width. The minimum pitch is equal to or less than 36 nm. Not all of the line widths are substantially equal and every other line spacer width is substantially equal.

Owner:GLOBALFOUNDRIES US INC

Interconnection lines having variable widths and partially self-aligned continuity cuts

ActiveUS9887127B1Easy to controlVariable widthSemiconductor/solid-state device detailsSolid-state devicesEngineeringInterconnection

A semiconductor cell includes a dielectric layer. An array of parallel metal lines is disposed in a longitudinal direction within the dielectric layer. The metal lines having line widths that are substantially equal to or greater than a predetermined minimum line width. Line spacers are disposed between the metal lines. The line spacers having line spacer widths that are substantially equal to or greater than a predetermined minimum line spacer width. The array of metal lines includes a signal line having a continuity cut disposed across its entire line width and a power line adjacent the signal line. The power line has a line width that is greater than twice the minimum line width. The power line has a notch disposed partially across its line width. The notch is aligned with the continuity cut in a direction perpendicular to the longitudinal direction of the metal lines.

Owner:GLOBALFOUNDRIES US INC

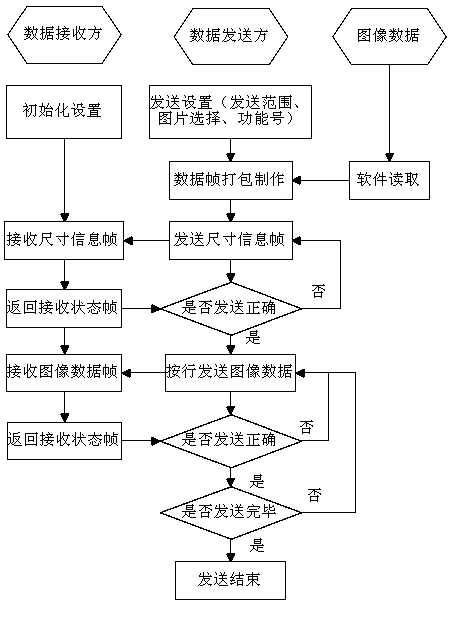

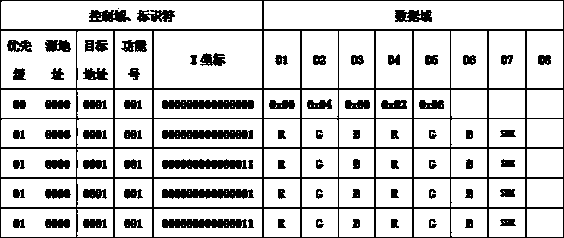

Reliable image data transmission method based on CAN bus

InactiveCN104270550AIncrease transfer rateImprove transmission reliabilityTransmissionPictoral communicationComputer hardwareData integrity

The invention discloses a reliable image data transmission method based on a CAN bus. The method is based on a CAN expansion frame format and conducts dynamic secondary division based on row data, sequence matching, consistency checkout, error handling and the like on the image data blocks transmitted on the CAN bus so that transmission reliability can be improved, and data integrity can be guaranteed. By means of the method, the image data with the transmission height being 65536 pixels and the width being 65536 pixels can be transmitted at most, and great help is provided for expanding application of the CAN bus.

Owner:HUBEI UNIV OF TECH

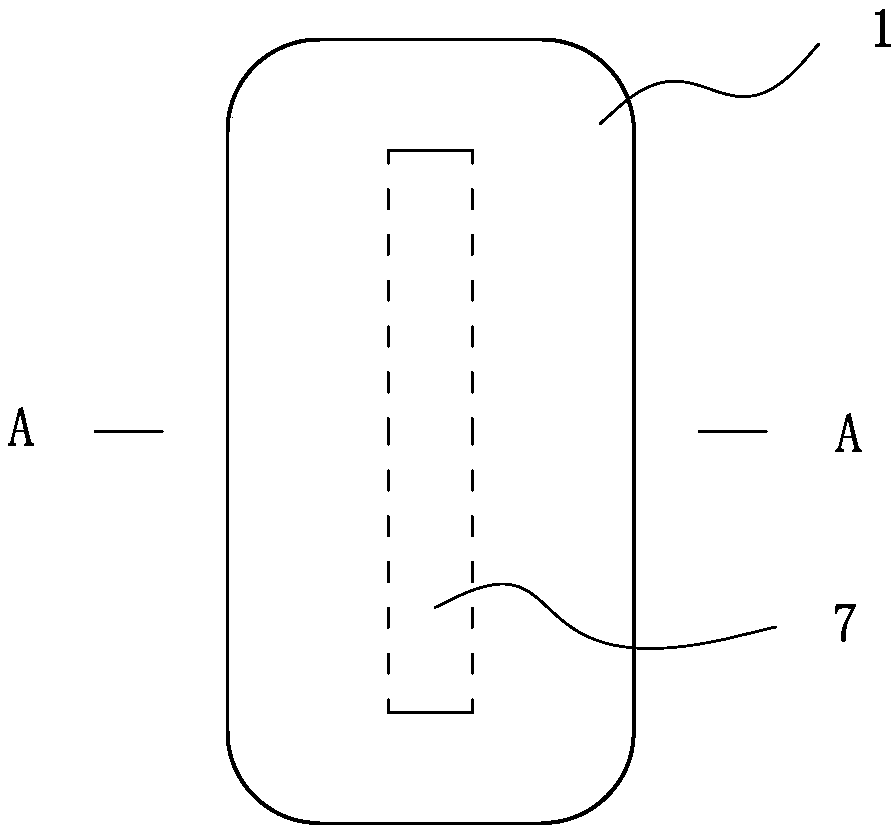

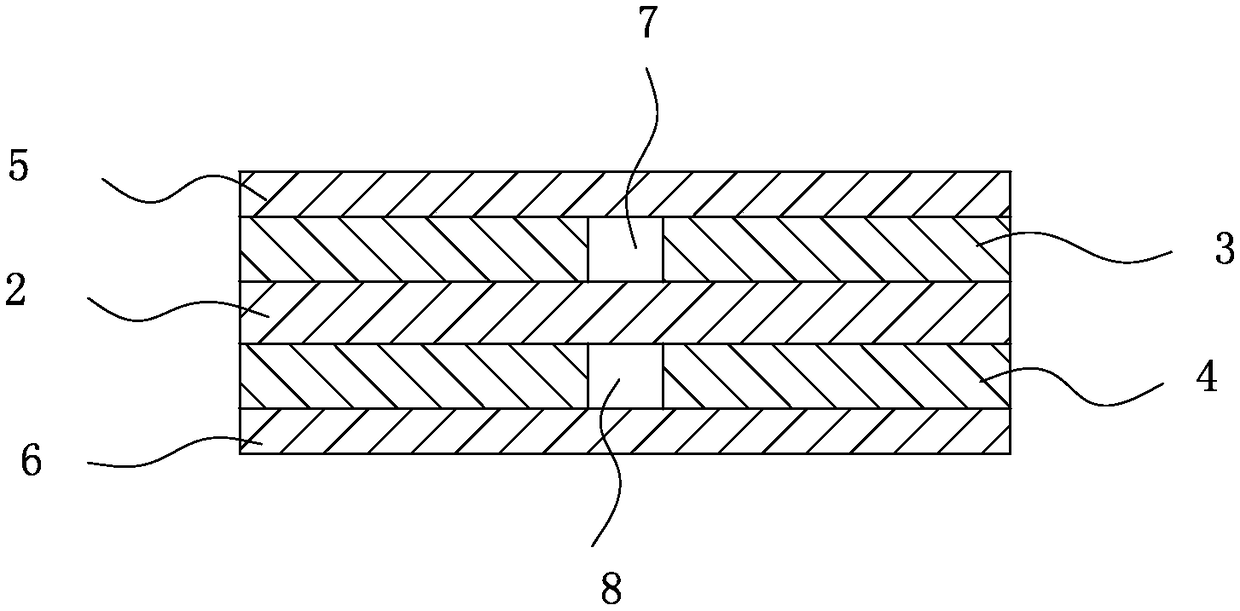

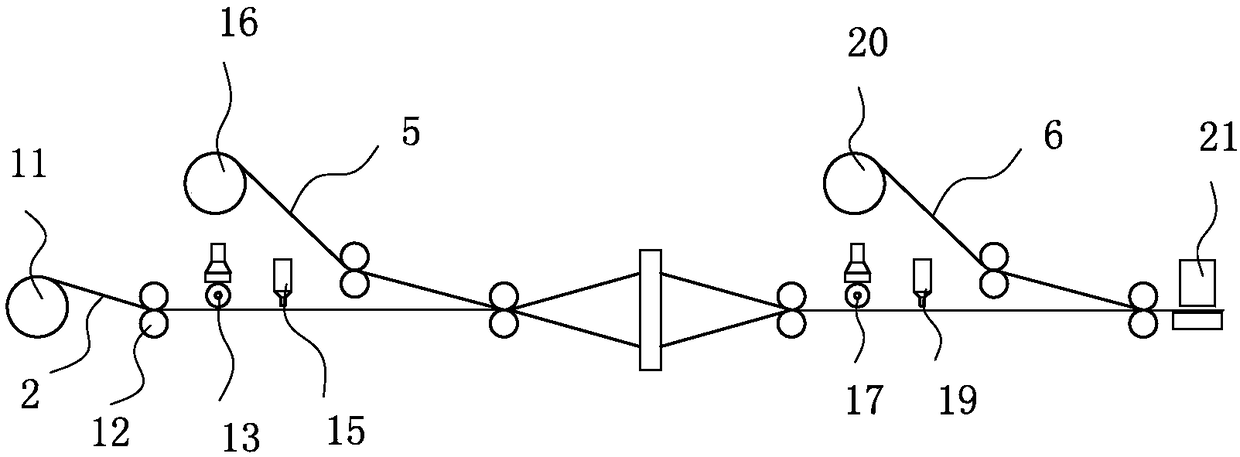

Fast-infiltration breathable absorption object and preparation method thereof

InactiveCN108309578APromote absorptionImprove absorption ratePersonal careLaminationNonwoven fabricPlant sap

The invention relates to the field of disposable sanitary products, in particular to a fast-infiltration breathable absorption object and a preparation method thereof, and mainly solves the problems that an absorption object in the prior art is slow in infiltration and poor in breathability. The fast-infiltration breathable absorption object comprises an absorption core and is characterized in that the absorption core comprises bulky nonwoven fabric, a first sap layer and a second sap layer are respectively arranged on the upper surface and the lower surface of the bulky nonwoven fabric, firstdust-free paper is compositely adhered to the first sap layer, second dust-free paper is compositely adhered to the second sap layer, the first sap layer is provided with at least one first through groove, the second sap layer is provided with at least one second through groove, and the width of each first through groove and each second through groove is 0.1-40mm.

