Blade structure of centrifugal blower

A centrifugal blower and blade technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as noise and reduced blowing efficiency of fans, and achieve the effects of suppressing turbulence, improving inflow state, and improving inflow state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

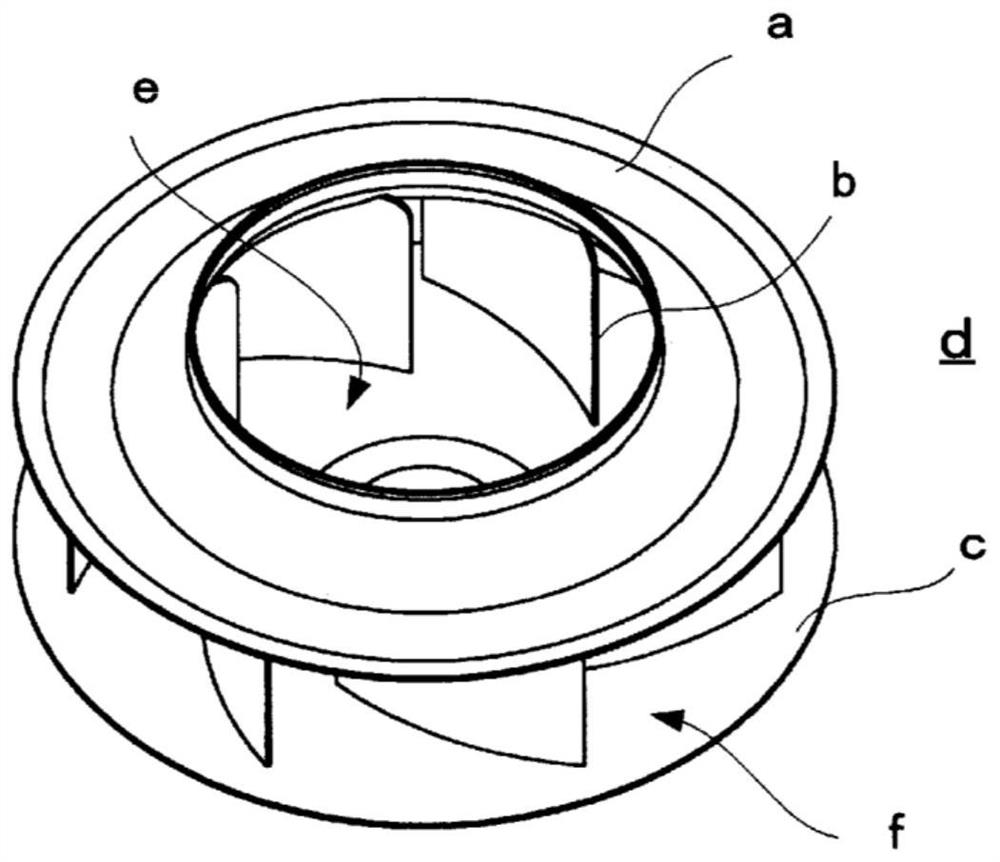

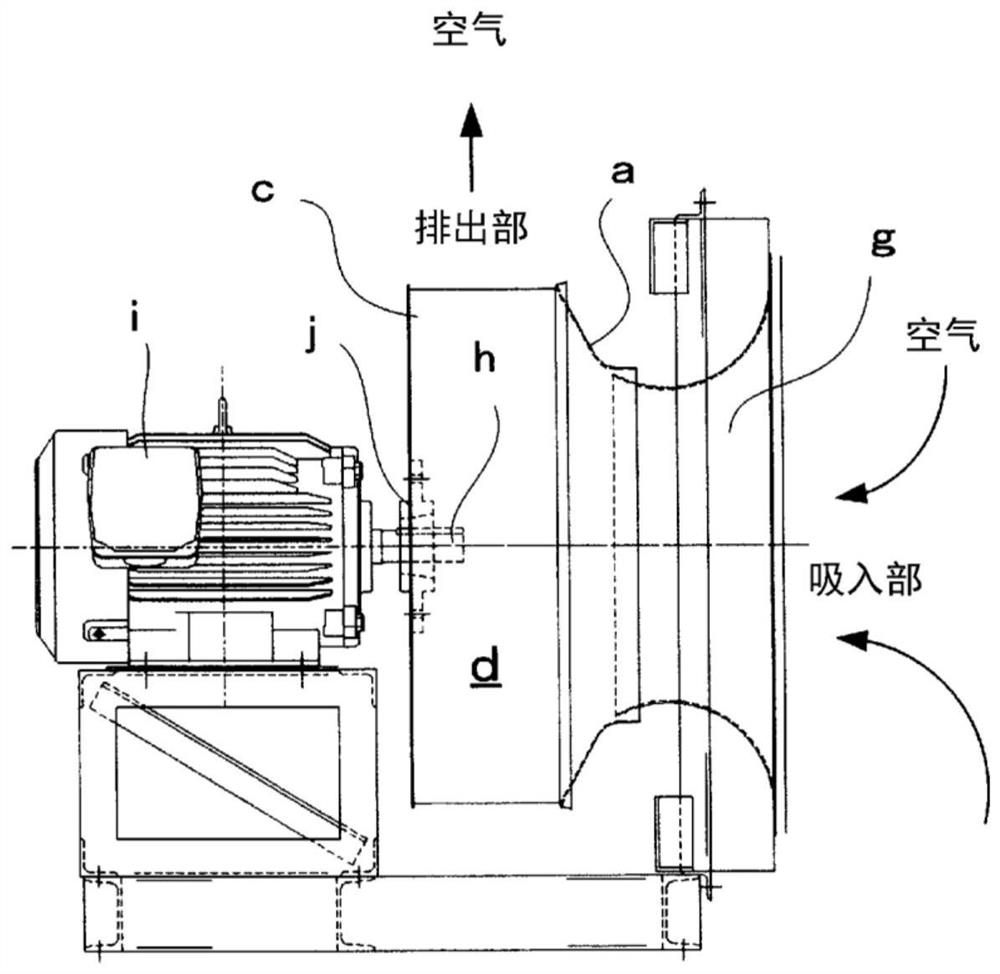

[0035] Preferred Embodiment 1 of the blade structure of the centrifugal blower of the present invention will be described, Figure 5 The impeller 4 of the centrifugal blower is the same as before figure 2 The structure as shown is arranged in the blast chamber in the air conditioner.

[0036] First, assemble from Figure 5 The blade 3 of the impeller 4 in Embodiment 1, which is combined with the fan suction port 7, will be described first.

[0037] The blades 3 of the impeller 4 are arranged obliquely at equal intervals from the suction portion 5 toward the outer peripheral discharge portion 6 between the back plate 1 and the shroud 2 .

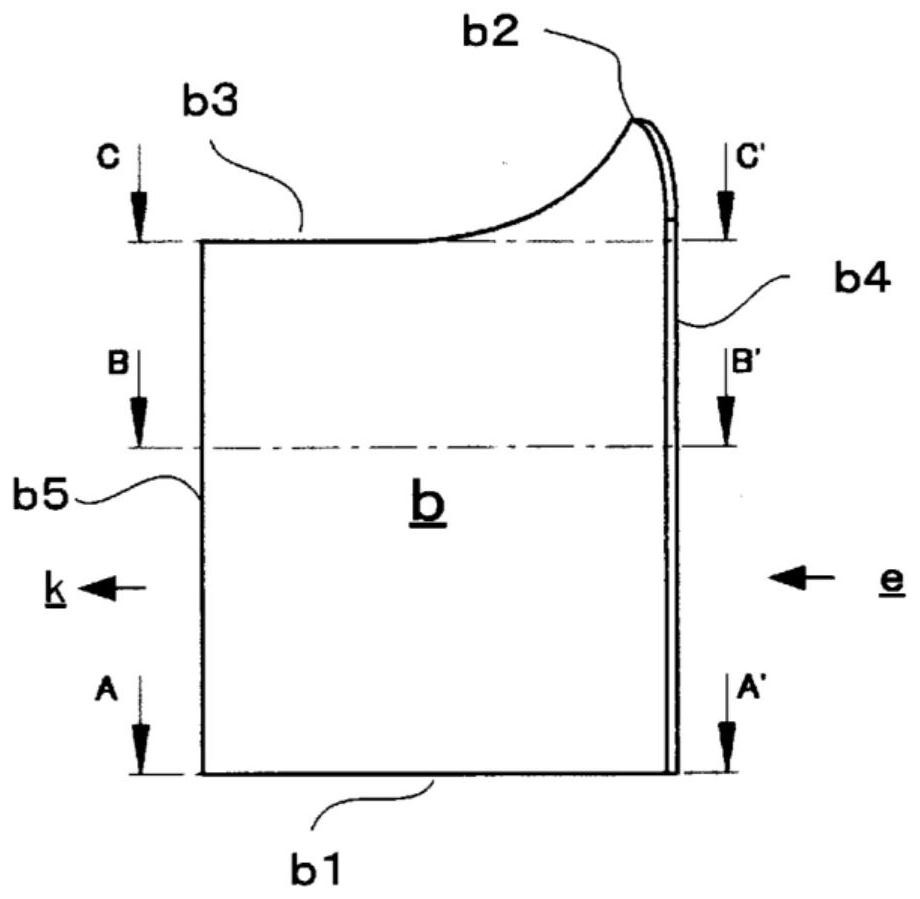

[0038] The blade lower side 31 of the blade 3 is a shape along the back plate 1, the blade upper side 33 is a shape along the inner surface of the shroud 2, and the vicinity of the suction part 5 that cuts off the air on the blade upper side 33 has a raised protrusion. shape part 332 .

[0039] And, the blade leading edge portion 32 that...

Embodiment 2

[0043] In the present invention, by adjusting the width of the belt at the center of the vertical width of the blade 3 in the impeller 4 of the centrifugal blower, the twisted shapes Y1 and Y2 near the front edge can be kept as they are, and high efficiency and low noise can be maintained. and the blade width (Z) can be easily changed. Therefore, it is possible to design and manufacture a centrifugal fan corresponding to the designed air volume.

[0044] Here, refer to Figure 9 and Figure 10 Example 2 in which the vertical width of the impeller 4' is changed to a blade width corresponding to the blowing volume will be described.

[0045] Figure 9 It is the perspective view of the impeller 4' of embodiment 2, as Figure 10 As shown, the twisted shapes Y1 and Y2 near the front edge of the blade 3 are the same as those in Example 1, and compared with the conventional partially cylindrical blade, the blowing efficiency is improved and the noise is also reduced. That is, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com