Porous floating breakwater

A breakwater and hole floating technology, which is applied in the field of porous floating breakwater, can solve the problems that the floating breakwater structure is subject to strong wave force, the safety of the structure itself is difficult to guarantee, and the water circulation in the shelter area is limited, so as to achieve the development and utilization of coastal resources and the environment. Protection promotion, large social and economic benefits, and the effect of reducing siltation in the harbor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

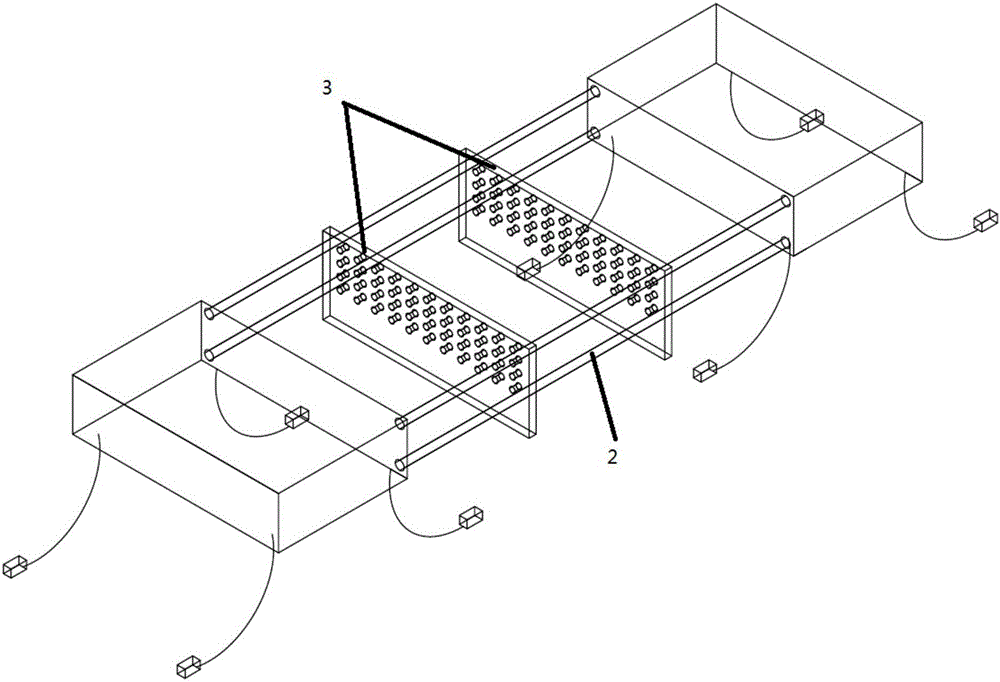

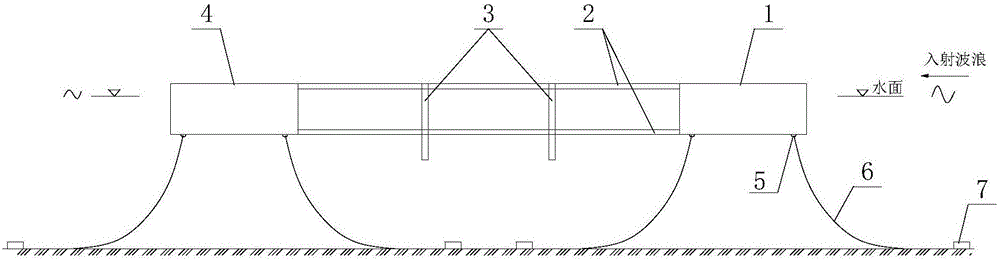

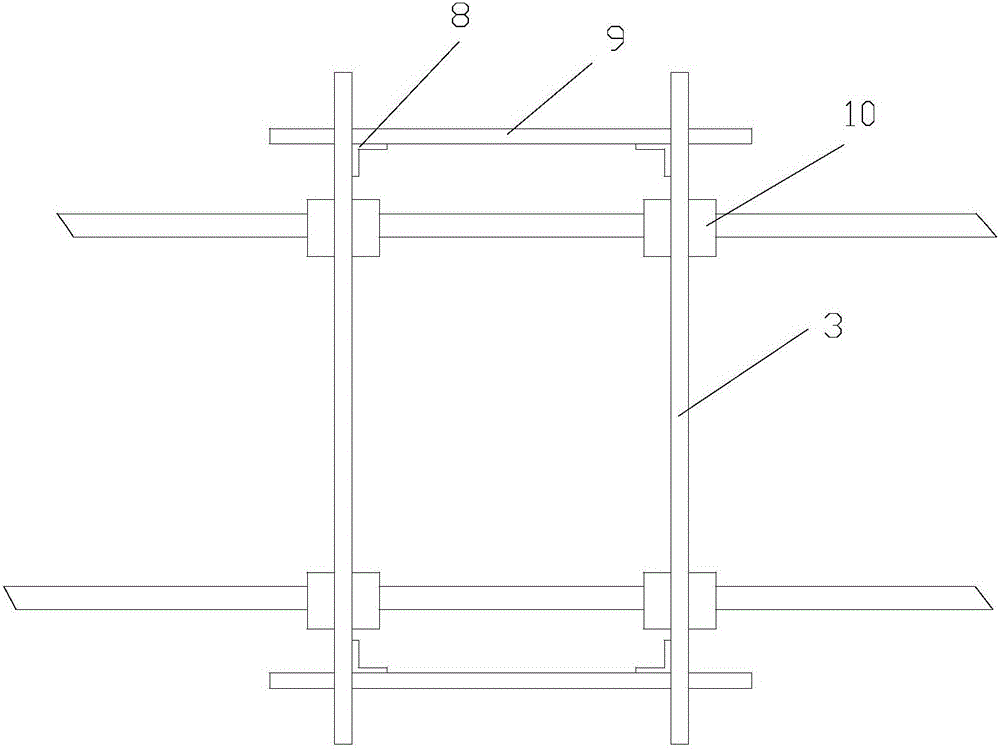

[0043] Such as figure 1 and figure 2 As shown, a porous floating breakwater of the present invention comprises several breakwater units connected in sequence, adjacent breakwater units can be flexibly connected by hinges, and the breakwater unit comprises a first pontoon 1 and a second pontoon 4 , connecting rod 2 and two layers of vertical plates 3, the first buoyant tank 1 and the second buoyant tank 4 are rigidly connected by connecting rod 2, the first buoyant tank 1 and the second buoyant tank 4 are all passed through the guide anchor holes 5 and The anchor chain 6 is connected with the mooring counterweight 7 for mooring, and the two vertical plates 3 are fixedly installed on the connecting rod 2, and several water holes are arranged on the two vertical plates 3, and the water holes of the vertical plates The porosity is 9% to 11%. When there are too many openings on the vertical plate 3, the propagation of waves cannot be well blocked, and the energy dissipation effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com