Metal connecting frame

A metal connection and horizontal frame technology, applied in the direction of ladders, buildings, building structures, etc., can solve the problems of increased labor, increased use costs, and inability to use elevators, etc., to achieve the effect of saving transportation, reducing costs, and convenient storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

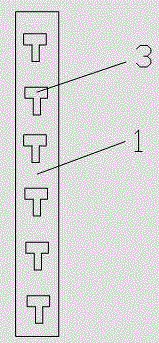

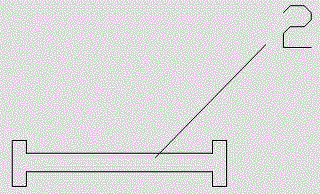

[0013] Such as Figure 1~3 The shown metal connecting frame includes two vertical frames 1 and several horizontal frames 2, the vertical frame 1 is evenly opened with fixing holes 3, the fixing holes 3 are T-shaped, and the horizontal frames 2 are cylindrical, The two ends are rectangular, and the area of the square is larger than the cross section of the cylinder; the horizontal frame 2 is fixed in the fixing hole 3, and the fixing hole 3 is T-shaped, and the area of the horizontal side is larger than that of the rectangular end surface of the horizontal frame 2. Area, the width of its longitudinal side is the same as the diameter of the cylindrical section of the horizontal frame 2.

[0014] Further, another metal connection frame, such as Figure 1~4 As shown, it includes two vertical frames 1 and several horizontal frames 2. The vertical frame 1 is evenly opened with fixing holes 3, the fixing holes 3 are T-shaped, the horizontal frames 2 are cylindrical, and the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com