Owner:美佳爽(中国)有限公司

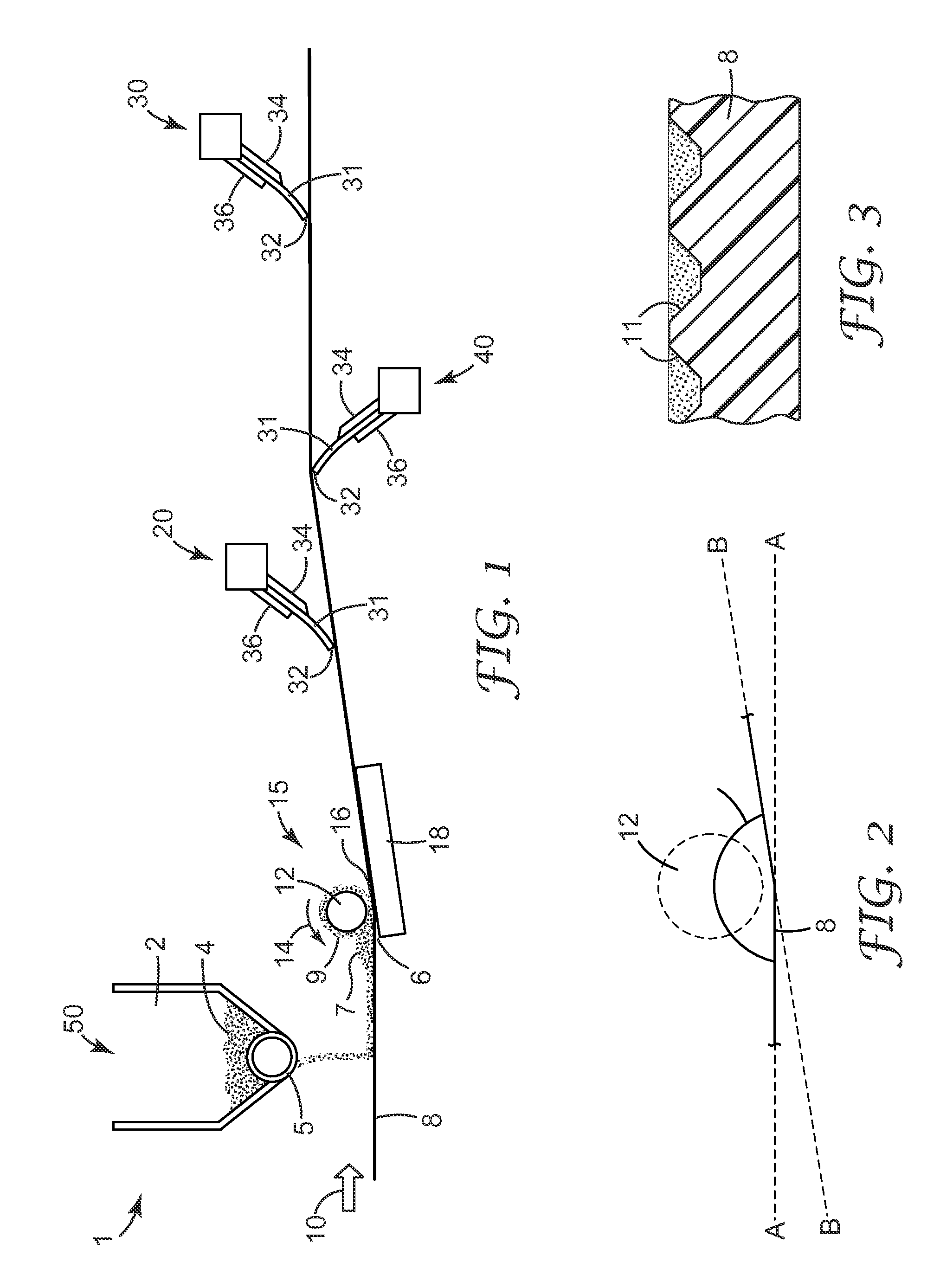

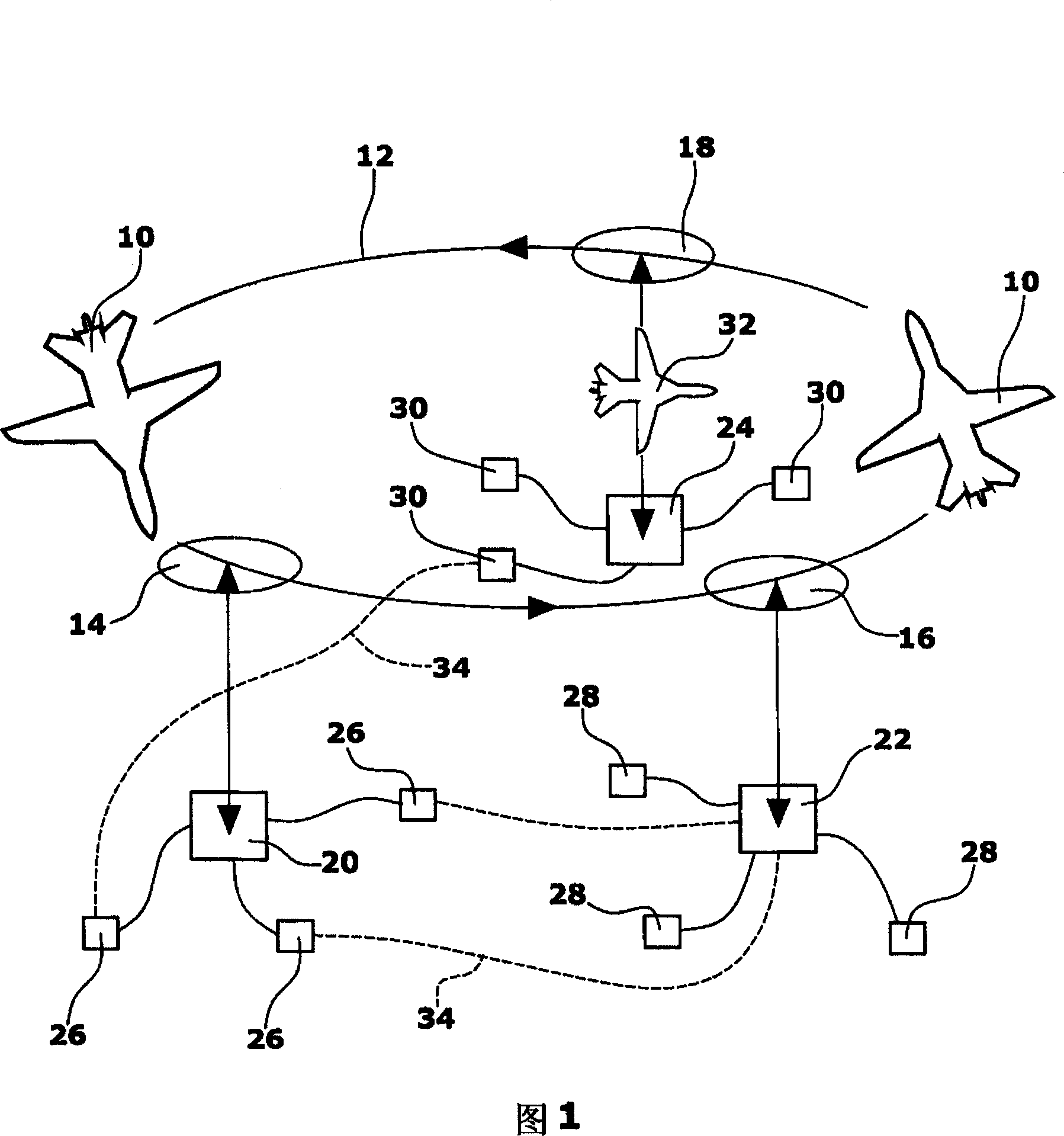

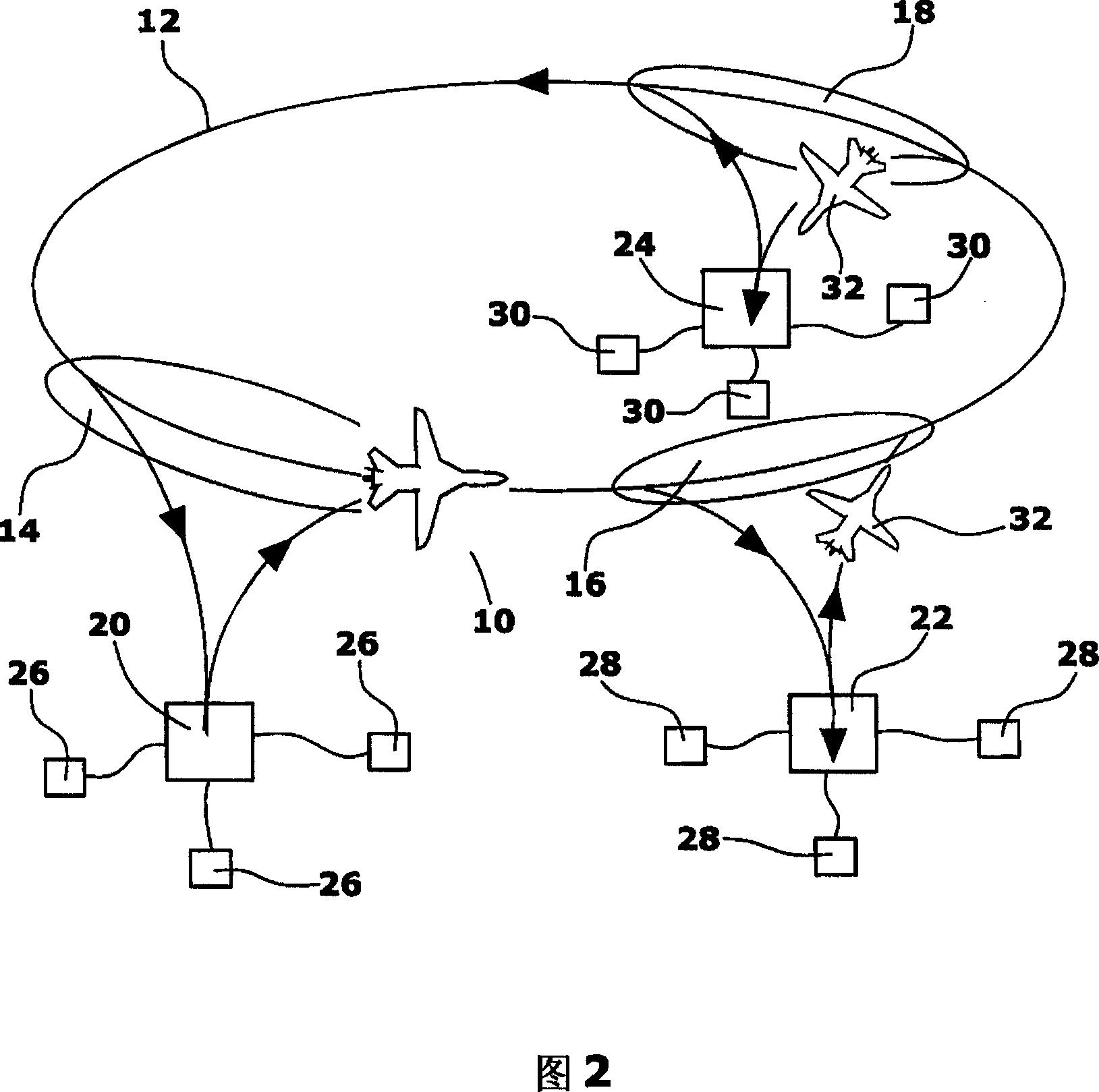

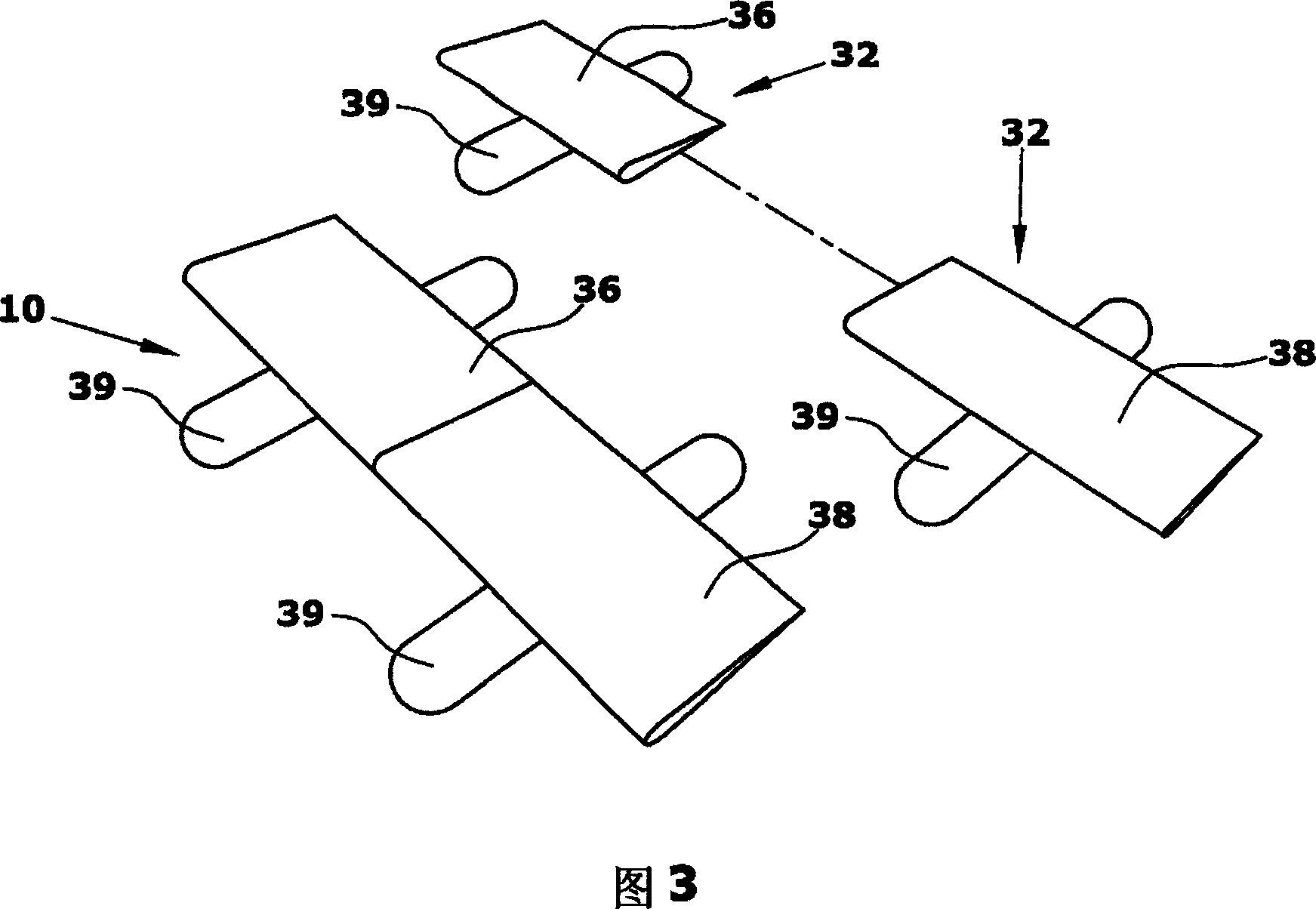

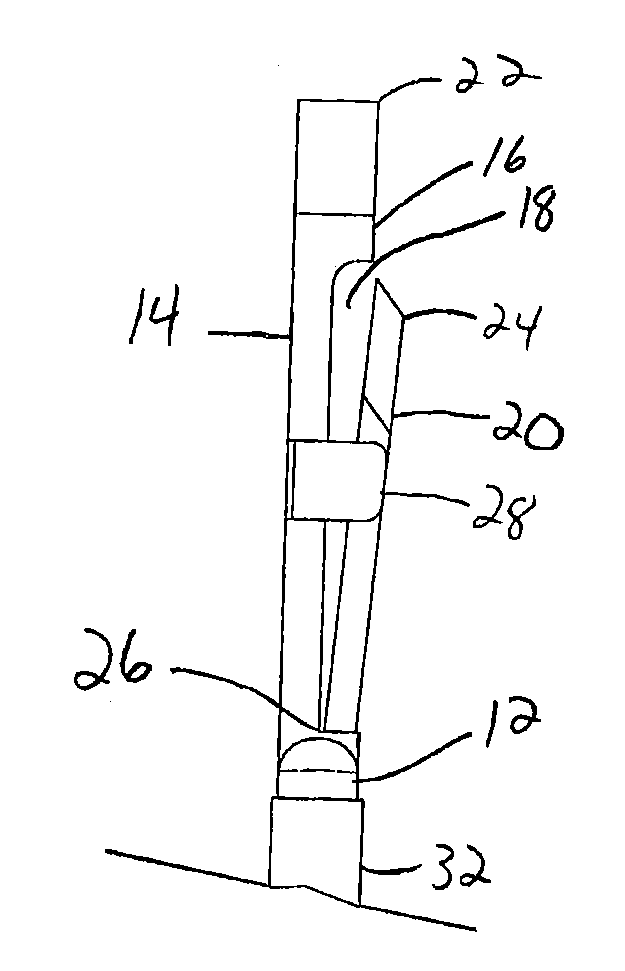

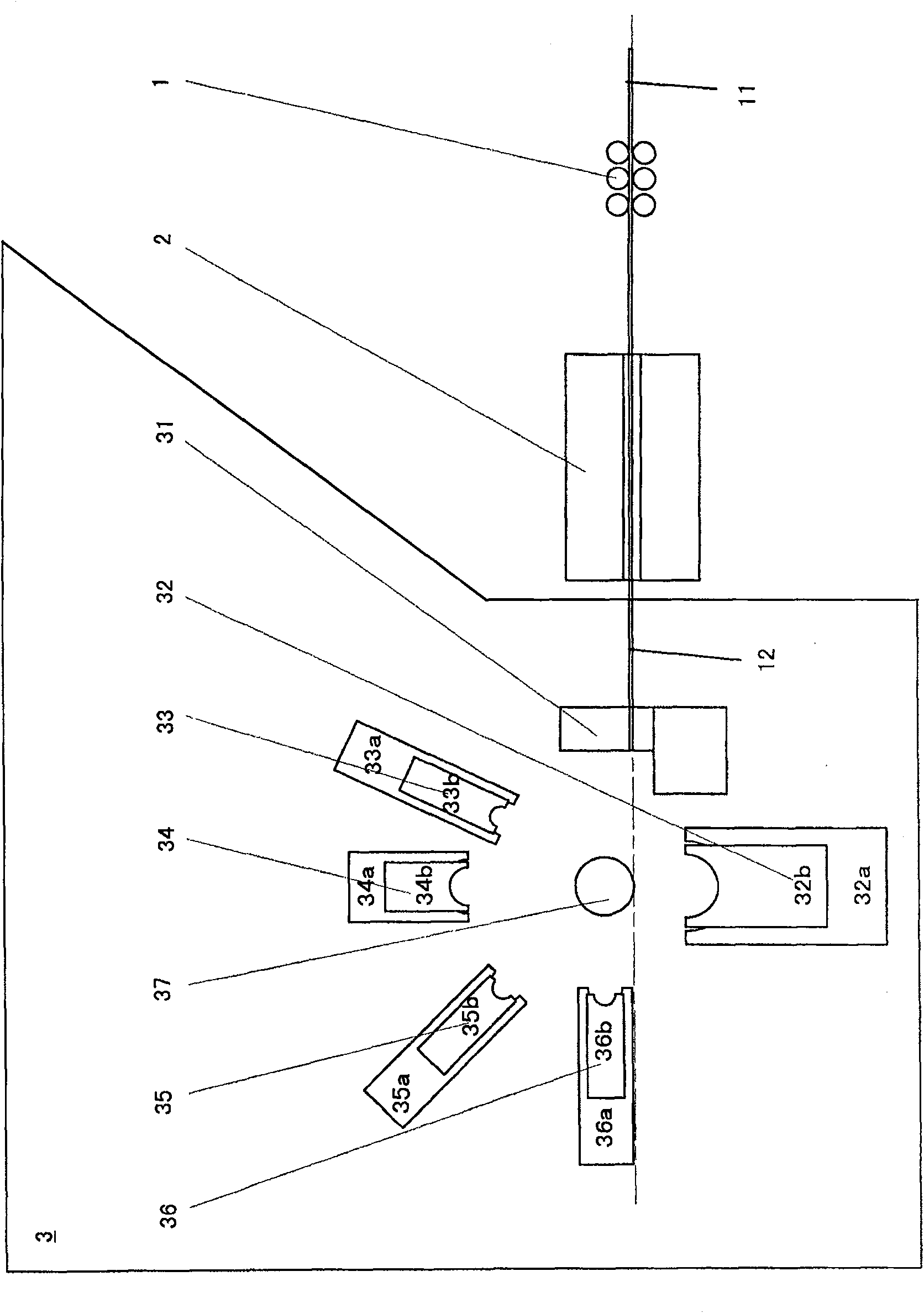

Air freight transport method, transport aeroplane and air freight transport system

InactiveCN1960910AExtended use timeImprove transportation efficiencyConvertible aircraftsFreight handlingTransport systemAir freight

The invention relates to an air freight transport system which is used to transport various freights to different destinations (26, 28, 30). According to the invention, a transport aeroplane (10), which crosses through at least three air zones (14, 16, 18) associated with one station (20, 22, 24), is prepared. The aeroplane can not land on one of the stations (20, 22, 24). Transportation of the freight between the transport aeroplane (10) and one of the stations (20, 22, 24) occurs with the help of feeder planes (32), whereby transfer of the freight between the feeder plane (32) and the transport plane (10) takes place in the air. The transport plane (10) and two feeder planes (32) form the inventive air freight transport system and the transport aeroplane (10) can comprise two feeder planes (32) which are connected together. The inventive air freight transport method improves the charge of the transport aeroplanes (10). Additionally, the transport paths for individual freights can be shortened thus making said method more economical.

Owner:加比·特劳特·赖因哈特

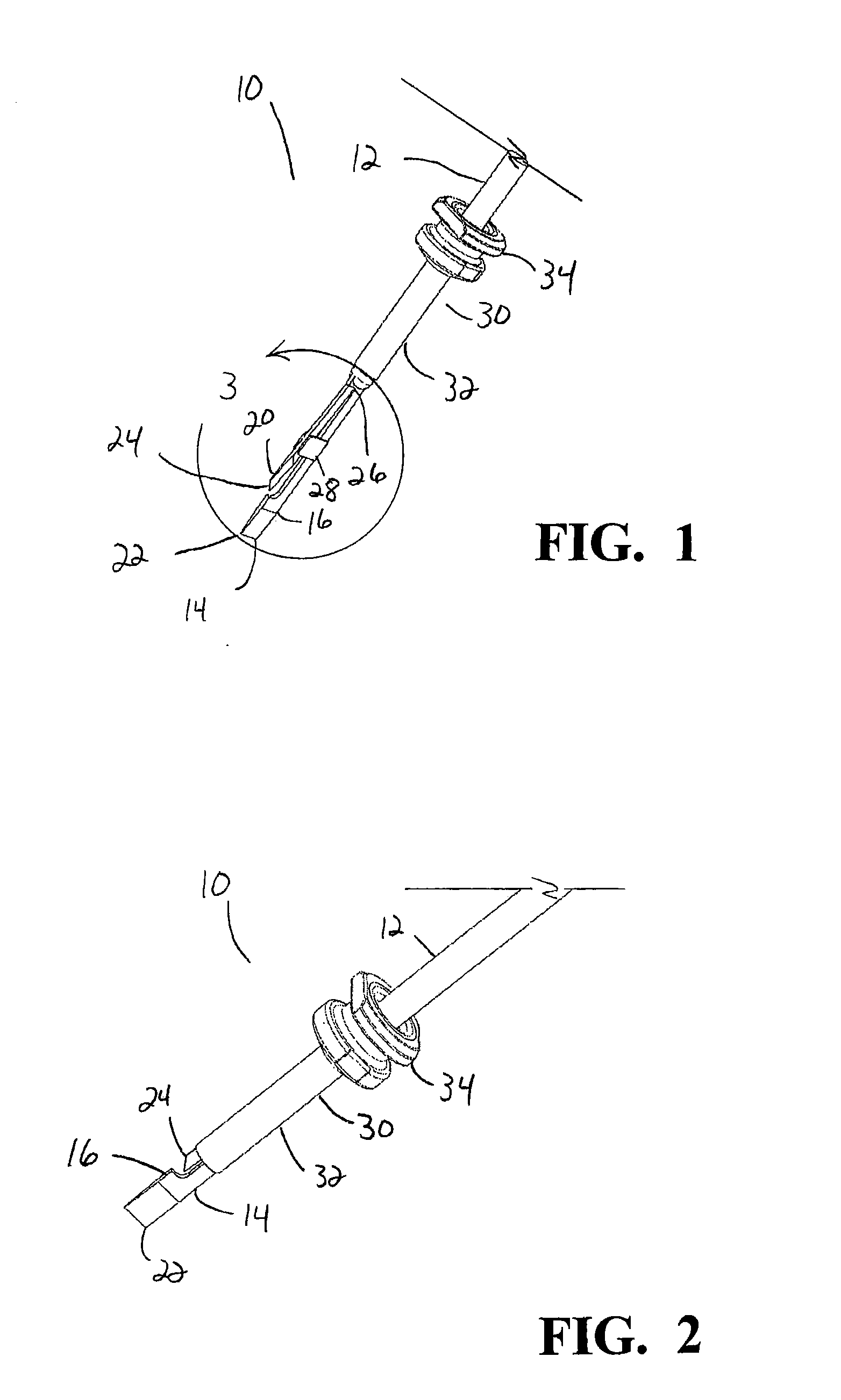

Adjustable Width Trocar

InactiveUS20090182367A1Variable widthIncision instrumentsEye surgeryEngineeringMechanical engineering

Owner:ALCON RES LTD

Interconnection lines having variable widths and partially self-aligned continuity cuts

InactiveUS20180174896A1Easy to controlVariable widthSemiconductor/solid-state device detailsSolid-state devicesInterconnectionMechanical engineering

A semiconductor cell includes a dielectric layer. An array of parallel metal lines is disposed in a longitudinal direction within the dielectric layer. The metal lines having line widths that are substantially equal to or greater than a predetermined minimum line width. Line spacers are disposed between the metal lines. The line spacers having line spacer widths that are substantially equal to or greater than a predetermined minimum line spacer width. The array of metal lines includes a signal line having a continuity cut disposed across its entire line width and a power line adjacent the signal line. The power line has a line width that is greater than twice the minimum line width. The power line has a notch disposed partially across its line width. The notch is aligned with the continuity cut in a direction perpendicular to the longitudinal direction of the metal lines.

