Air table for conveying sheet material and conveyer with the same

A pneumatic workbench, thin-plate technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of large ventilation resistance, small air flow, small floating amount, etc., to suppress air turbulence and achieve high reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

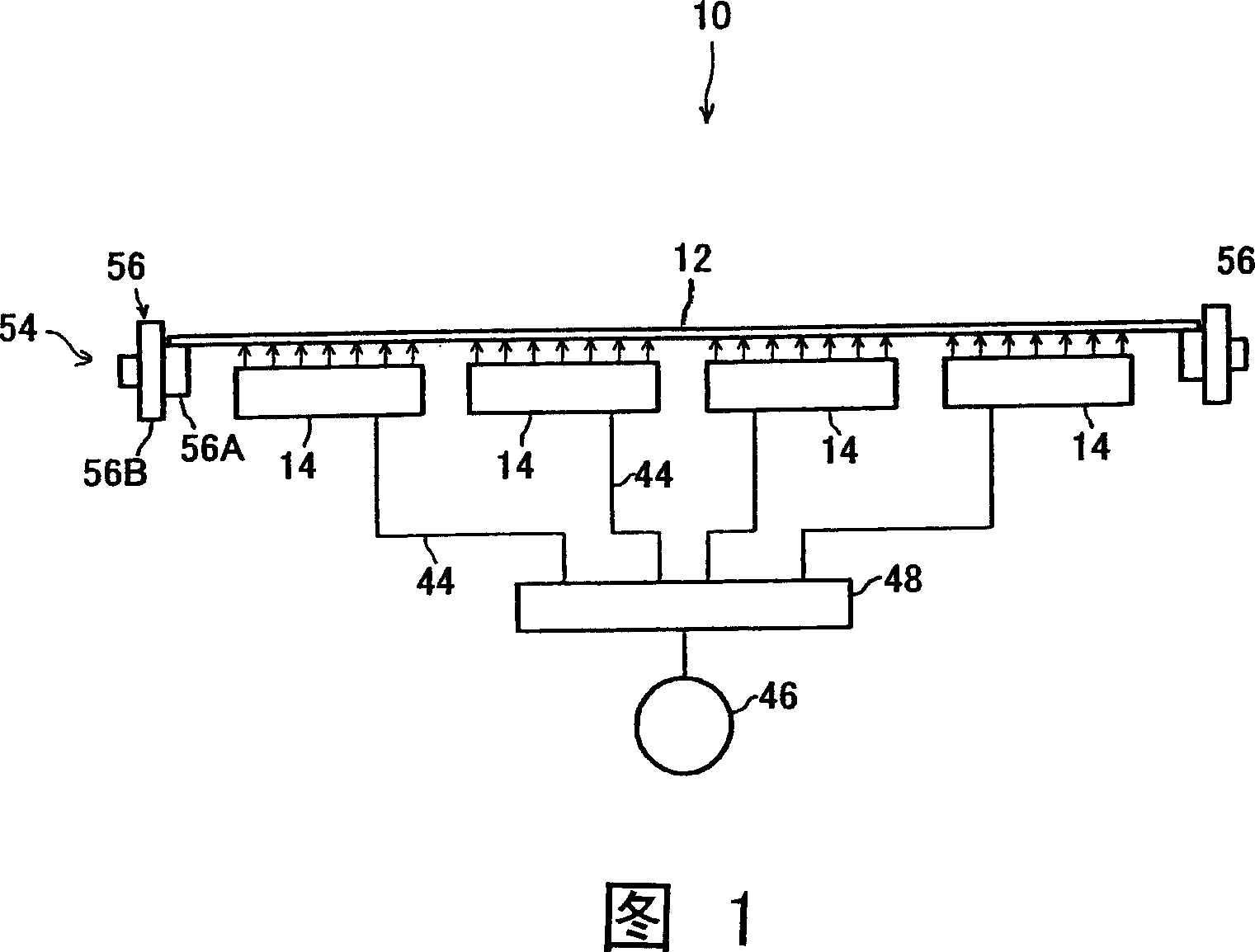

[0066] The sheet-shaped material conveying apparatus 10 is constructed as in the first embodiment described above, and the glass substrate 12 is conveyed in the clean room. The specific conditions are as follows.

