Device for applying a glue track to a wrapping strip of a rod-shaped product of the tobacco processing industry

A technology of shaped products and rubber imprints, which is applied to the field of devices on wrapping strips, can solve the problems of large design and high cost of filter strips, and achieve the effect of improving the connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

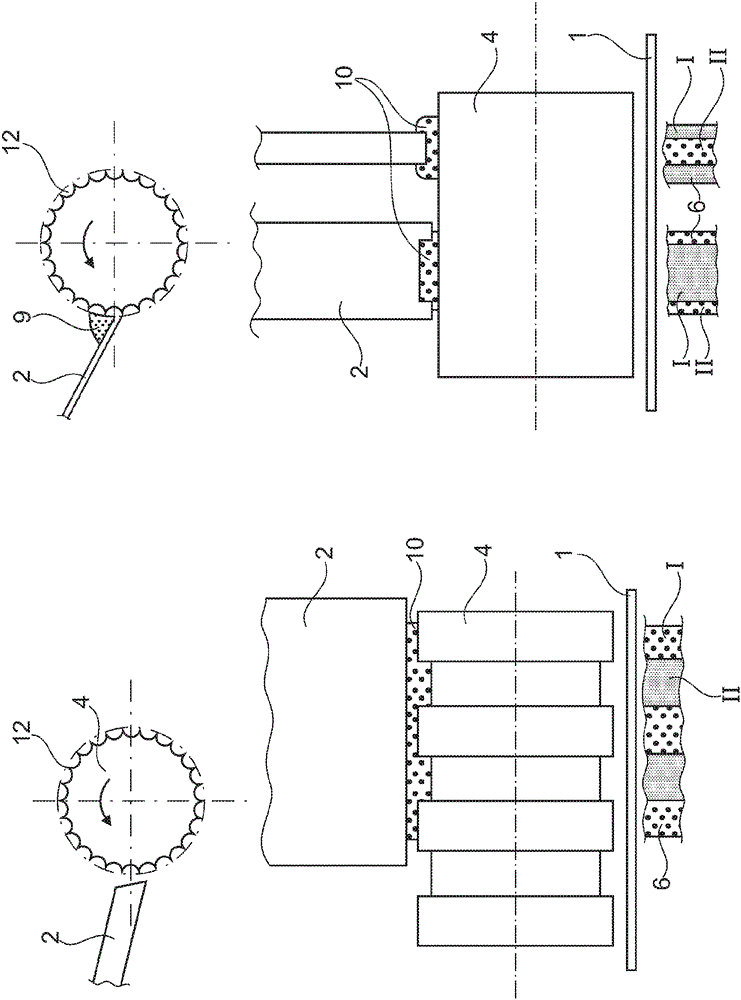

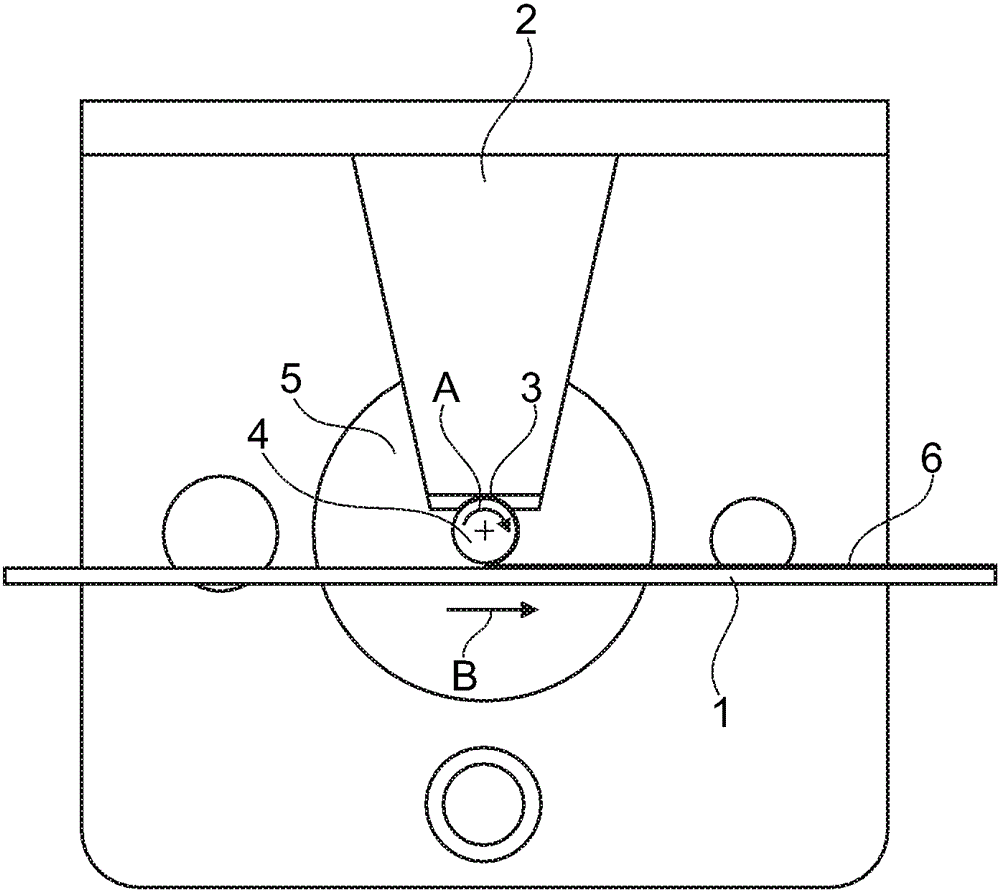

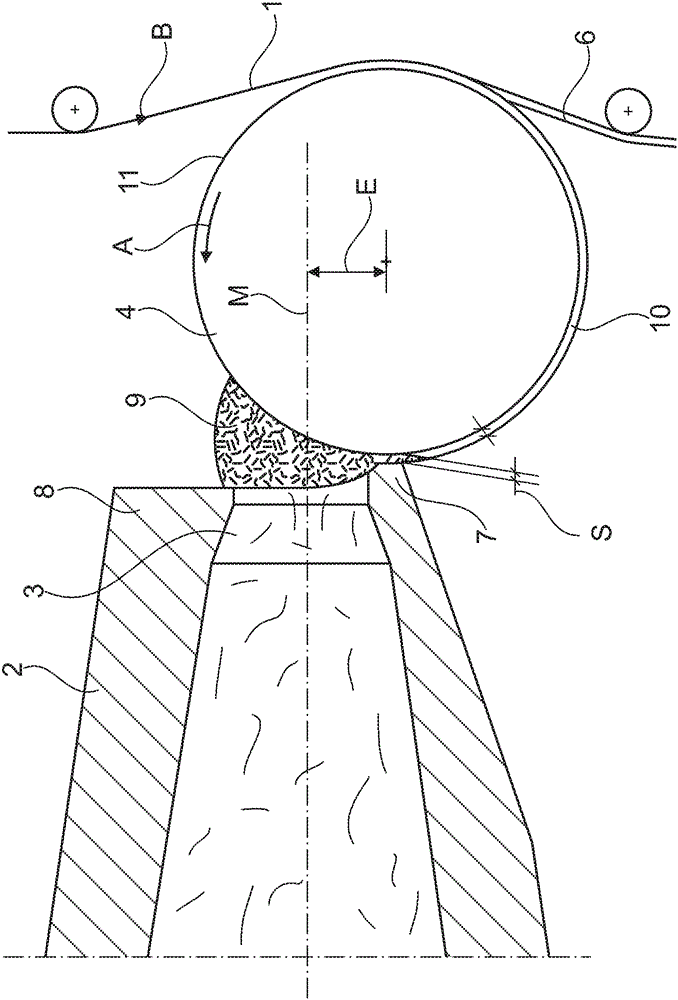

[0031] exist figure 1 In FIG. 1 there is seen a device according to the invention with a nozzle 2 held stationary relative to the machine, which nozzle has an outlet opening 3 and a rotationally driven roller 4 arranged at the outlet opening 3 . The roller 4 is in this case the end of a shaft that emerges from the electric motor 5 and is driven in rotation in the direction A of the arrow. The electric motor 5 , like the nozzle 2 , is held stationary relative to the machine and can therefore be considered stationary together with the roller 4 (extracted shaft). Furthermore, an infinite wrapping strip 1 can be seen, which is conveyed in the direction of the arrow B by means of a conveying device not shown at a conveying speed of from 100 m / min to 700 m / min, preferably at a conveying speed of 600 m / min. The roller 4 is arranged between the wrapping web 1 and the outlet opening 3 of the nozzle 2 , ie opposite the peripheral section of the roller 4 in which the roller 4 bears agai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com