Owner:GLOBALFOUNDRIES U S INC

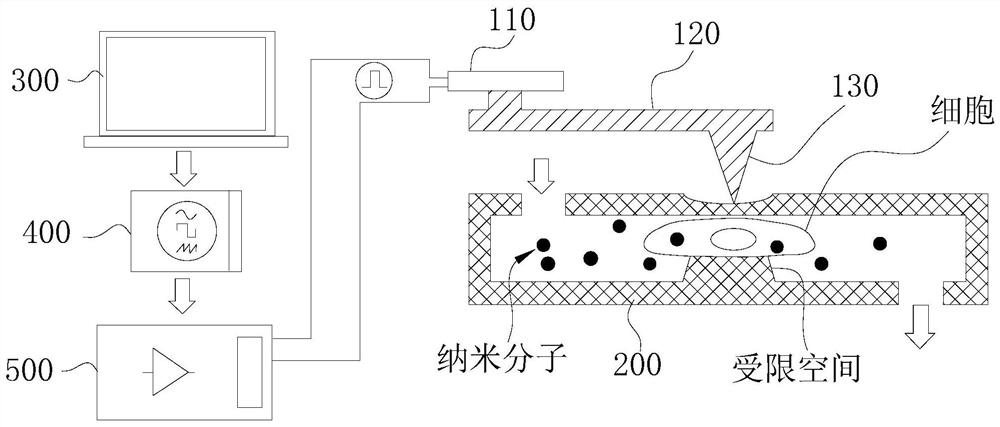

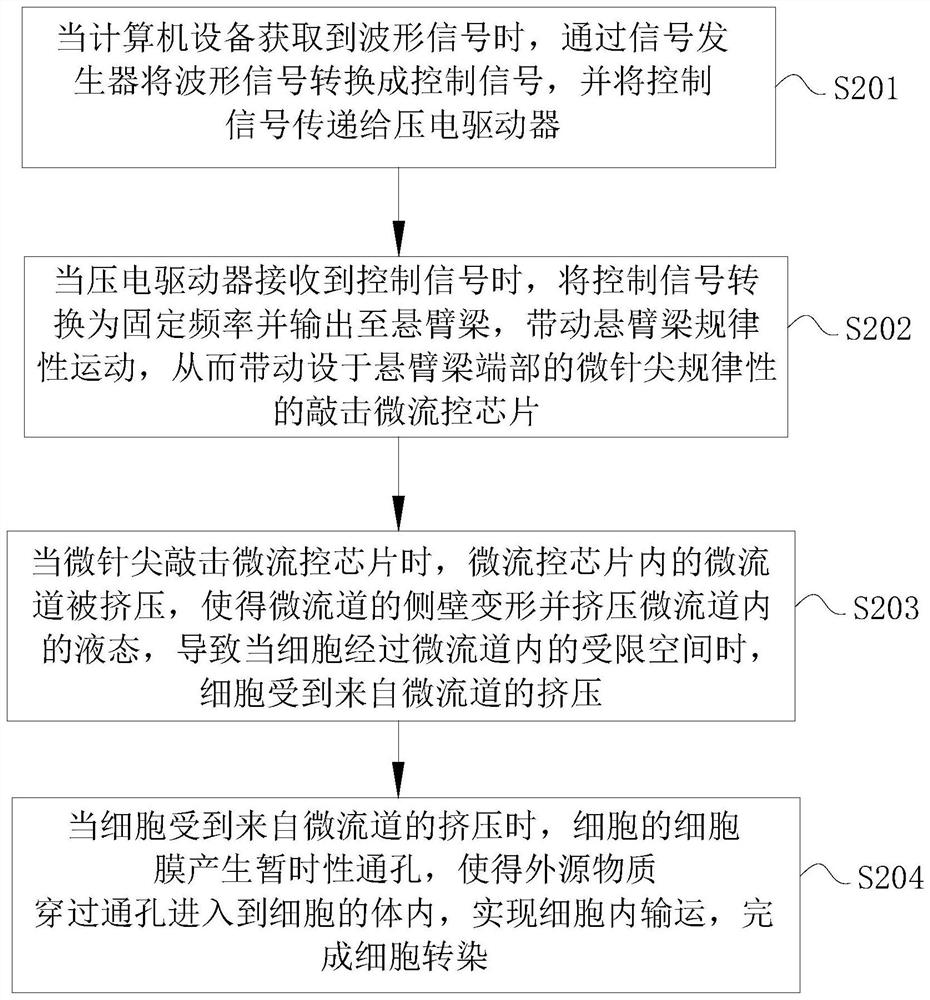

Cell transfection device, cell transfection method and micro-channel manufacturing method

ActiveCN113817589ASolve the problem of low transfection efficiencyVariable widthBioreactor/fermenter combinationsBiological substance pretreatmentsPiezoelectric actuatorsEngineering

The invention provides a cell transfection device, a cell transfection method and a micro-channel manufacturing method. The cell transfection device comprises a micro-fluidic chip and a tunable extrusion mechanism, a micro-channel is arranged in the micro-fluidic chip, a limited space is arranged in the micro-channel, and a plurality of allogenic materials are arranged in the micro-channel; the tunable extrusion mechanism comprises a micro needle tip, a piezoelectric actuator and a cantilever beam; and when the piezoelectric actuator vibrates, the micro needle tip is driven to move up and down, extrudes or is separated from the micro-fluidic chip, cell membranes of cells in the limited space are driven to be damaged to generate through holes, and the allogenic materials enter the cells through the through holes. According to the cell transfection device, the cell transfection method and the micro-channel manufacturing method, the micro-fluidic chip is regularly extruded or separated through the tunable extrusion mechanism, so that the width of the micro-channel is variable, the micro-channel is suitable for cells with different sizes, and the problem that a traditional micro-channel with a fixed width is only suitable for cells with specific sizes or deformation force and has low transfection efficiency on macromolecular nano allogenic materials is solved.

Owner:NANCHANG UNIV

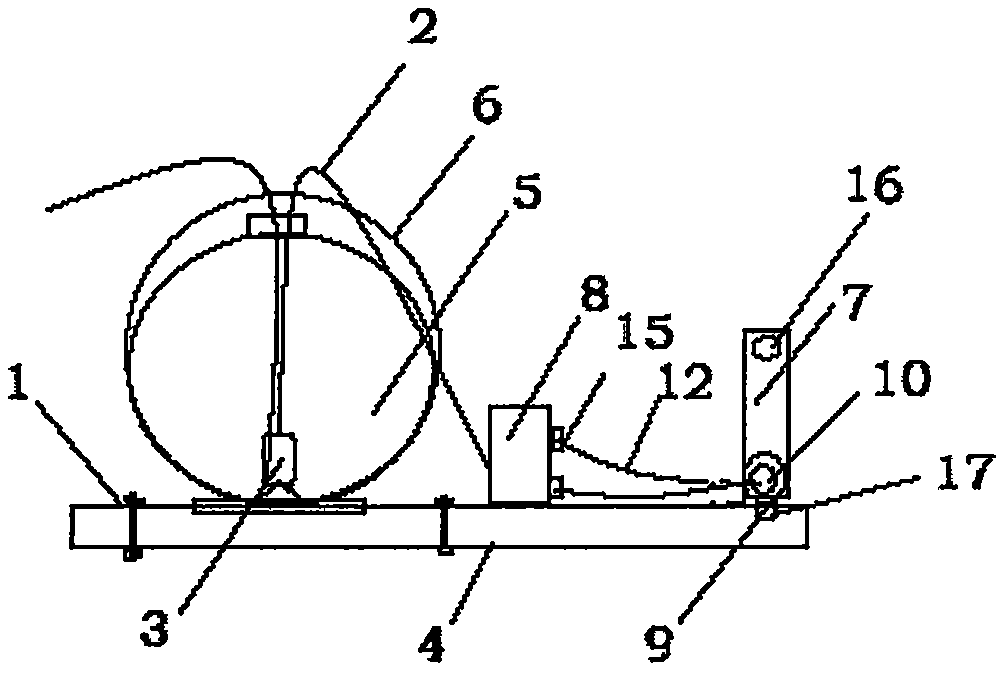

Design method for spraying machine

The invention discloses a design method for a spraying machine. The spraying machine is characterized by variable wings, horizontal and vertical dual use and adjustable width and height. The sprayingmachine comprises a detachable frame; the spraying machine is characterized in that a capsule, a diving spraying pump and a spraying rack are arranged on the detachable frame; a chassis is arranged onthe detachable frame; a support frame for capsule is assembled on the chassis; the support frame for capsule is of rebar barrel shape; the diving spraying pump is built in the capsule; a liquor splitter and a horizontal and vertical guide platform are arranged on the detachable frame. The spraying machine is suitable for spraying herbicide into cornfields and spraying insecticide onto roadside trees. The spraying machine has the beneficial effects: 1) detachability and easiness in storage after use; 2) multifunction and suitability for agriculture and forestry; 3) variable horizontal sprayingwidth, few and collapsible ridges, capability of spraying roadside trees and vertically walking on road, and easiness in carrying home after the completion of work.

Owner:SICHUAN AGRI UNIV

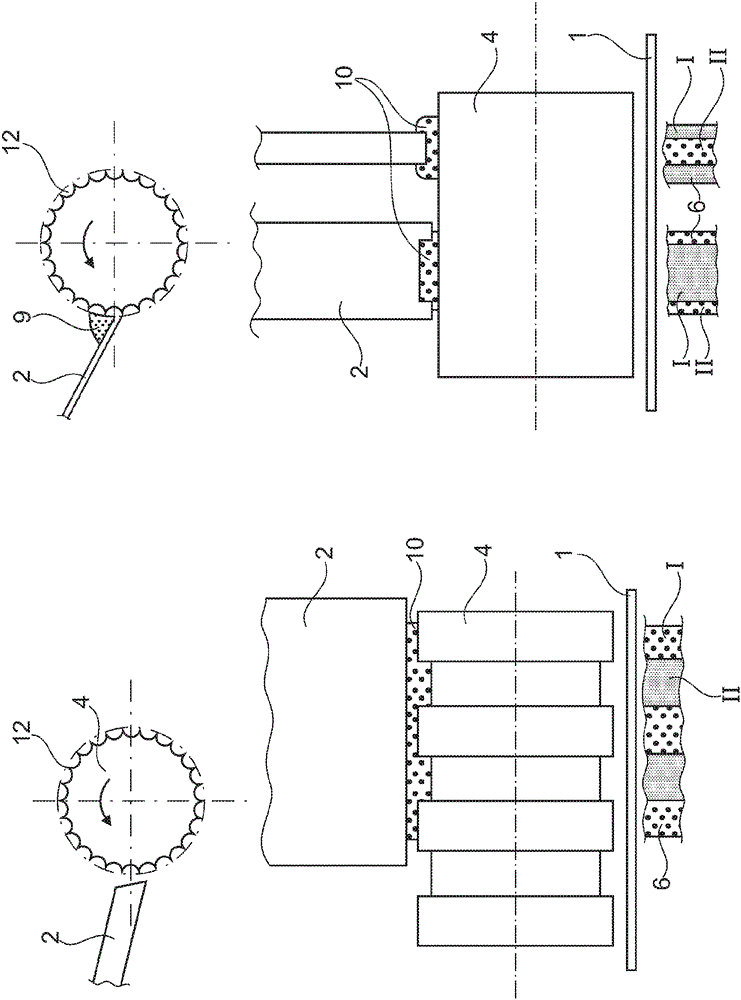

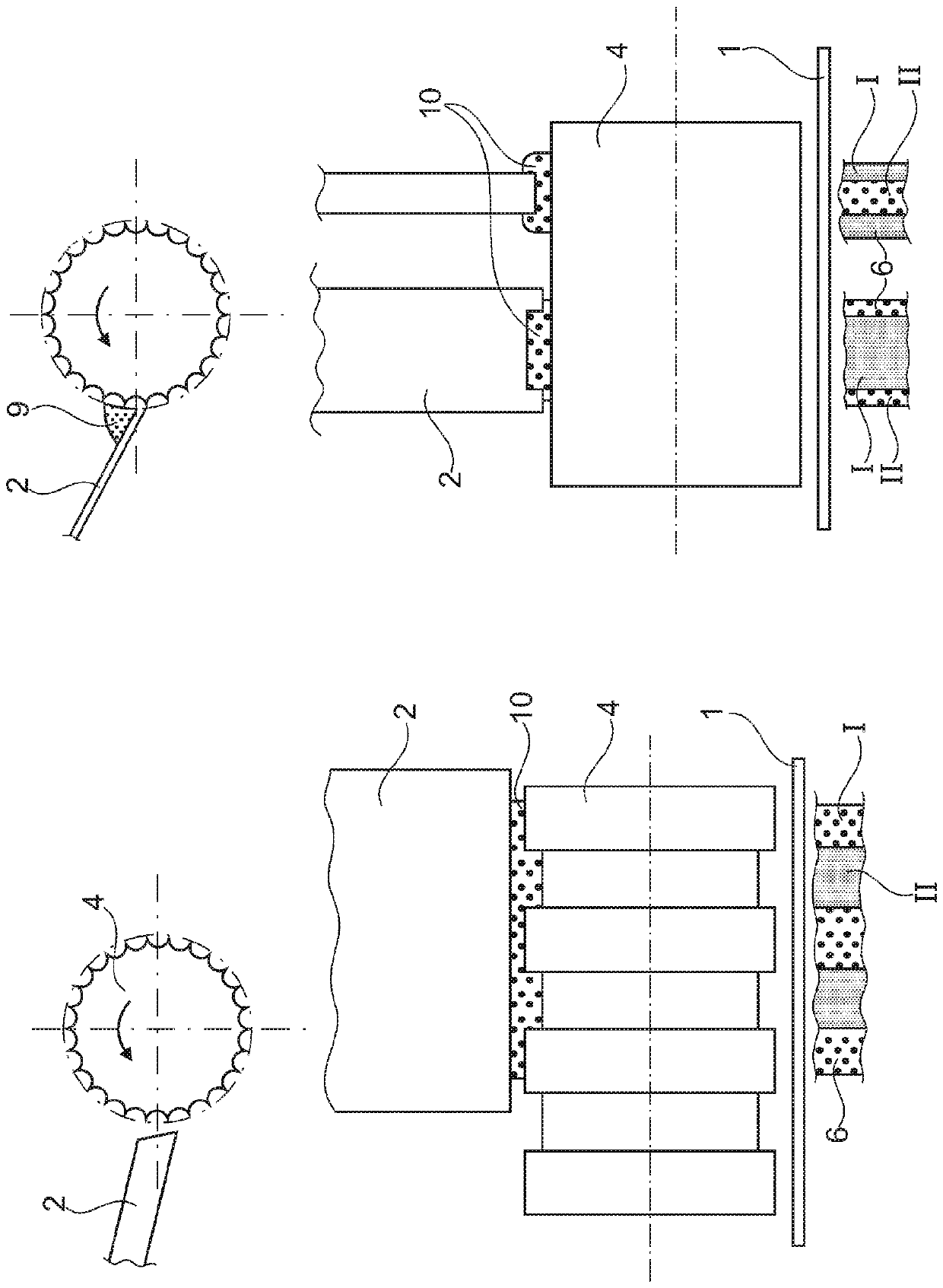

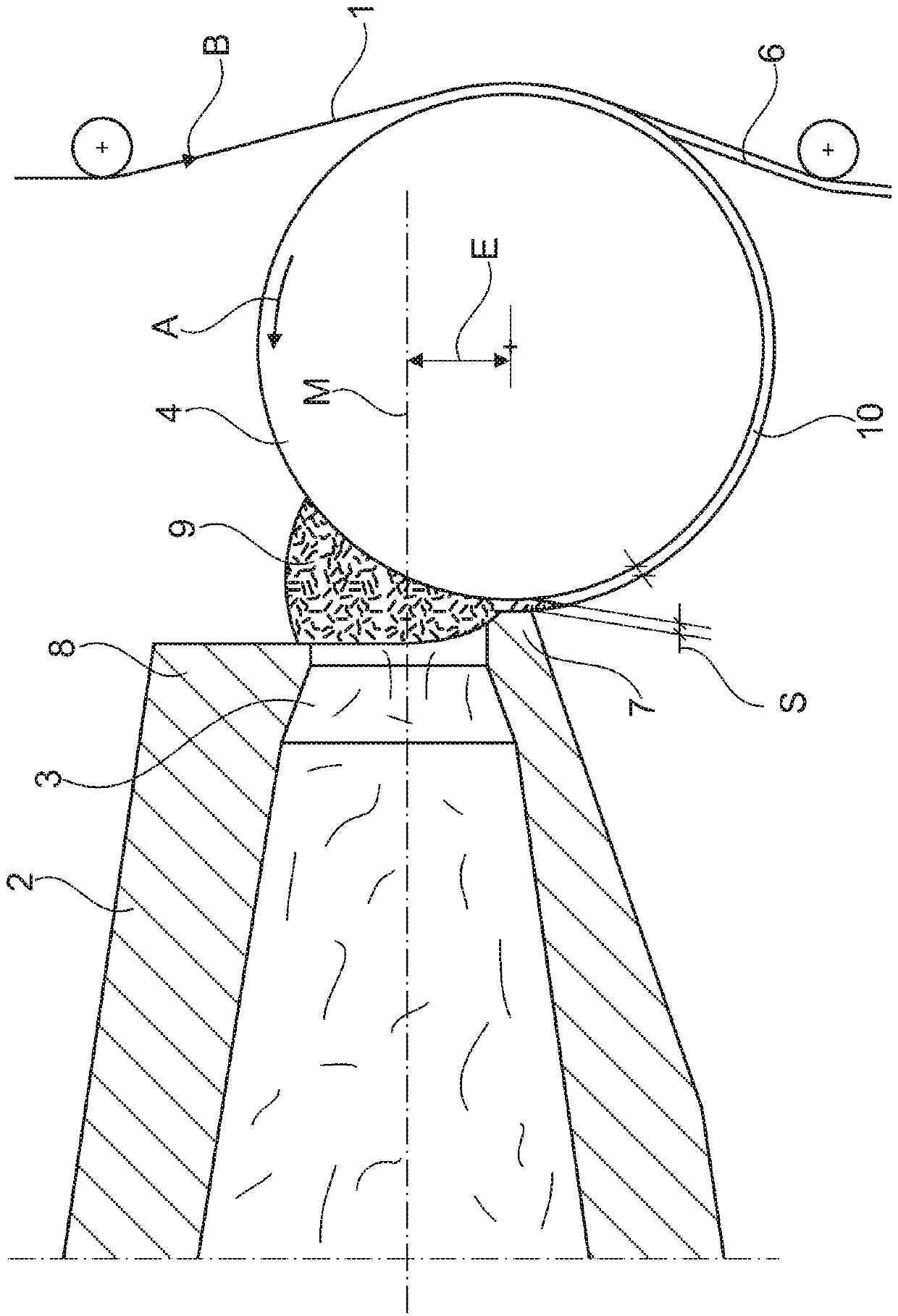

Device for applying a glue track to a wrapping strip of a rod-shaped product of the tobacco processing industry

ActiveCN105266192AGood adhesionFirmly connectedLiquid surface applicatorsCigarette manufactureEngineeringNozzle

The invention relates to a device for applying a glue track (6) to a wrapping strip (1) of a rod-shaped product of the tobacco processing industry. The device is provided with a nozzle (2) which is fixed relative to the wrapping strip (1) in a period of applying the glue track (6). The nozzle is provided with an outlet opening (3) which is aligned with the passing wrapping strip (1). The glue gets out through the outlet opening, wherein a roller (4) which can be rotated and driven through a driving device is arranged between the wrapping strip (1) and the outlet opening (3) of the nozzle (2). The glue which gets out of the outlet opening (3) is applied to the roller. Furthermore the roller directly applies the glue to the wrapping strip (1), wherein the rotation direction of the roller (4) is set so that the motion of the roller (4) is opposite to the motion of the wrapping strip (1) on the side surface which faces the passing wrapping strip (1).