[0067] Dimensions of the glass substrate 12: W1500mm×L1800mm×t0.7mm

[0068] The flow velocity of the downdraft in the clean room: about 500mm / sec

[0069] External dimensions of the pneumatic table 14 for conveying sheet-shaped materials: W300mm×L700mm×H40mm

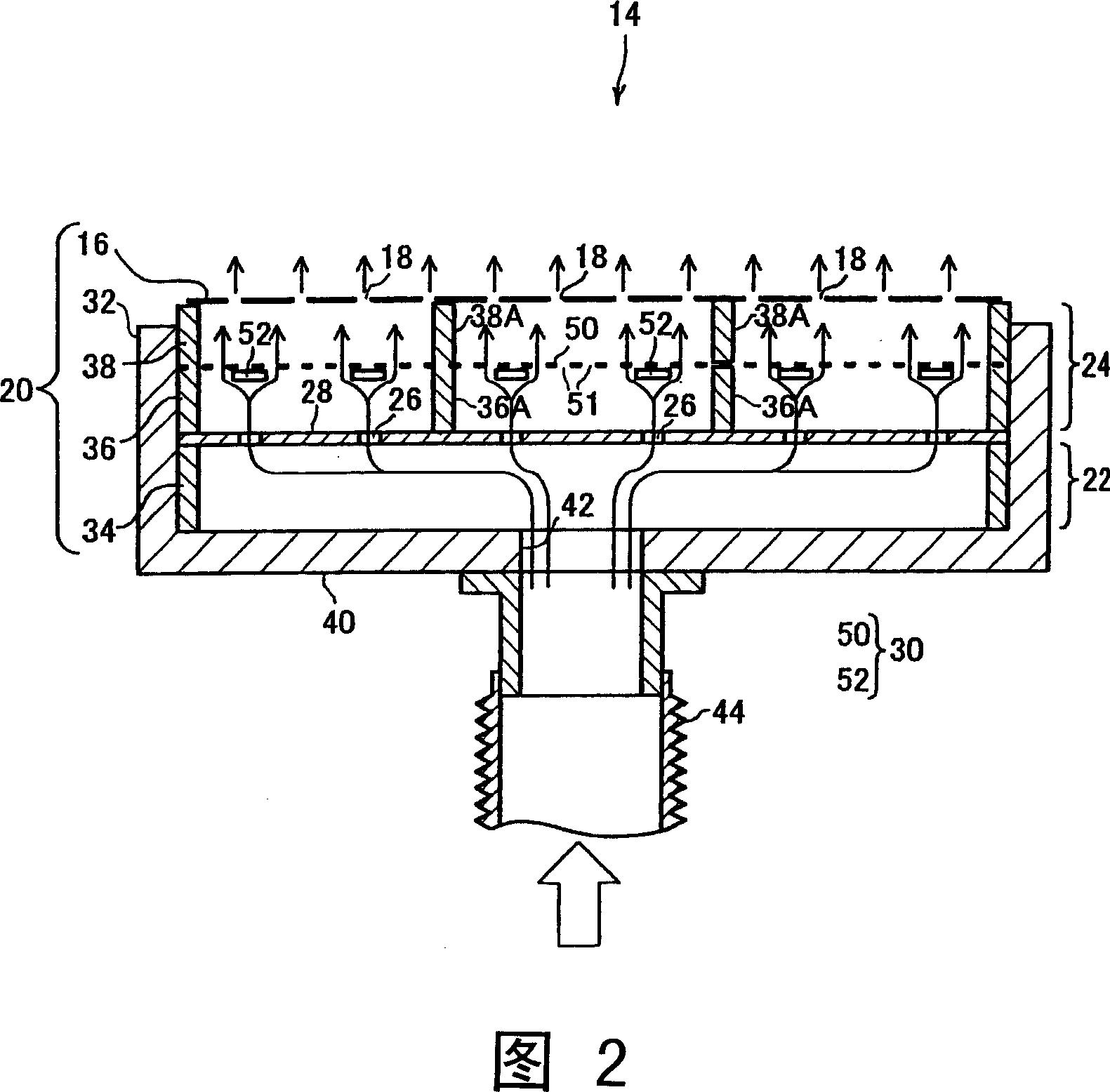

[0070] Divided grid size of the second frame 36 and the third frame 38: 90mm×25mm

[0071] The number of divided grids of the second frame 36 and the third frame 38: 3 columns×23 rows

[0072] The size and spacing of the middle air hole 26: φ3.5×P15mm

[0073] Opening area ratio of the partition wall portion 28: 4.2%

[0074] The material of the uniform opening part 50 of the airflow uniform distribution attenuator 30: metal mesh

[0075] Air flow uniform distribution Attenuator 30 opening area ratio: 3...

