Large-span concrete-filled steel tubes arch bridge vibration inhibiting system based on anti-seismic property

A technology of anti-seismic performance and concrete, which is applied in the direction of arch bridges, bridges, bridge forms, etc., to achieve the effects of high reliability, simple connection and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

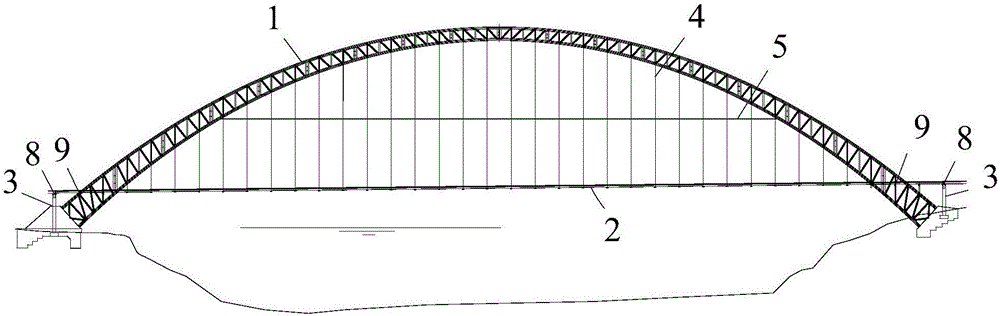

[0044] Such as figure 1 , 8 , 9, a long-span concrete-filled steel tube arch bridge vibration suppression system based on seismic performance, including the main arch 1 and deck girder 2, as well as a number of suspension cables 4 between the main arch 1 and deck girder 2, and include:

[0045] At least one anti-vibration cable 5 transversely connects all said slings 4 into an integral structure;

[0046] A plurality of longitudinal limit damping devices 8 are arranged between the bridge deck girder 2 and the correspondingly installed bridge piers 3;

[0047] Two lateral limit damping devices 9 are arranged at the positions where the two ends of the main arch 1 intersect with the deck beam 2 respectively.

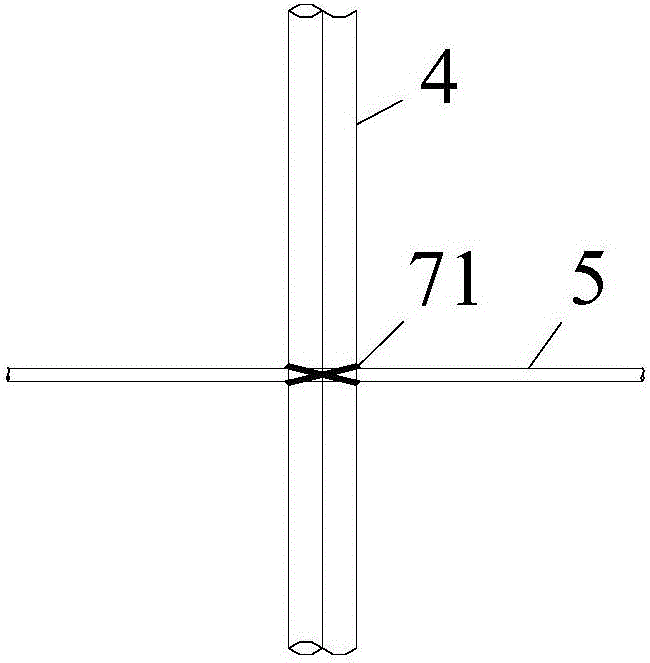

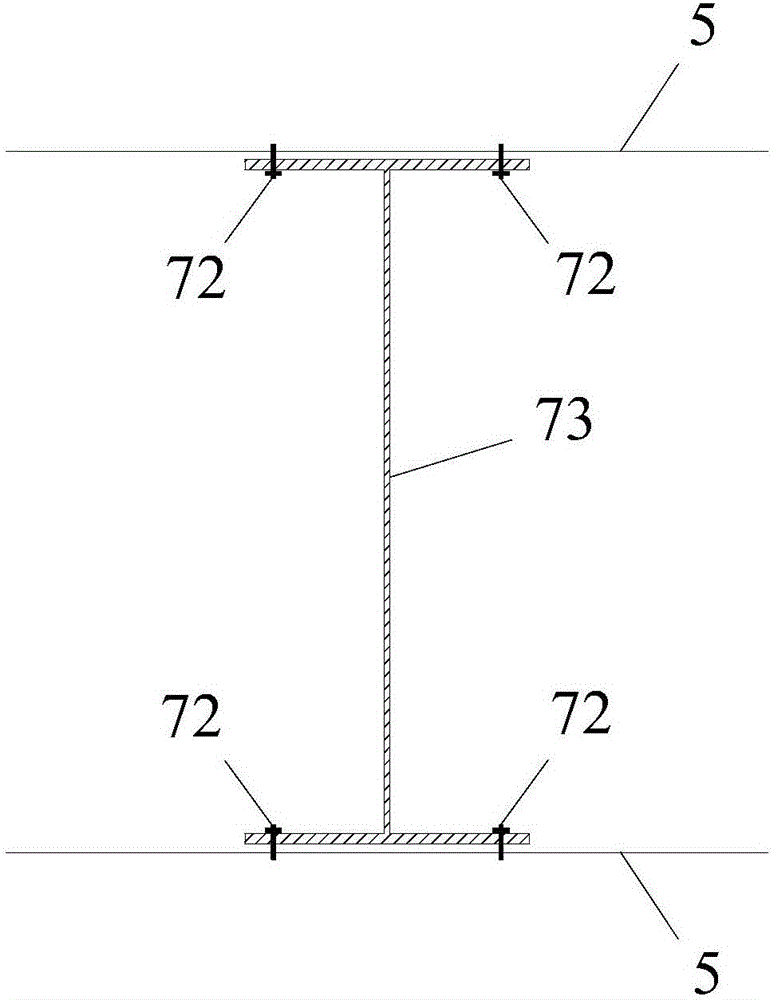

[0048] Such as figure 2 As shown, the above-mentioned anti-vibration cables 5 and all the suspension cables 4 are connected to each other through binding wires 71 . The binding wire 71 can be made of high-strength fiber plastic material, and can ensure that the anti-w...

Embodiment 2

[0061] Such as Figure 5-7 As shown, the present embodiment provides an installation method for the anti-vibration cable 5, including the following installation steps:

[0062] Step 1, set the traction cable at both ends of the anti-vibration cable 5 to pass through the reaction force frame 6 and the corresponding anchor 64;

[0063] Step 2: Install two tensioning reaction frames 6 on the steel pipe cross-links 12 at both ends of the main arch 1, pass the anti-vibration cables 5 through the reaction frames 6, and stretch the anti-vibration cables 5 to the design tension;

[0064] Step 3, anchoring and locking the anti-vibration cable 5;

[0065] Step 4, binding the anti-vibration cables 5 and each of the slings 4 into an integral structure.

[0066] By adopting such installation steps, the anti-vibration cable 5 is simple and reliable to install, and has strong operability. It has been proved by engineering application that this construction technology makes the cable suspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com