Owner:KOERBER TECH GMBH

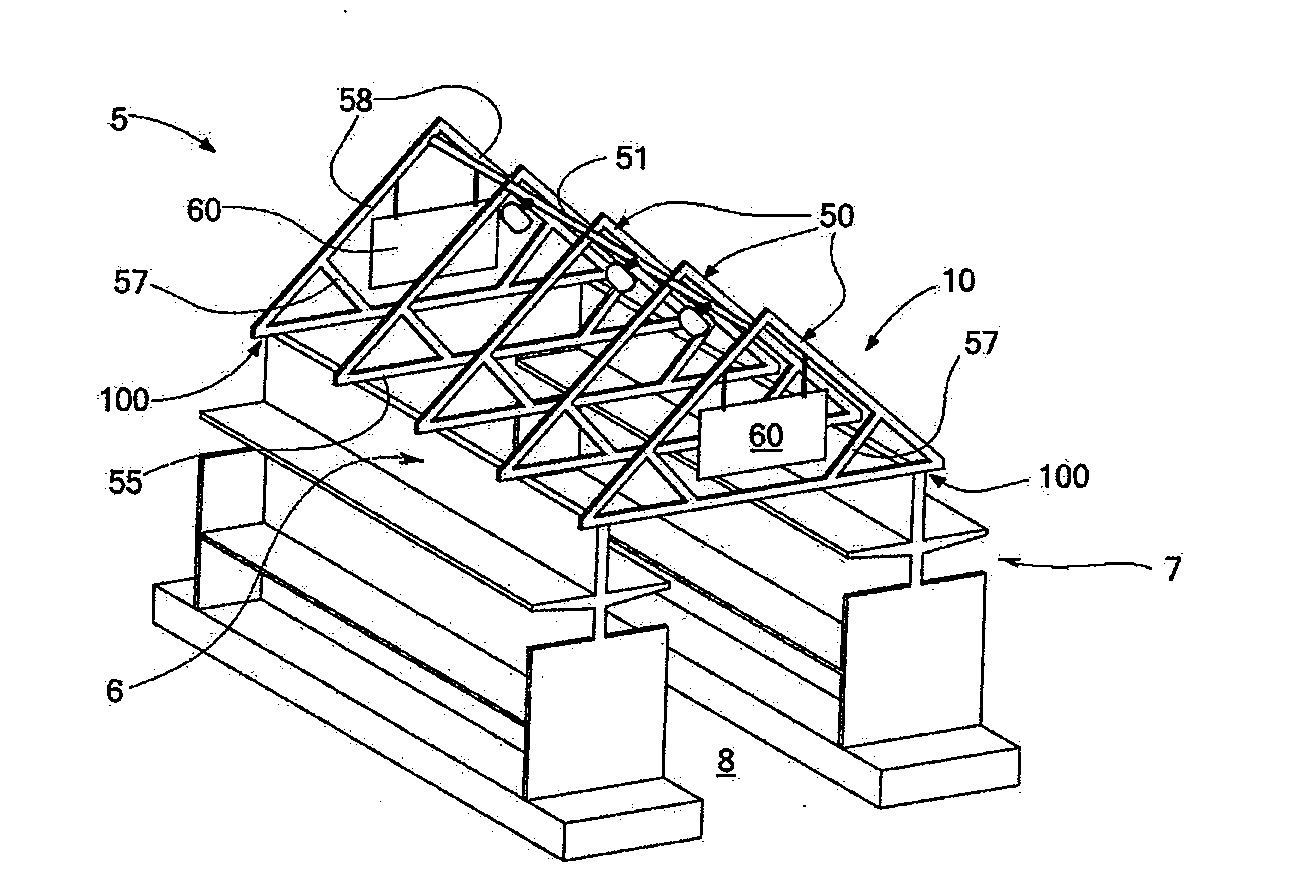

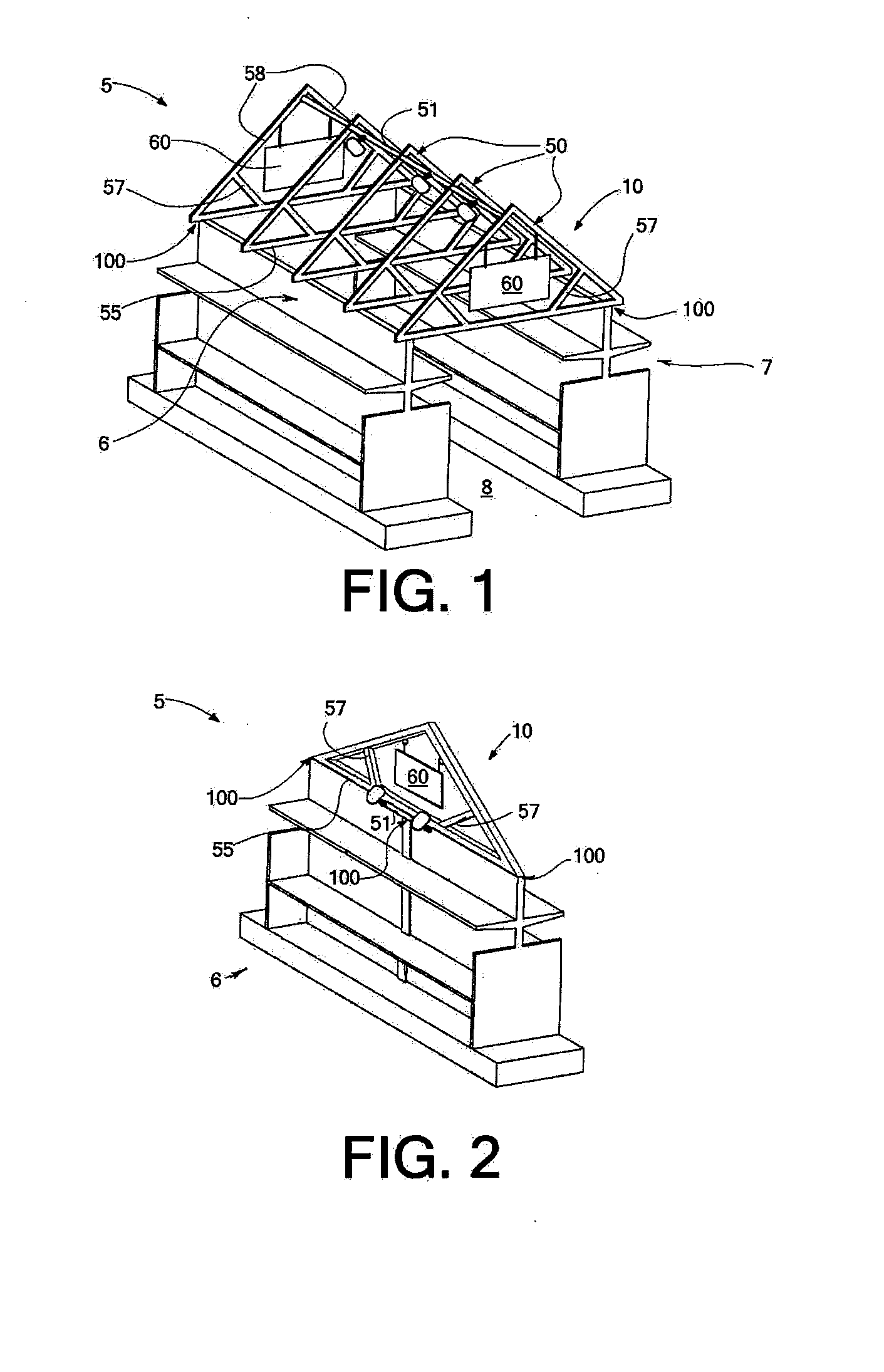

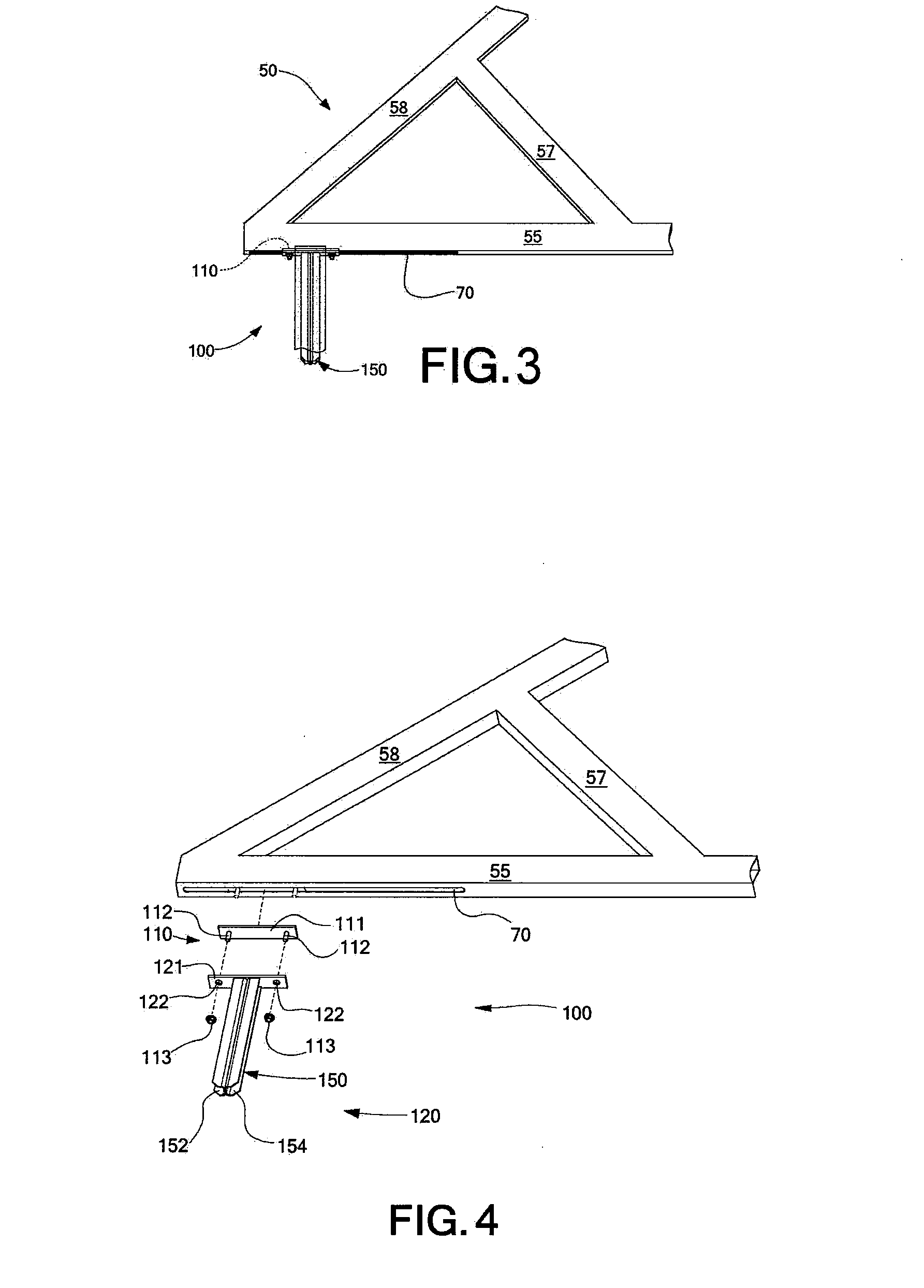

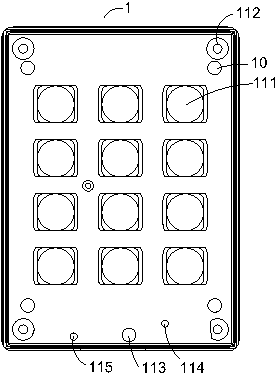

Structural Display having Adjustable mounting Widths for use in a Retail Environment

InactiveUS20090094905A1Improve stateVariable widthDiscounts/incentivesGirdersEngineeringMechanical engineering

Overhead truss assemblies for use with retail displays are provided. The assemblies include multiple trusses that are parallel to and spaced from each other, spanning overhead or otherwise elevated and connecting merchandise display racks on opposing sides of an aisle or aligned with and atop a single merchandise display rack. The trusses have horizontal truss segments and define variable mounting widths. The variable mounting widths are established with one or more connector assemblies that cooperate with and move longitudinally along the horizontal truss segments. Each connector assembly includes a captured plate that is slidingly housed inside of the horizontal truss segment, and an insert connected to and moving in unison with the captured plate. Moving the connector assembly inwardly toward a middle portion of the truss defines a relatively narrower mounting width, whilst moving the connector assembly outwardly toward an end of the truss defines a relatively wider mounting width.

Owner:HOBART BROS

Anti-peep intelligent key mechanical coded lock cylinder and coded lock

PendingCN107724797APrevent leakageEffective interferencePuzzle locksPermutation locksKey pressingPassword

The invention provides an anti-peep intelligent key mechanical coded lock cylinder and a coded lock. The lock cylinder comprises a lock cylinder shell, a bottom plate, a spring bolt, keys, a key locating plate, a movable plate, a mobile frame, a coding frame, a spring bolt control panel and a limiting sheet. According to the anti-peep intelligent key mechanical coded lock cylinder and the coded lock, any digits can be added in front of and behind a preset password, and the action is an anti-peep measure; as the added digit is arbitrary, the number of added digits is arbitrary; and therefore, an input password input at each time is ever-changing, and can effectively interfere with a peeper to achieve an effect of preventing password divulging.

Owner:青岛聚能达股权投资合伙企业(有限合伙)