Embodiment 2

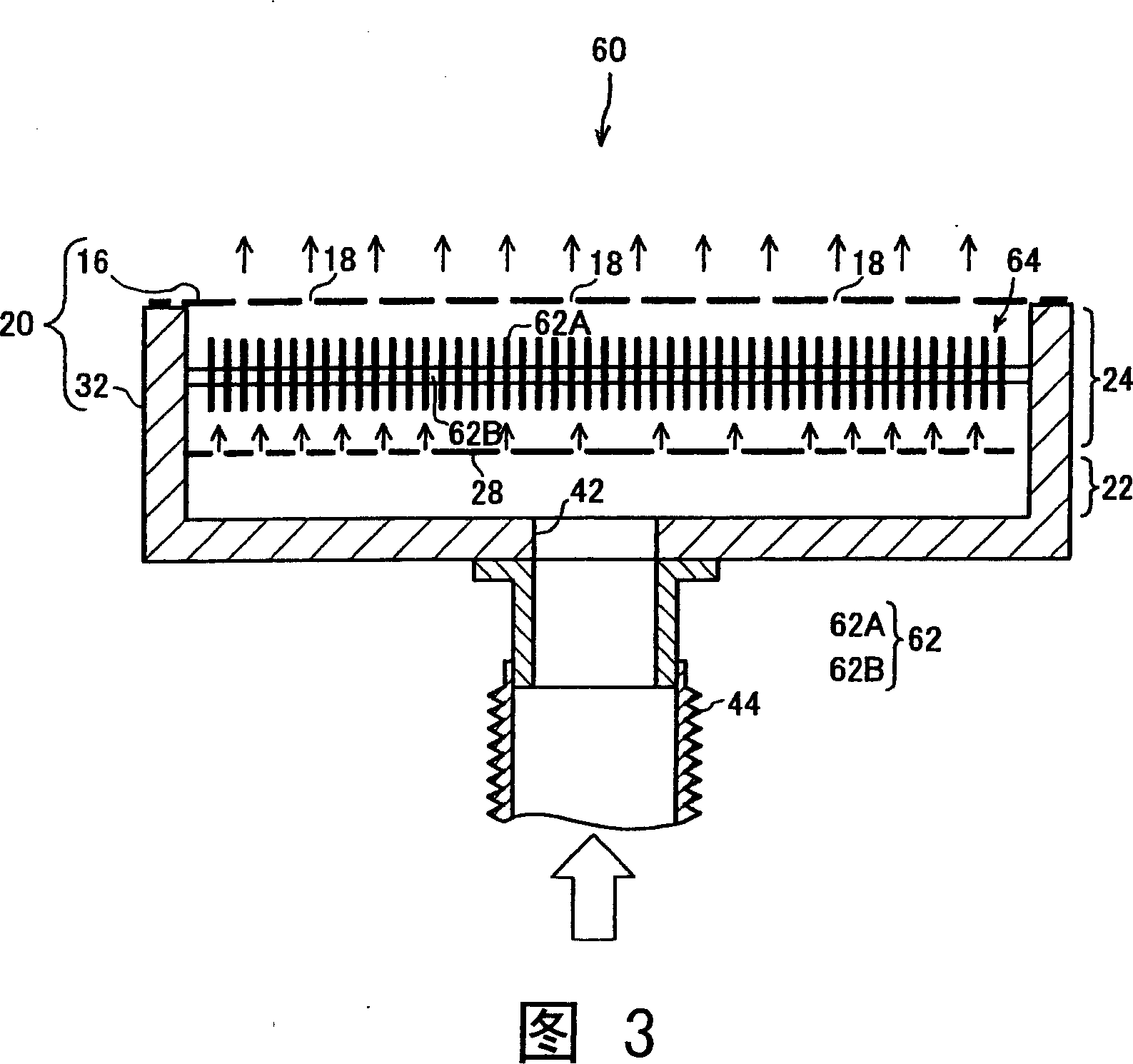

[0081] The sheet-shaped material conveying apparatus 10 is constructed as in the second embodiment described above, and the glass substrate 12 is conveyed in the clean room. The specific conditions are as follows.

[0082] Dimensions of the pneumatic table 60 for conveying thin plate materials: W300mm×L700mm×H50mm

[0083] Material of the partition portion 28: expanded alloy

[0084] Opening area ratio of the partition wall portion 28: 65%

[0085] Dimensions of airflow uniform distribution attenuator 64: W280mm×L680mm×H22mm

[0086] Material of sheet member 62A: aluminum sheet

[0087] Thickness of the thin plate member 62A x juxtaposition pitch: T0.11mm x P22mm

[0088] In addition, the size of the glass substrate 12 , the flow velocity of the downdraft in the clean room, the material of the upper surface portion 16 of the outer wall portion 20 , and the opening area ratio are the same as those of the first embodiment.

[0089] Under the above conditions, the floating a...

Embodiment 3

[0092] The sheet-shaped material conveying apparatus 10 is constructed as in the third embodiment described above, and the glass substrate 12 is conveyed in the clean room. The specific conditions are as follows.

[0093] Dimensions of the pneumatic table 60 for conveying thin plate materials: W300mm×L700mm×H50mm

[0094] Material of the partition portion 28: expanded alloy

[0095] Opening area ratio of the partition wall portion 28: 65%

[0096] The stacking height of the uniform opening part 72 of the air flow uniform distribution attenuator 74: 18mm

[0097] Filling rate of the uniform opening part 72 of the airflow uniform distribution attenuator 74: about 3% by weight

[0098] In addition, the material of the upper surface part 16 of the outer wall part 20, the opening area ratio, the size of the glass substrate 12, and the flow velocity of the downdraft of a clean room are the same as Example 1.

[0099] Under the above conditions, the floating amount in the vicinit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com