Tensile type pile soil deformation coordinator

A coordinator, pile-soil technology, applied in the direction of foundation structure test, construction, foundation structure engineering, etc., can solve the problem of inaccurate design bearing ratio, shorten the construction period, save the number of piles, improve safety and reliability degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

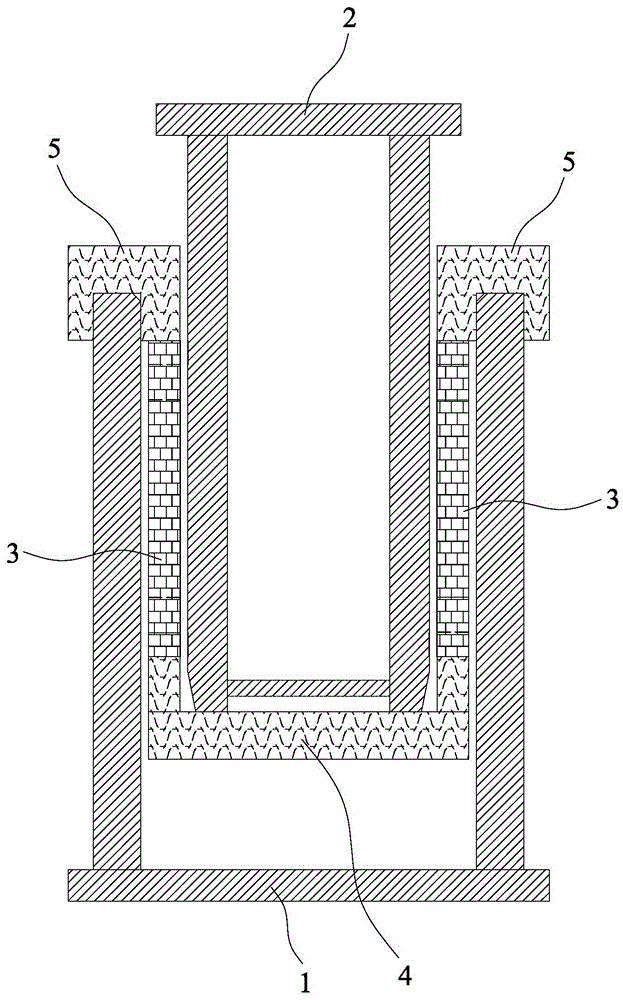

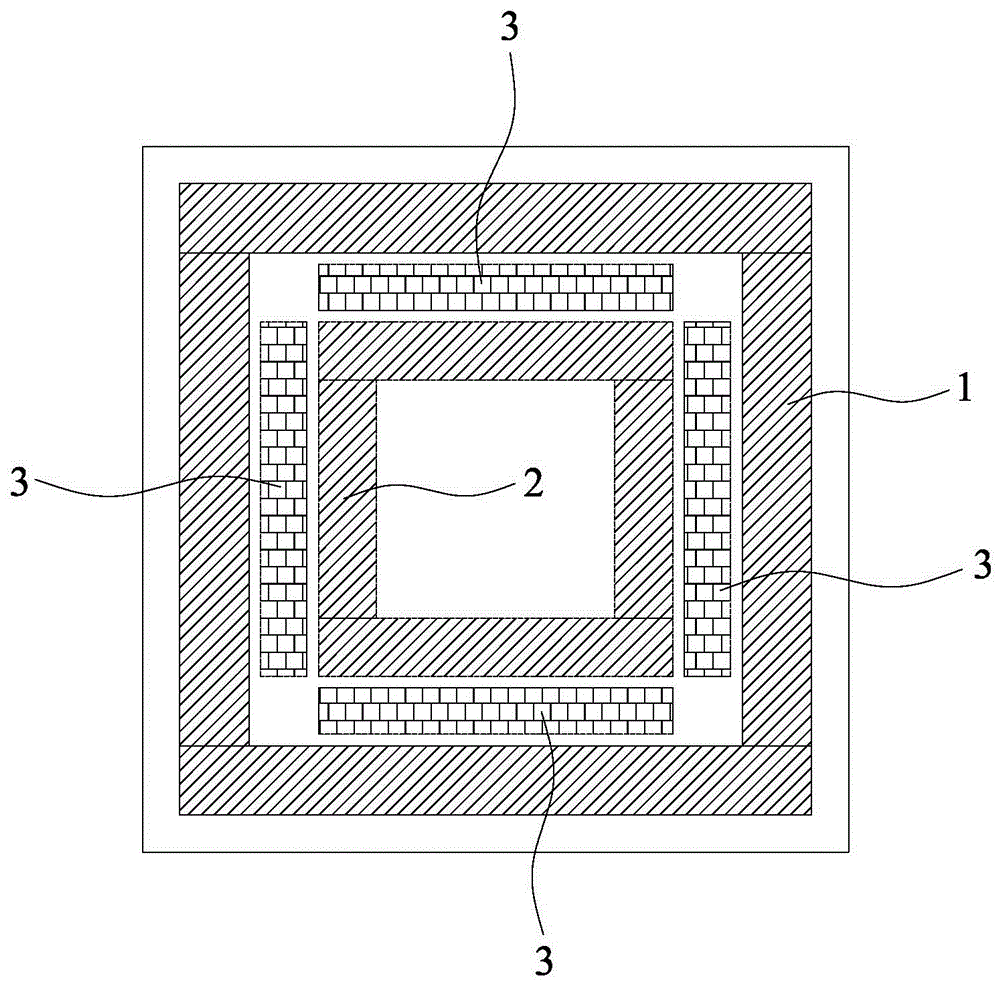

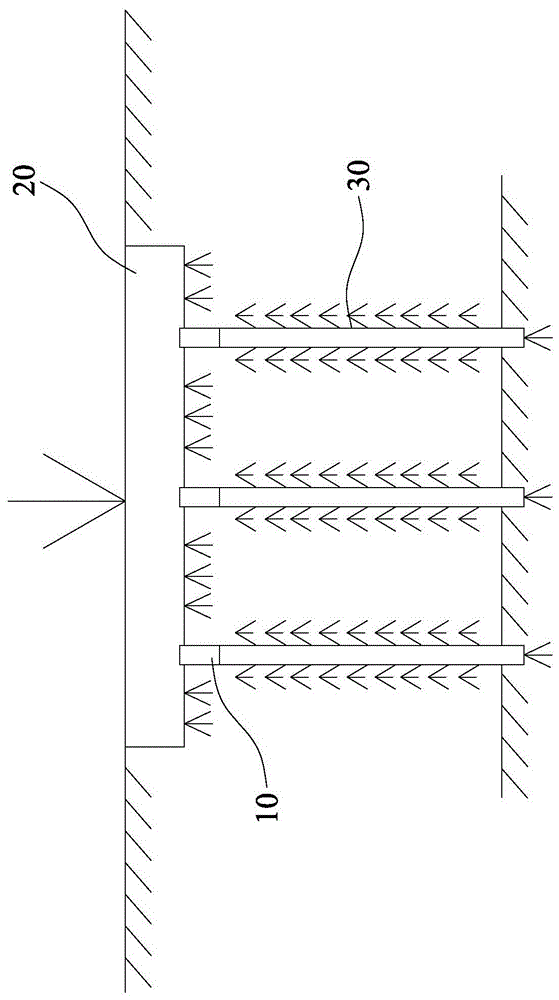

[0012] Such as figure 1 , figure 2 As shown, the present invention is a tension-type pile-soil deformation coordinator, including an outer cylinder 1, a push rod 2, a ductile plate 3, a force transmission end plate 4, and a force transmission pendant 5.

[0013] The outer cylinder 1 is a cylindrical member with one end open, the force transmission hanger 5 is fastened to the open port of the outer cylinder 1, the force transmission end plate 4 is nested in the inner cavity of the outer cylinder 1, and the ductile plate 3 is sleeved on the outside. The inner cavity of the cylinder 1 and the two ends of the ductile plate 3 are respectively connected to the inner bottom surface of the force transmission hanger 5 and the force transmission end plate 4; the push rod 2 passes through the through hole in the middle of the force transmission hanger 5 and penetrates into the outer cylinder 1 Inside, the penetrating end of the push rod 2 leans against the force transmission end plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com