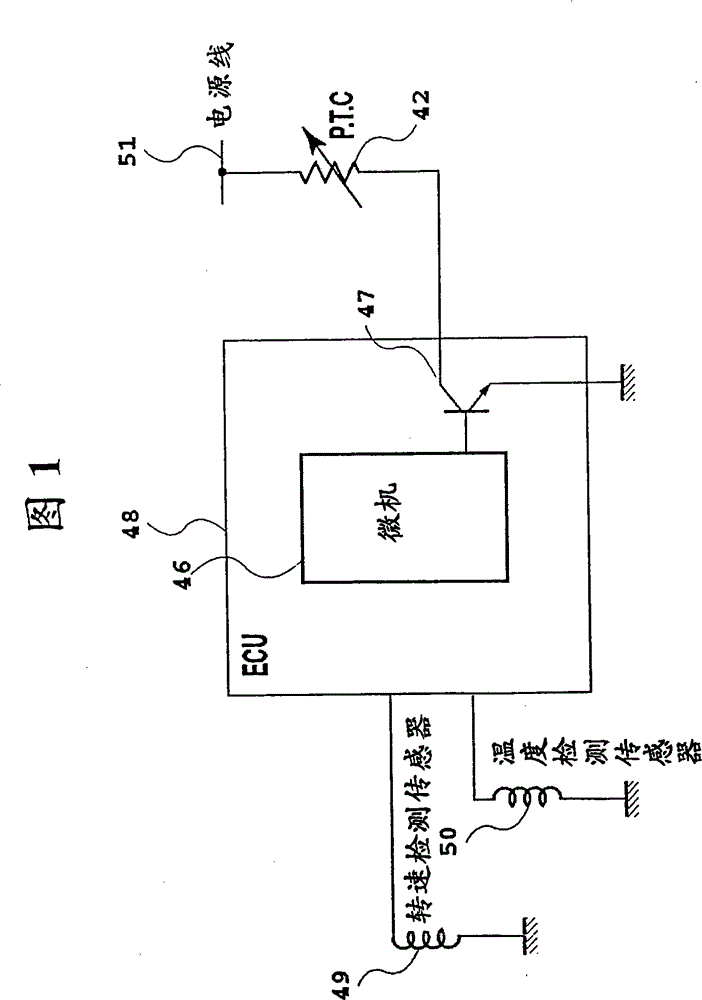

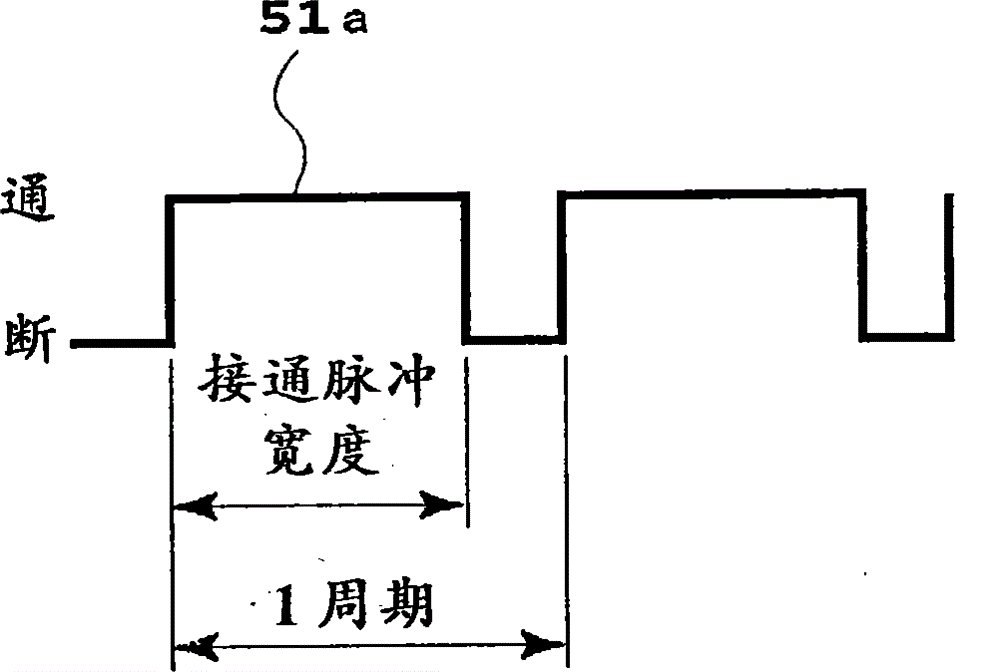

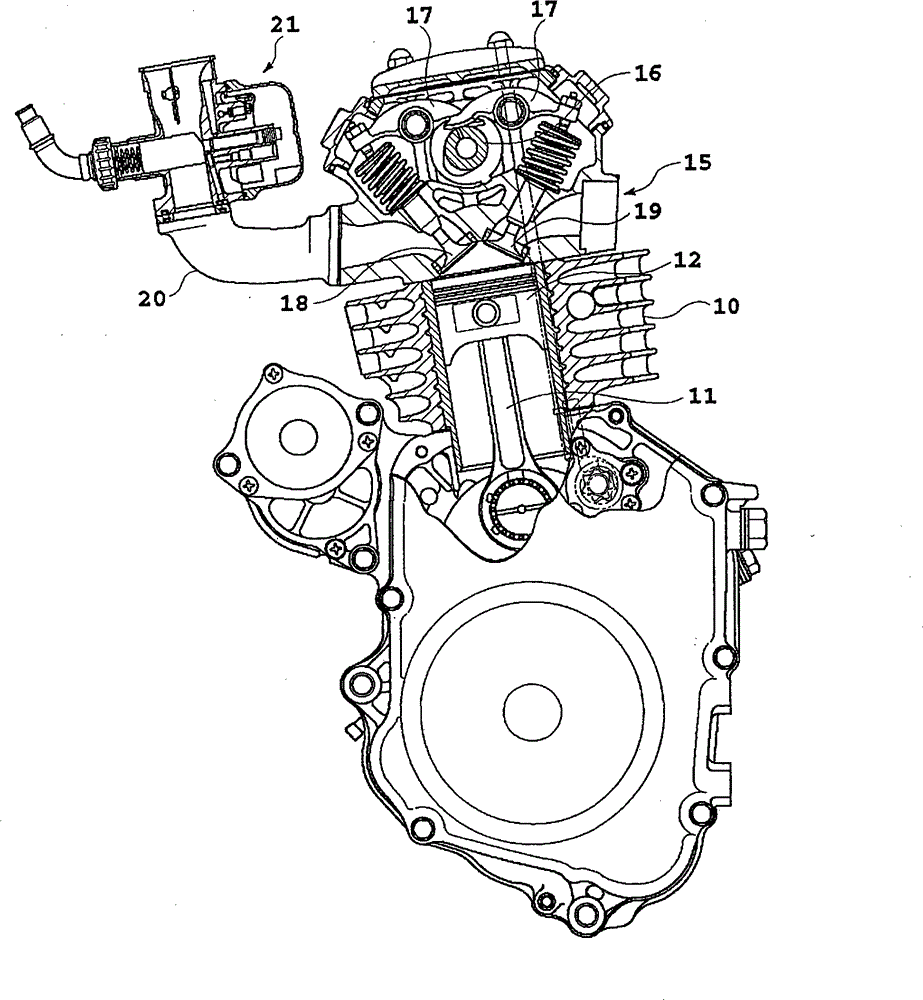

Automatic choke valve controlling device

The purpose of the invention is to improve accuracy of an auto choke controller without increasing a cost. When engine speed detected by an engine speed detection sensor 49 is above a set engine speed, energizing time to a PTC type heater 42 to be a heater for auto choke is made to be performed by a pulse control of a transistor 47 by a microcomputer 46, external resistance for regulating voltageto the heater for auto choke conventionally used can be unnecessitated. When the auto choke is applied to an engine of a different characteristics, the application can be easily coped by changing an on-pulse width in the microcomputer 46 according to the characteristics of an applied engine.

Owner:HONDA MOTOR CO LTD

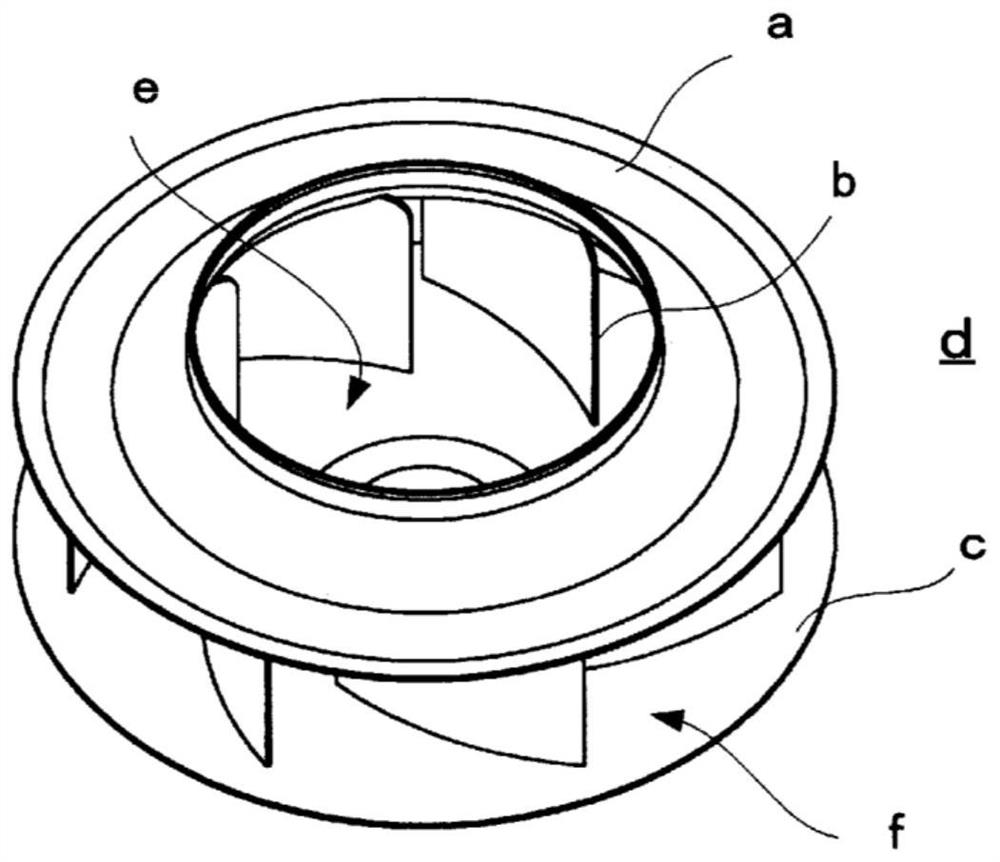

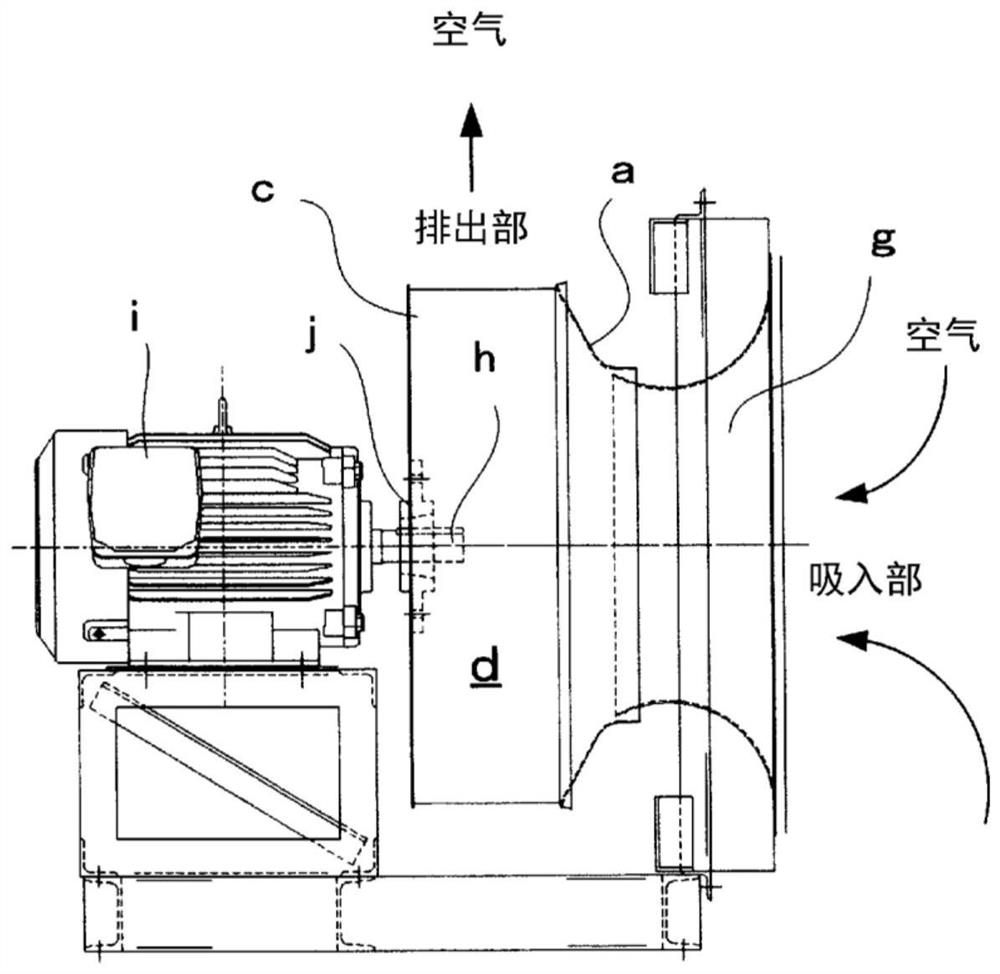

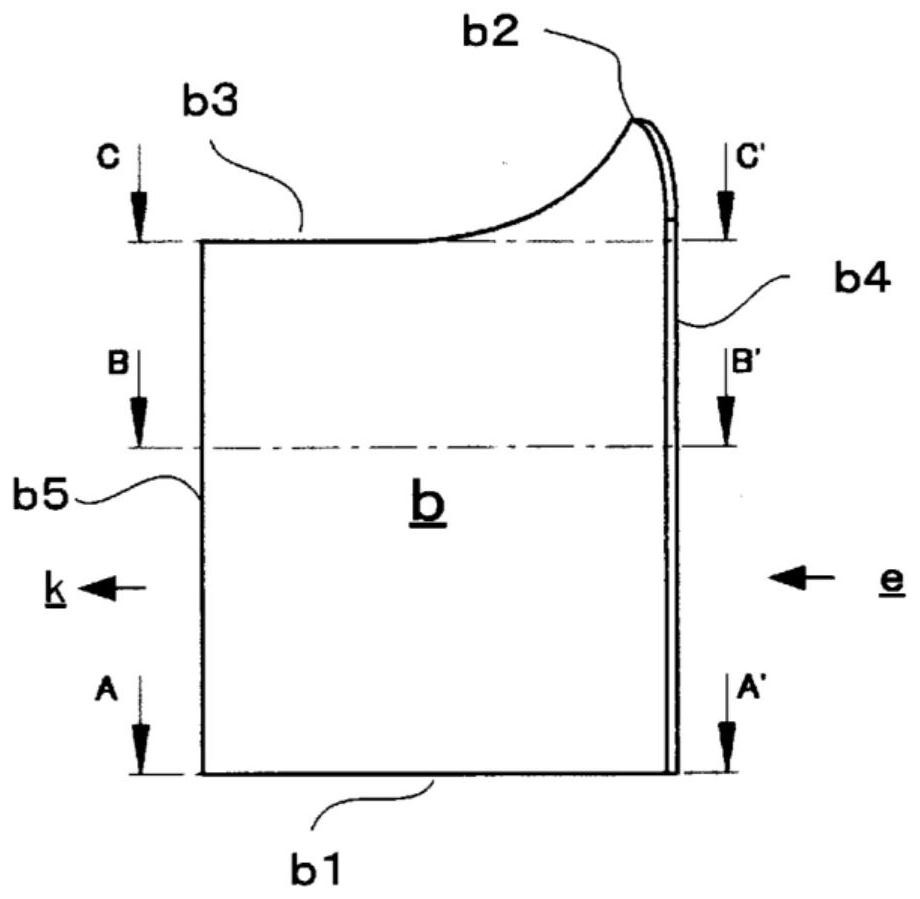

Blade structure of centrifugal blower

PendingCN111648998AInflow status improvedSuppress turbulencePump componentsPumpsAir blowerFront edge

The invention provides a blade structure of a centrifugal blower, which can obtain blowing efficiency and noise reduction effect. A centrifugal blower in which a plurality of blades are erected between a back plate and a shroud disposed at a predetermined interval from the back plate, the vicinity of the leading edge portions of the blades in the blade rotation direction on the back plate side andthe shroud side being in a twisted shape that curves in the outer circumferential direction in the vicinity of the back plate and the shroud of the blades, and the shroud being disposed at a predetermined interval from the back plate. Subsequent parts, connected with the torsion shape, of the blades are the same cylindrical plane, the shape of the edge of the front edge part is a bending shape with a concave central part, and the central part in the width direction of the blades is also the same cylindrical plane from the front edge part to the subsequent parts.

Owner:SHINKO IND CO LTD (JP)

Apparatus for applying glue marks to wrapping strips of tobacco rod-shaped articles

ActiveCN105266192BGood adhesionFirmly connectedLiquid surface applicatorsCigarette manufactureComing outEngineering

The invention relates to a device for applying an offset (6) to a moving wrapping strip (1) of rod-shaped products in the tobacco processing industry, with a relative The wrapping strip (1) has a fixed nozzle (2) which has an outlet opening (3) directed towards the passing wrapping strip (1), from which outlet opening the glue emerges, wherein the wrapping strip ( Between 1) and the outlet opening (3) of the nozzle (2) there is a roller (4) which can be driven in rotation via a drive, onto which the glue coming out of the outlet opening (3) is applied and which will Glue is applied directly onto the wrapping web (1), wherein the direction of rotation of the rollers (4) is oriented such that the movement of the rollers (4) on the side facing the passing wrapping web (1) coincides with The movement of the wrapping strip (1) is directed in the opposite direction.

Owner:KOERBER TECH GMBH

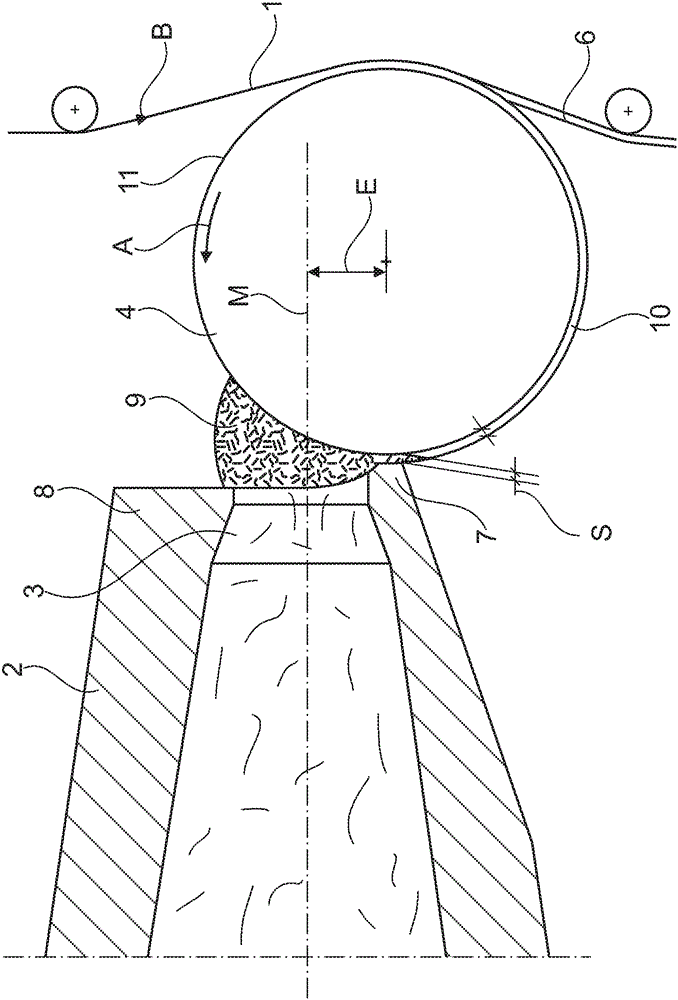

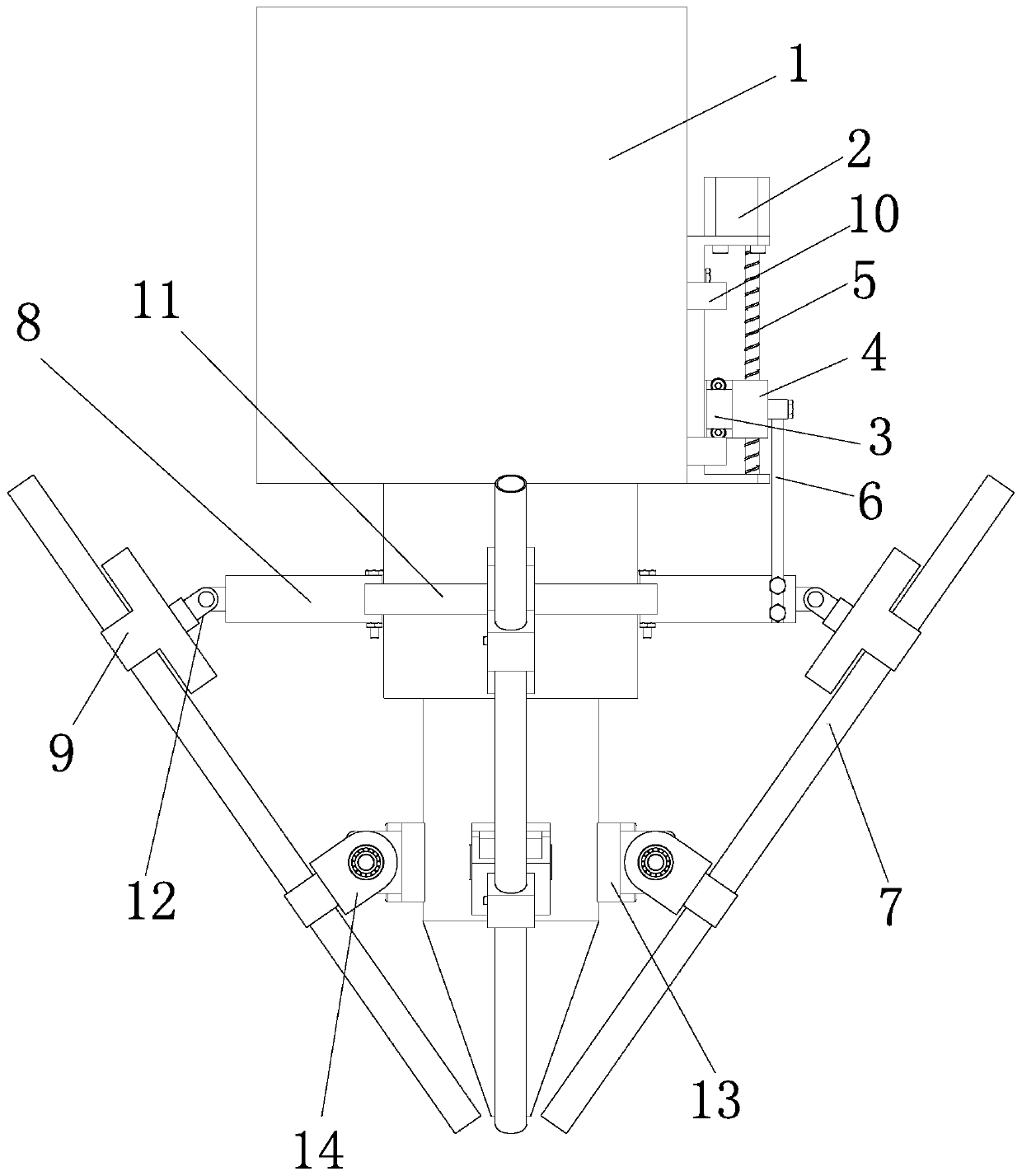

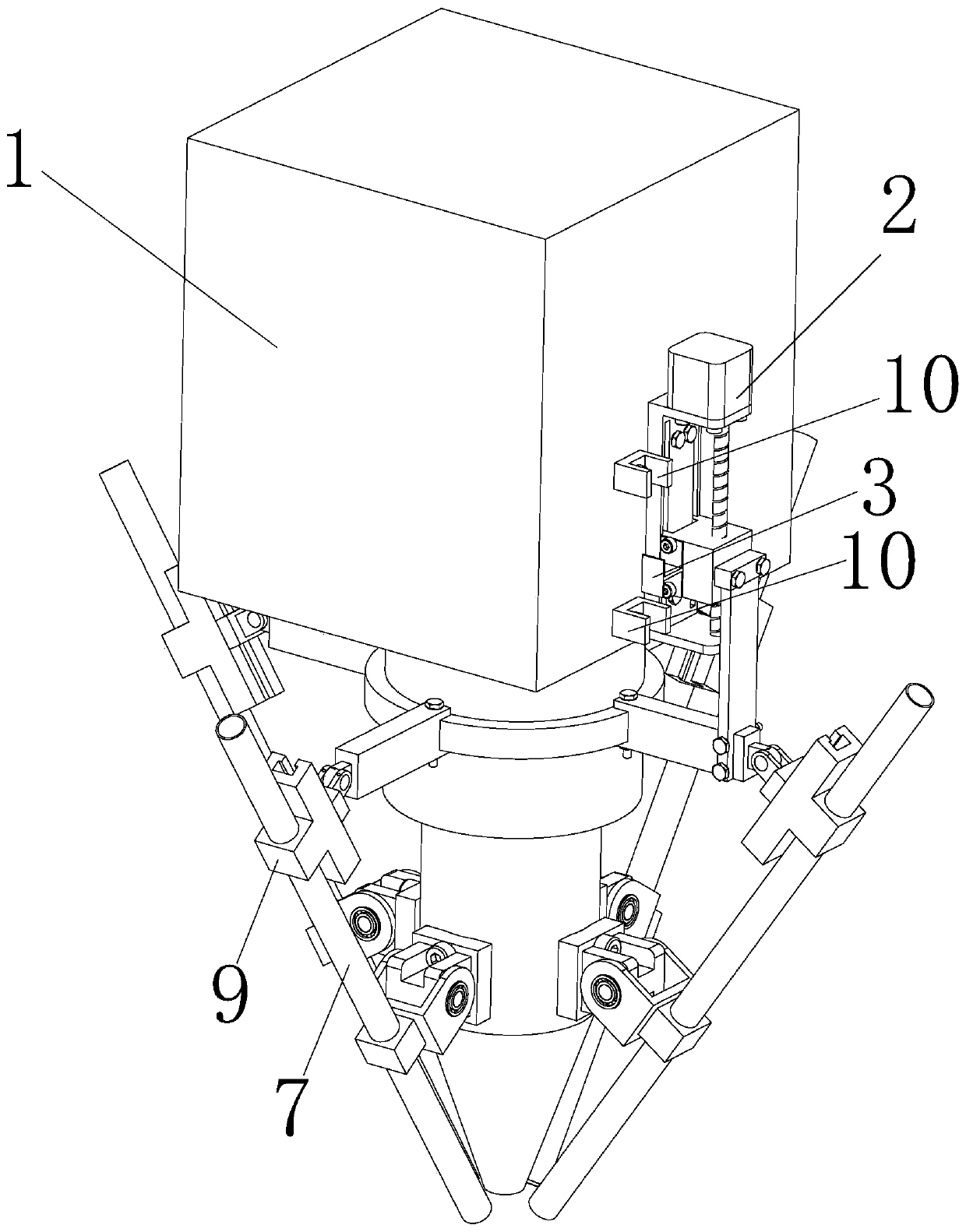

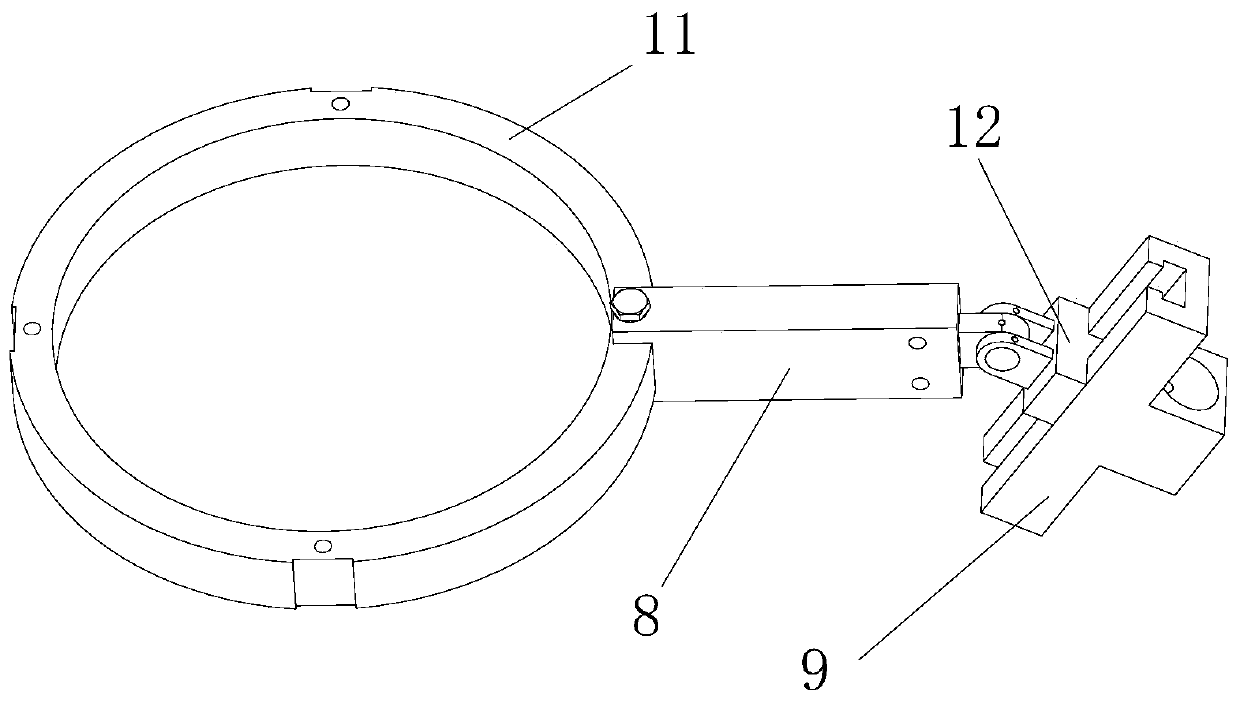

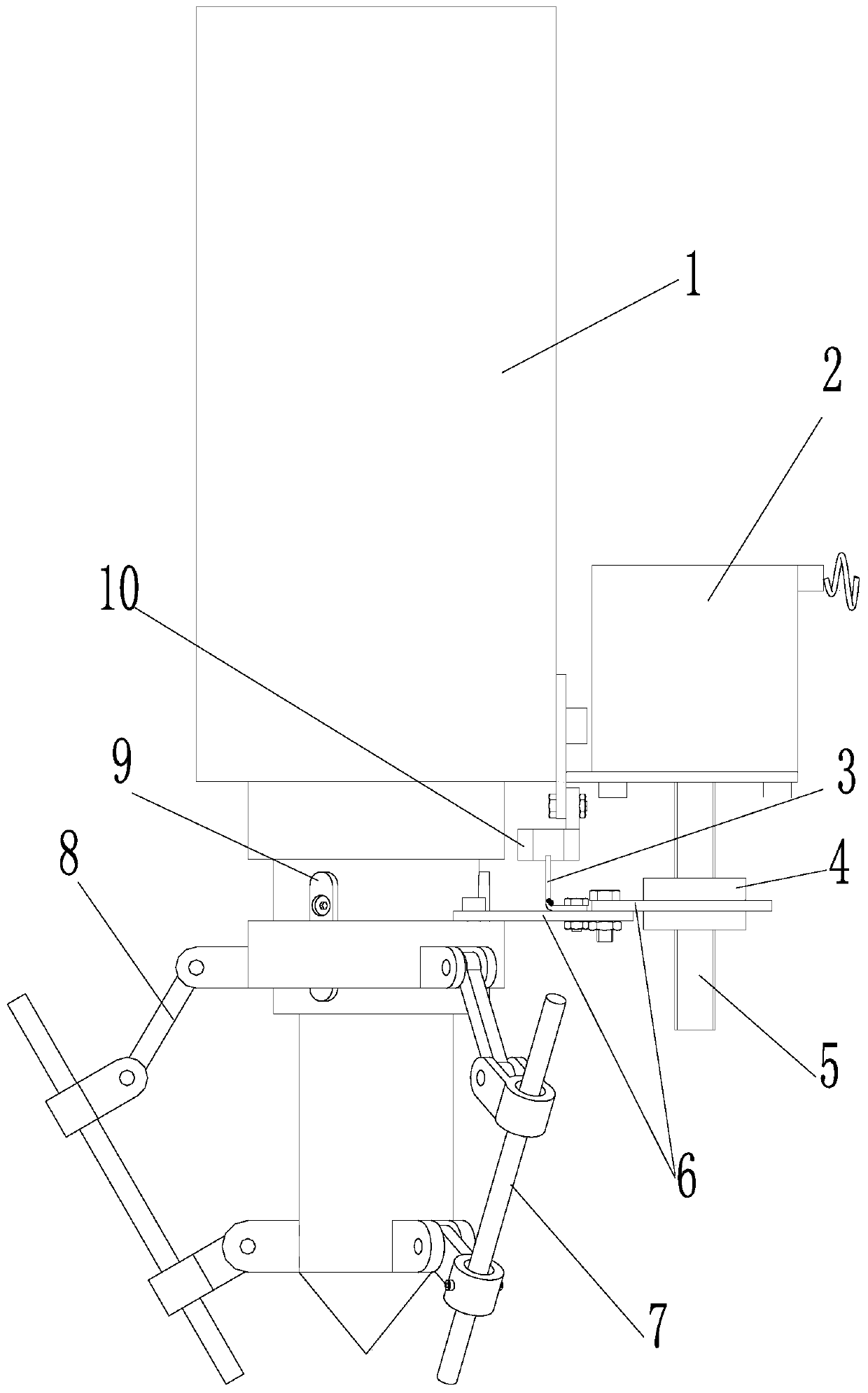

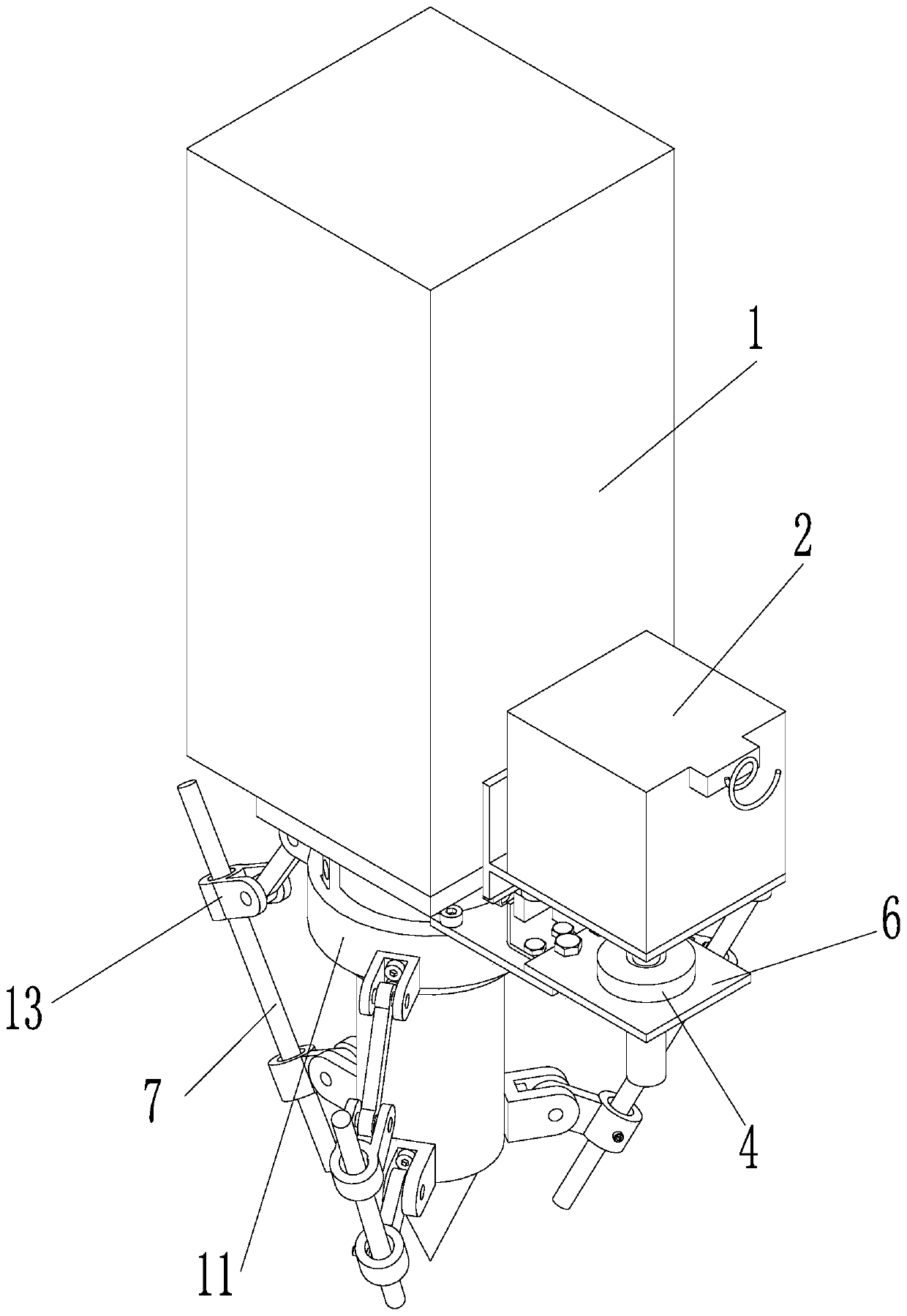

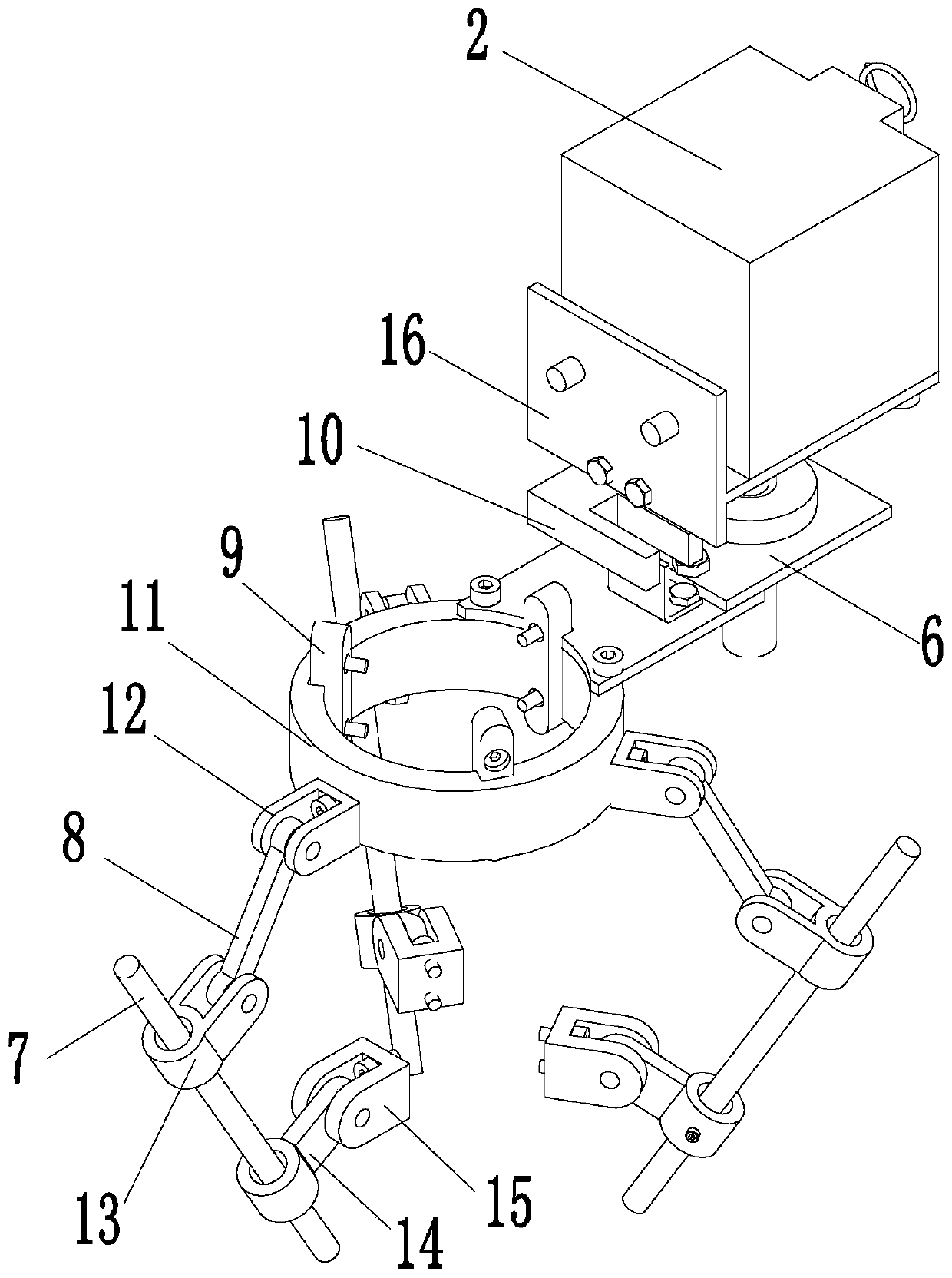

A hinged slider laser coaxial powder feeding nozzle with adjustable powder focus

ActiveCN106801226BHigh precisionQuality improvementMetallic material coating processesMachine partsEngineering

Provided is a hinge and sliding block type laser coaxial powder feeding nozzle with the adjustable powder focal point. Powder feeding pipes are arranged outside a cladding head and located on the periphery of the cladding head through angle adjusting devices. Each angle adjusting device comprises a sleeve, wherein a driving device is arranged on one side of the sleeve. Each powder feeding pipe is located outside the corresponding sleeve, and a sliding rail part is arranged at the end, close to an inlet of each powder feeding pipe. A sliding block part is fixed to each sleeve and slidably arranged on the corresponding sliding rail part, and each sliding block part is connected with the corresponding sliding rail part through a buckle device to prevent the sliding block part from being separated from the sliding rail part in the sliding process. The end, close to an outlet, of each powder feeding pipe is hinged to the cladding head. A central controller is connected with the driving devices. The hinge and sliding block type laser coaxial powder feeding nozzle can dynamically adjust the powder gathering point in real time while the laser defocusing amount is changed, the powder gathering point is made to be located on the surface of a machined part all the time, a clad layer high in precision and quality and good in performance is obtained, and the cladding track width can be changed.

Owner:ZHEJIANG UNIV OF TECH

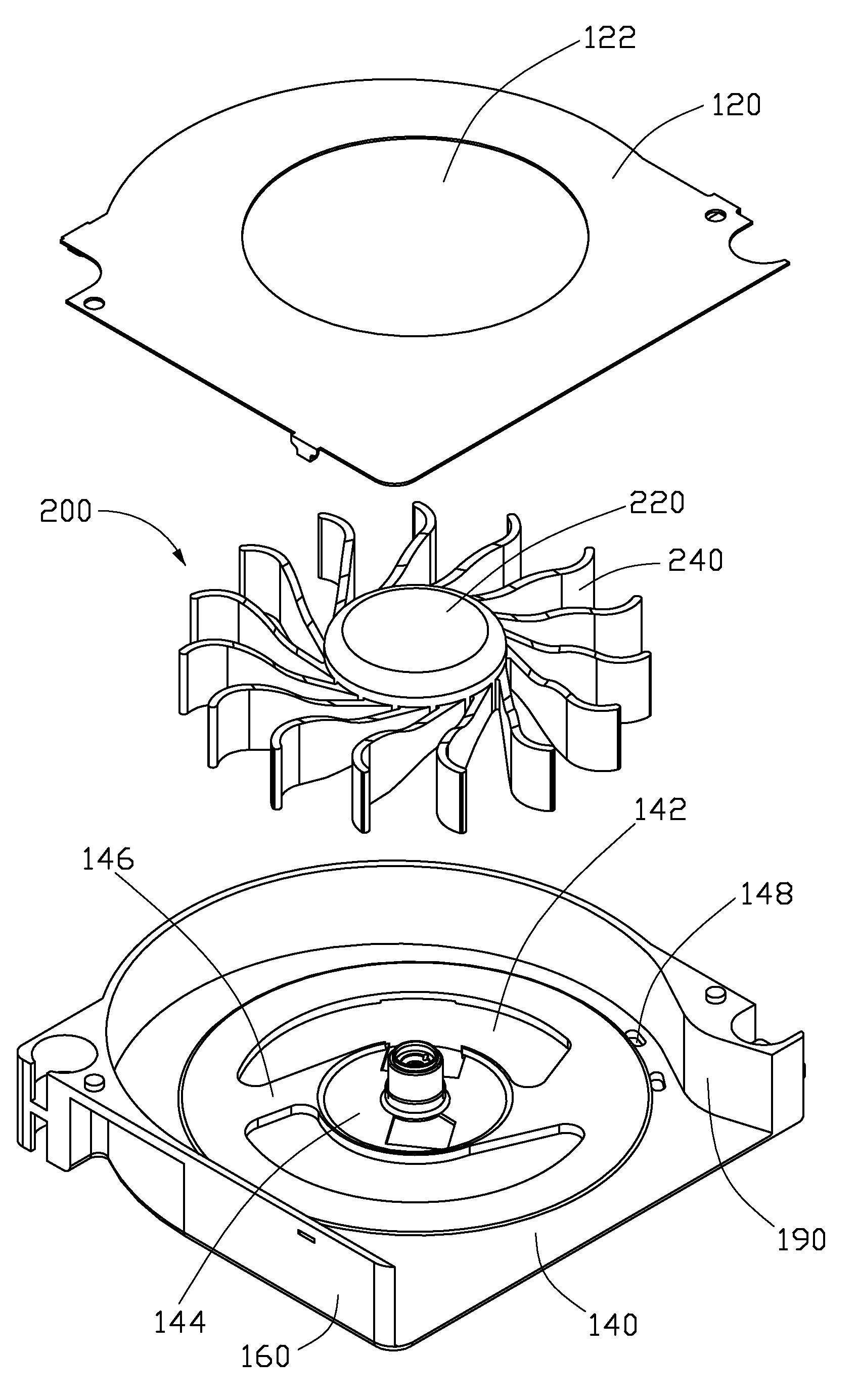

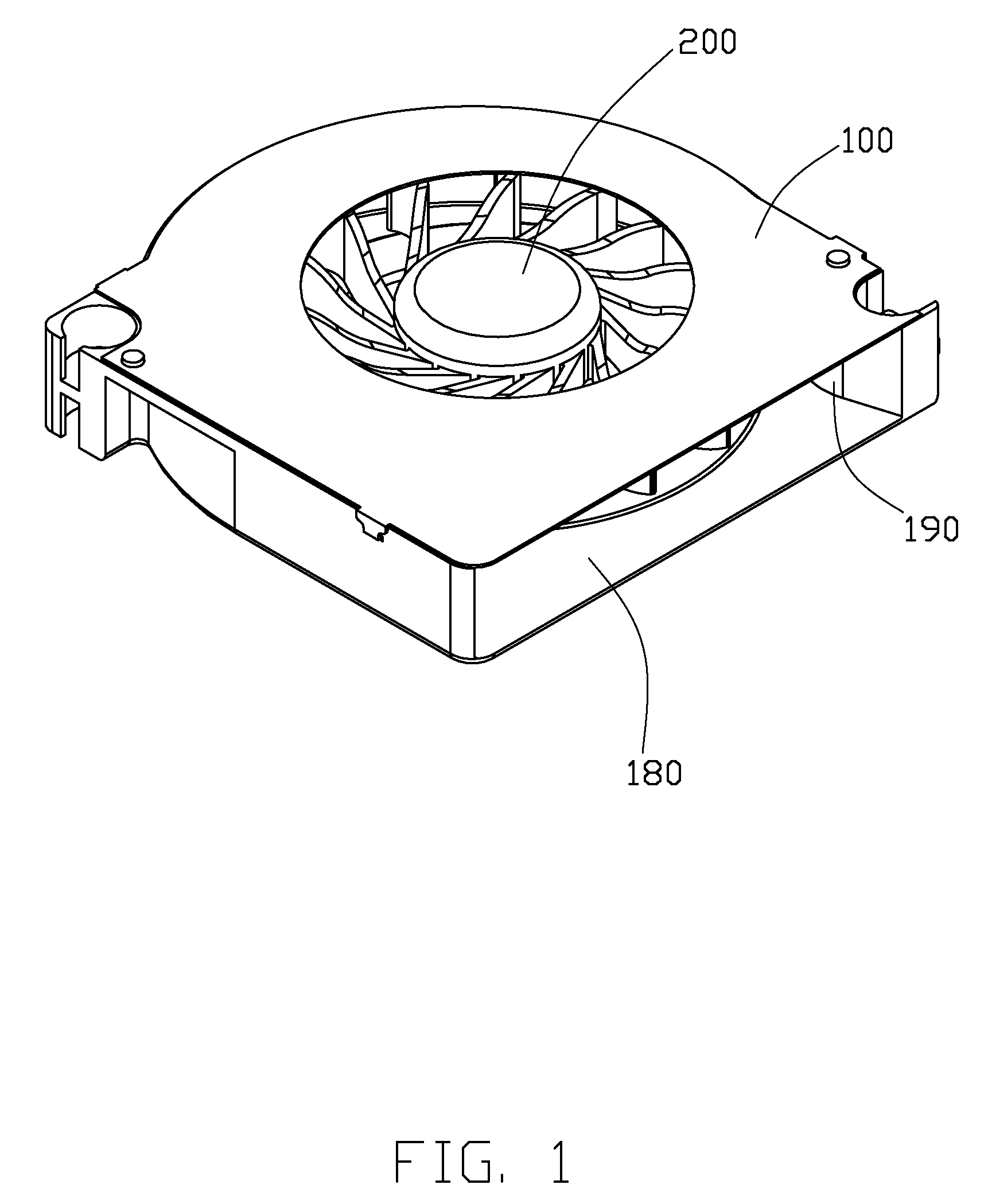

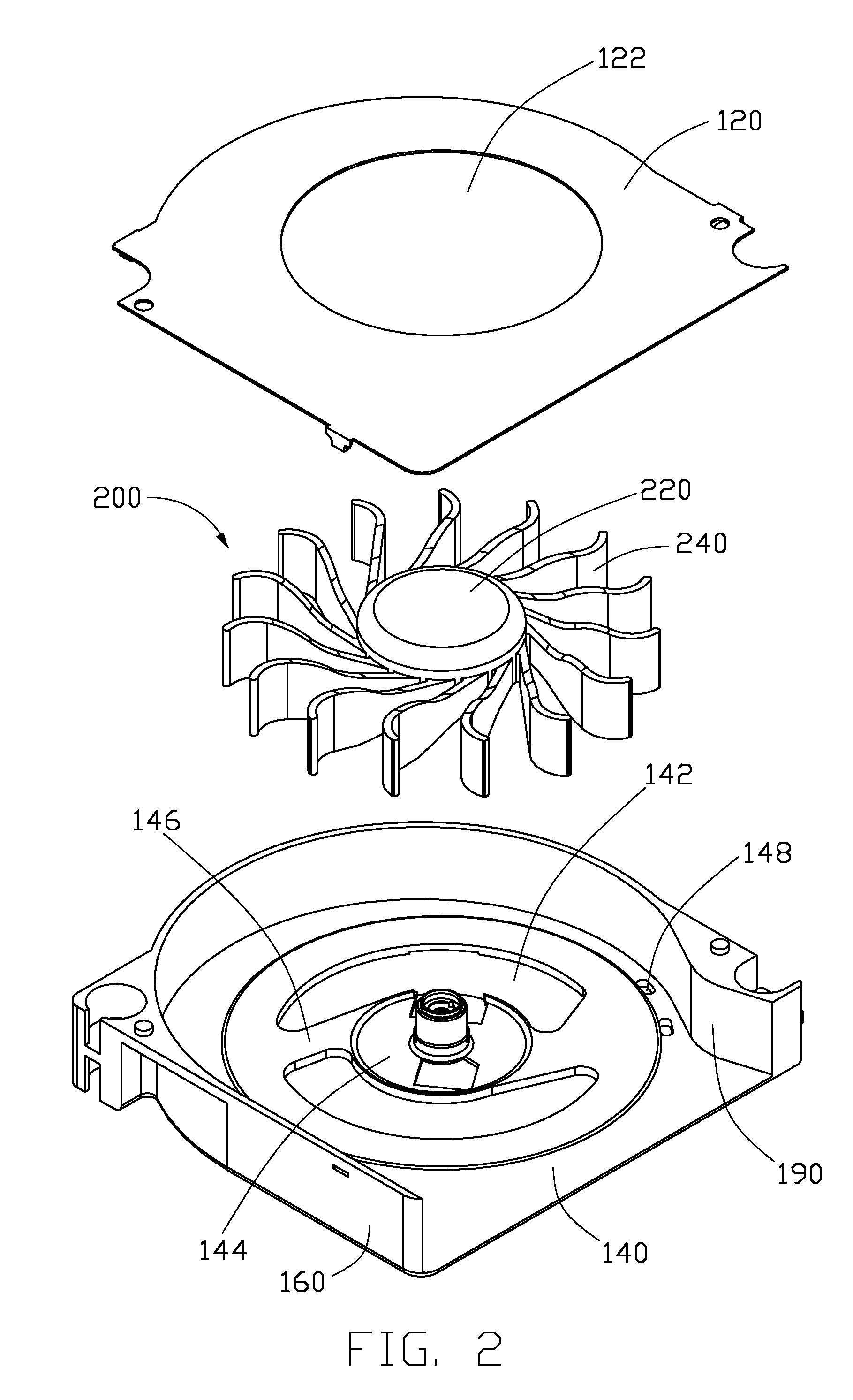

Cooling fan

A cooling fan includes a frame (100) and an impeller (200) with blades (240) disposed in the frame (100). The frame (100) has a base (140) and a sidewall (160) extending from a periphery of the base (140) with an air outlet (180) defined therein. The base (140) has an air inlet (142) and a vent hole (148) defined therein. The vent hole (148) is near the air outlet (180) and between tip portions of the blades (240) and the sidewall (160). In a preferred embodiment, the base (140) has a supporting portion (144) disposed in the air inlet (142). Two ribs (146) extend from a periphery of the supporting portion (144) towards the base (140). One of the ribs (146) is arranged adjacent to the air outlet (180) and has a changeable width which is gradually increased along a direction from the supporting portion (144) to the base (140).

Owner:FU ZHUN PRECISION IND SHENZHEN +1

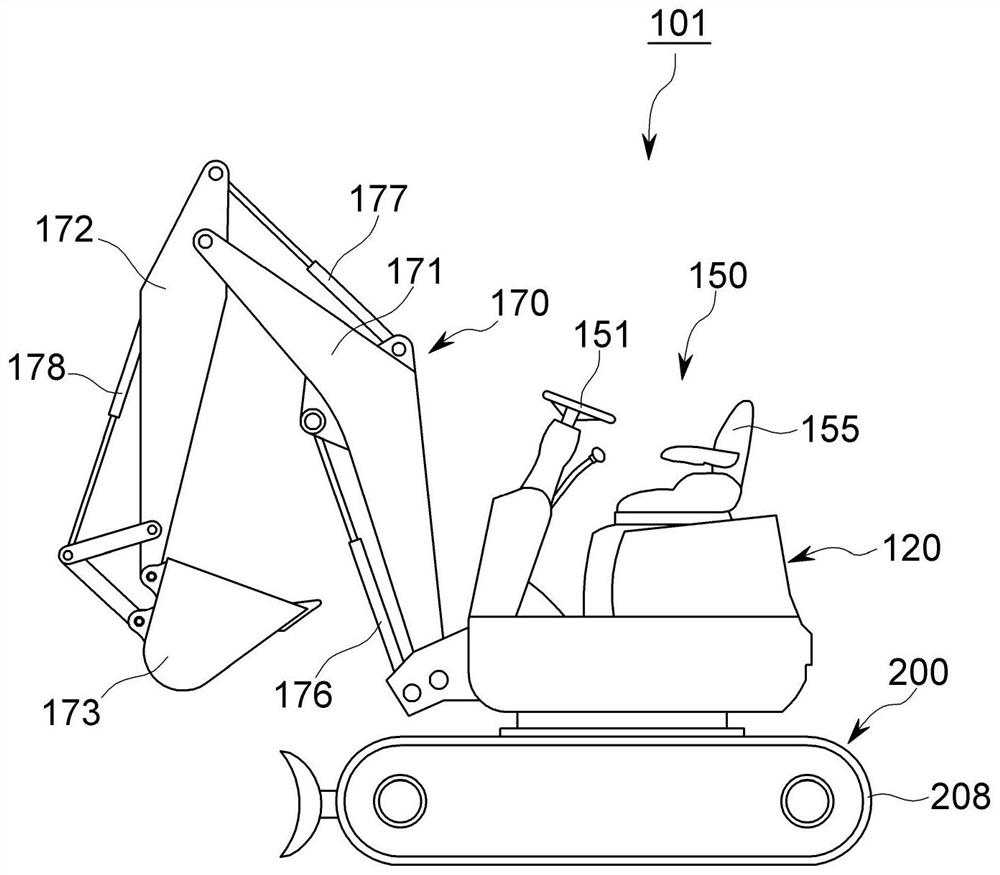

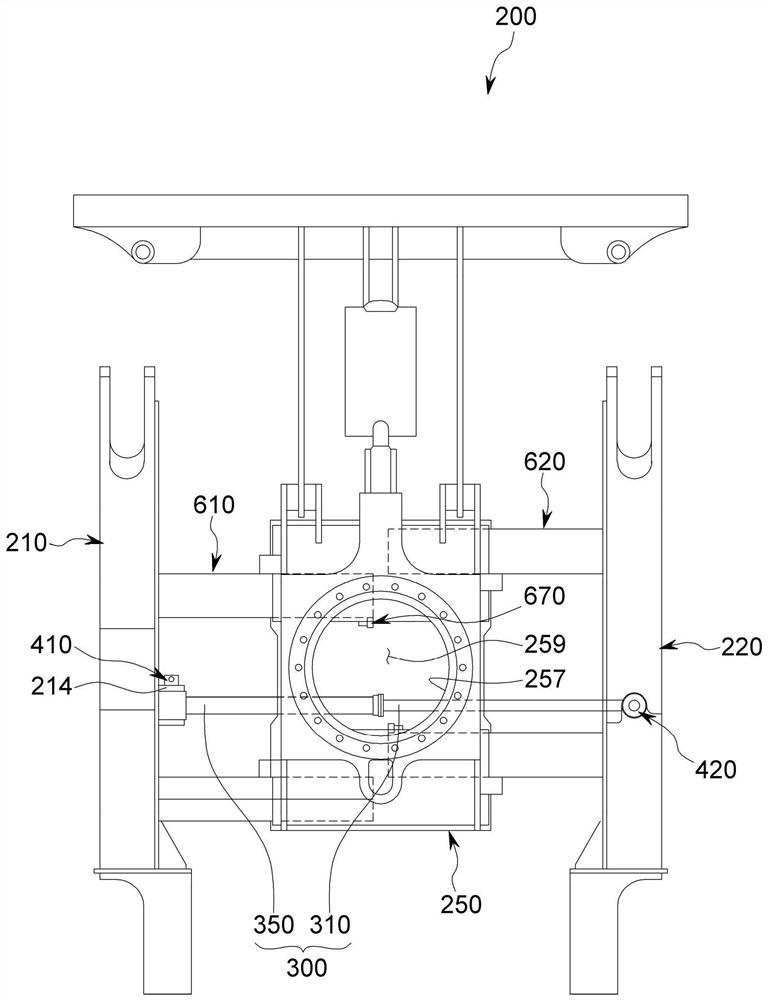

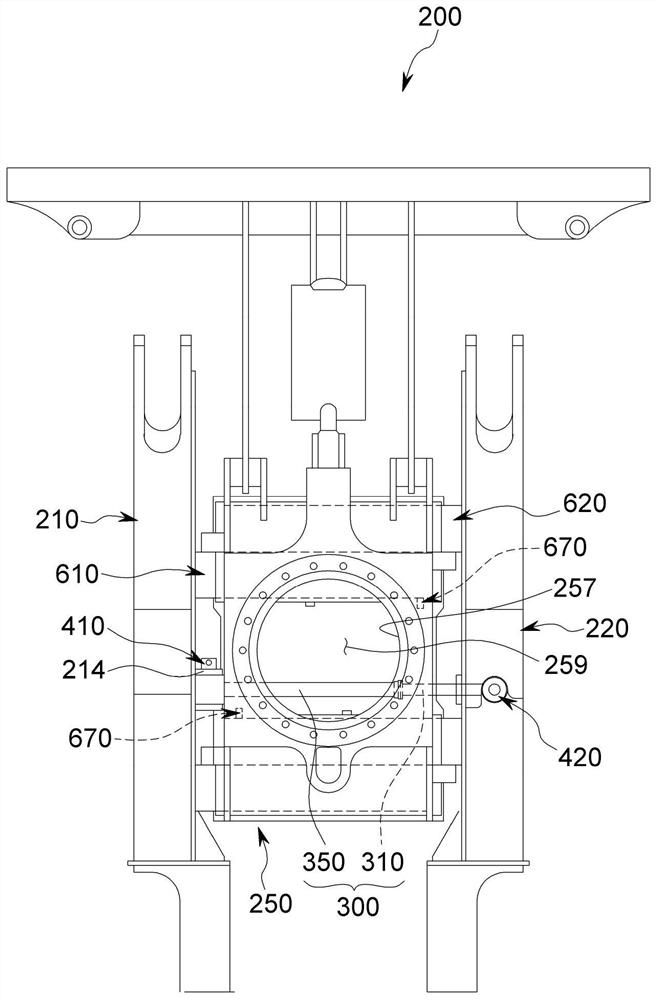

Construction machinery

ActiveCN112196001AVariable widthMechanical machines/dredgersUnderstructuresPhysicsMechanical engineering

Owner:DOOSAN INFRACORE CO LTD

A laser coaxial powder feeding nozzle with adjustable powder convergence point of connecting rod and lever structure

ActiveCN106835125BHigh precisionQuality improvementMetallic material coating processesEngineeringLaser

A link-lever structured laser coaxial powder-feeding nozzle with an adjustable powder gathering point is characterized in that powder-feeding pipes are arranged outside a cladding head, the powder-feeding pipes are mounted around the cladding head through an angle adjuster that may adjust the included angles between the powder-feeding pipes and the cladding head, each powder-feeding pipe has a downward outlet that is close to a laser outlet, the angle adjuster comprises a sleeve that sleeves the cladding head, one side of the sleeve is provided with a driving device that drives the sleeve to slide up and down along the outer wall of the cladding head, a guiding device is arranged between the sleeve and the cladding head, one end of each powder-feeding pipe close to an inlet is connected to the sleeve through a link, one end of each link is hinged to the corresponding powder-feeding pipe, the other end of each link is hinged to the sleeve, one end of each powder-feeding pipe close to the outlet is hinged to the cladding head, and a central control unit is connected to the driving device. The link-lever structured laser coaxial powder-feeding nozzle with the adjustable powder gathering point allows the powder gathering point to be adjusted dynamically in real time, allows the powder gathering point to fall constantly on the surface of a part under processing, and can provide high-precision high-quality high-performance clad layer with adjustable width of a cladding path.

Owner:ZHEJIANG UNIV OF TECH

One-step molding technique of carbon stirrup and used stirrup-molding mould thereof

ActiveCN100589897COne-time forming process is simpleImprove forming qualityMetal-working apparatusEngineeringForming processes

The invention discloses a one step forming process of carbon clip and a clip resizer adopting the method. The method is a one step clip forming technique with simple process, high forming quality andhigh forming speed. The invention forms a clip at one step by lowering a plurality of clip forming cutters in the clip resizer on a sheet-forming machine. The method includes the following steps: thefirst step: the feed wheels of a sheet-forming machine deliver the blanks of carbon strips to perforating dies; the second step: the perforating dies punch the blanks, thus producing a plurality of holes simultaneously; the third step: the feed wheels continue to deliver the blanks, wherein, the blanks with holes punched by the perforating dies are delivered into the clip resizer to process the blanks with holes into formed clips at one step. The one step forming process of carbon clip provided by the invention is characterized by simple process, high forming quality and rapid forming speed, and the inside diameter of the formed clips and the thickness and the width of the plank stuff are changeable. The invention plays a good role in improving the highly efficient mass production of comparable products.

Owner:SHANGHAI SPRING CORP

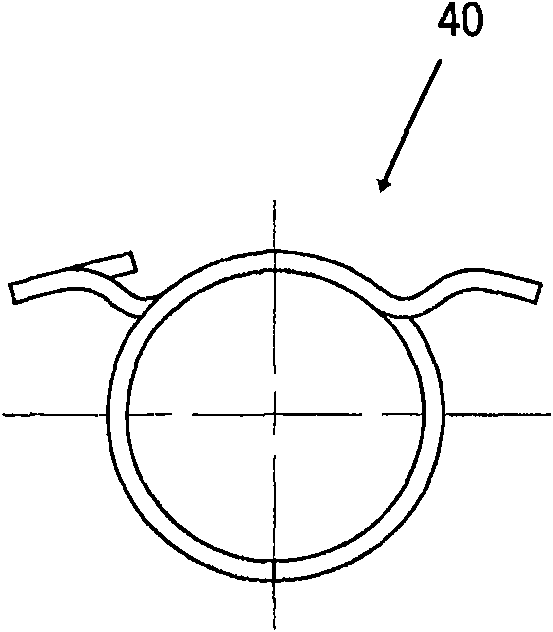

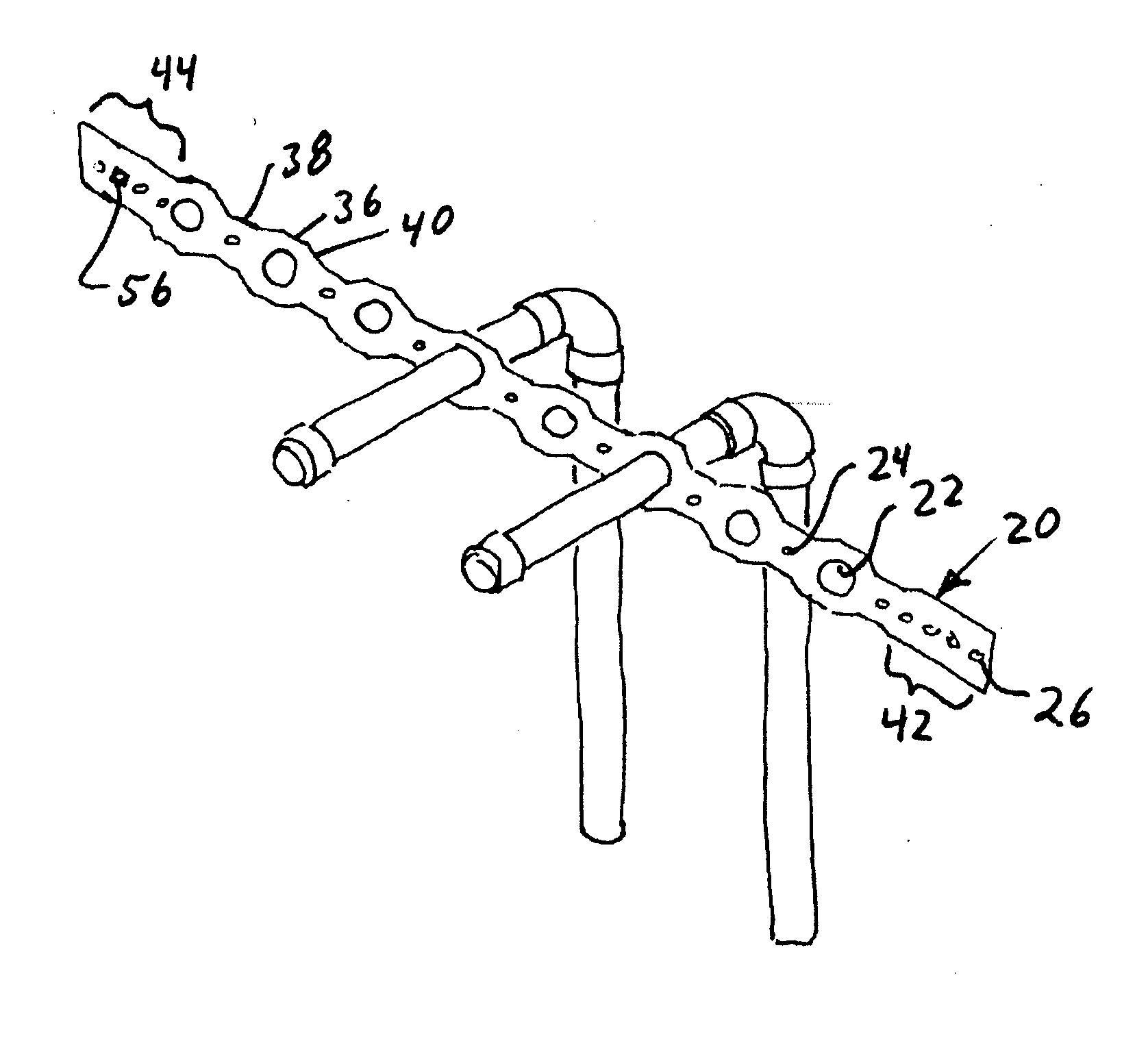

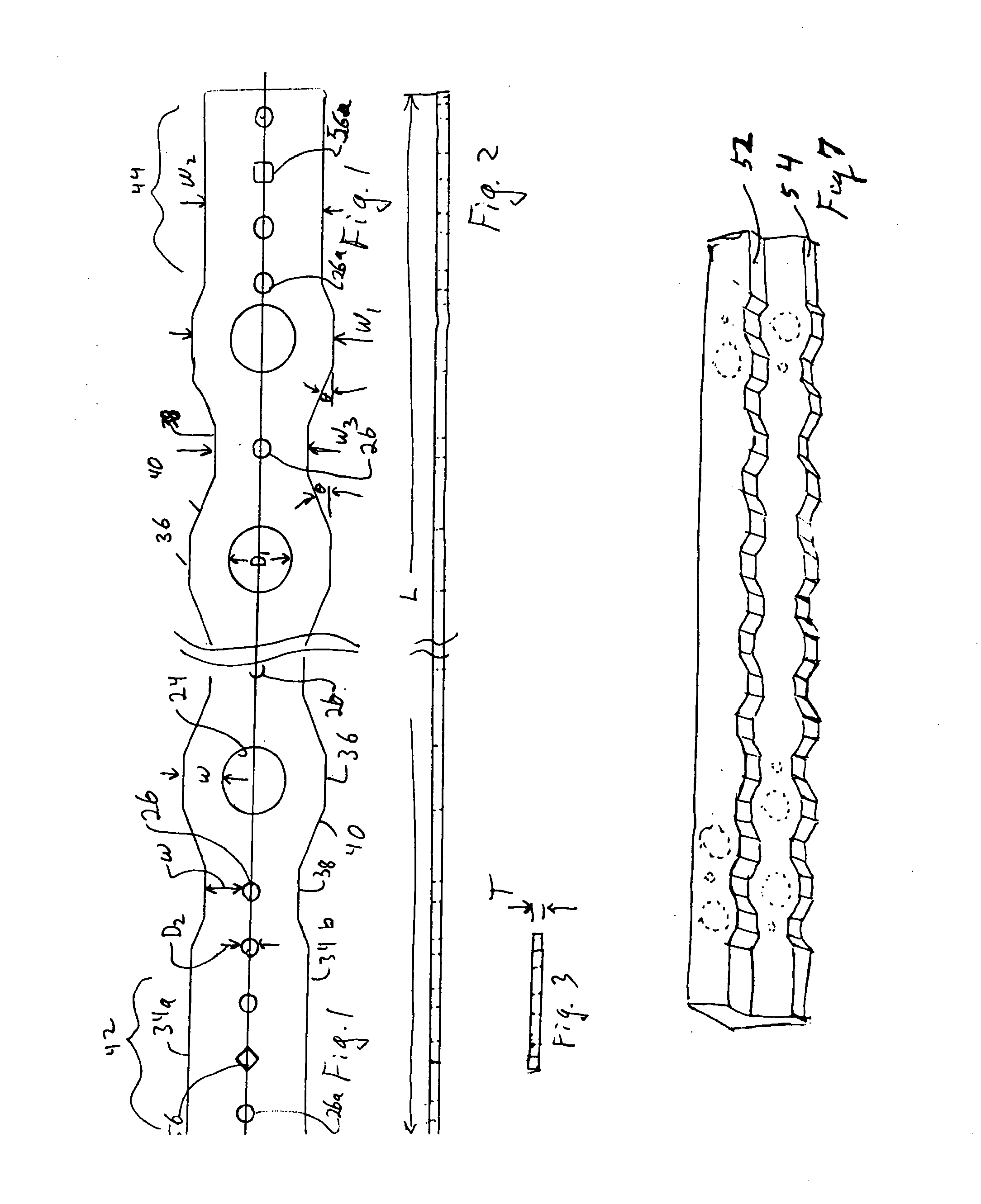

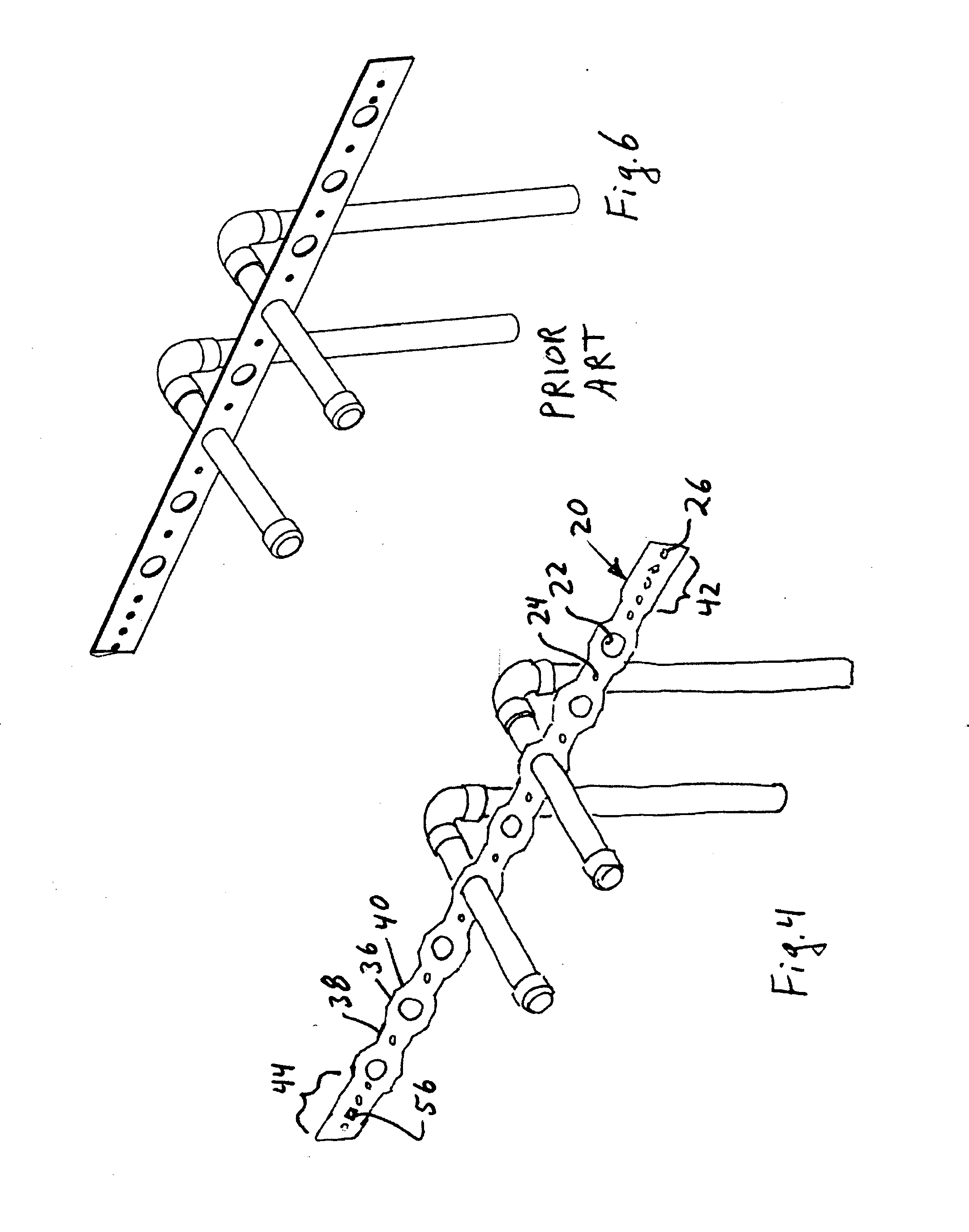

Pipe locator and support

An plumbing pipe locator and support is provided for fixing plumbing pipes in position relative to studs in a building. The pipe locator and support comprises an elongated supporting strap having upper and lower sides extending along opposing sides of a longitudinal axis. A first plurality of longitudinally aligned, larger pipe openings are interspersed with a second plurality of smaller, aligned fastener openings that extend into ends of the strap. The upper and lower sides undulate to provide a substantially uniform width between first holes and the adjacent sides and the second holes and the adjacent sides. This undulating surface can provide a strap using less material, with reduced manufacturing time, and a strap that can bend without forming creases or stress fractures.

Owner:RELIANCE WORLDWIDE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com