Method of determining drilling depth in real time according to operation parameters of hydraulic drilling rig

A technology for hydraulic drilling rigs and operating parameters, which is applied in the field of rockburst prevention and control, gas drainage, and water control in coal mines, can solve problems such as unreliable results, time-consuming and labor-intensive, etc. effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

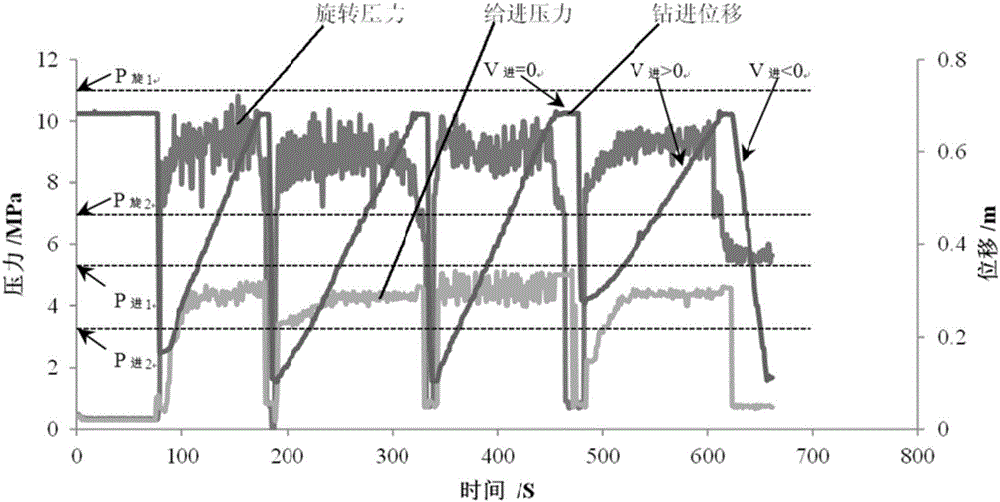

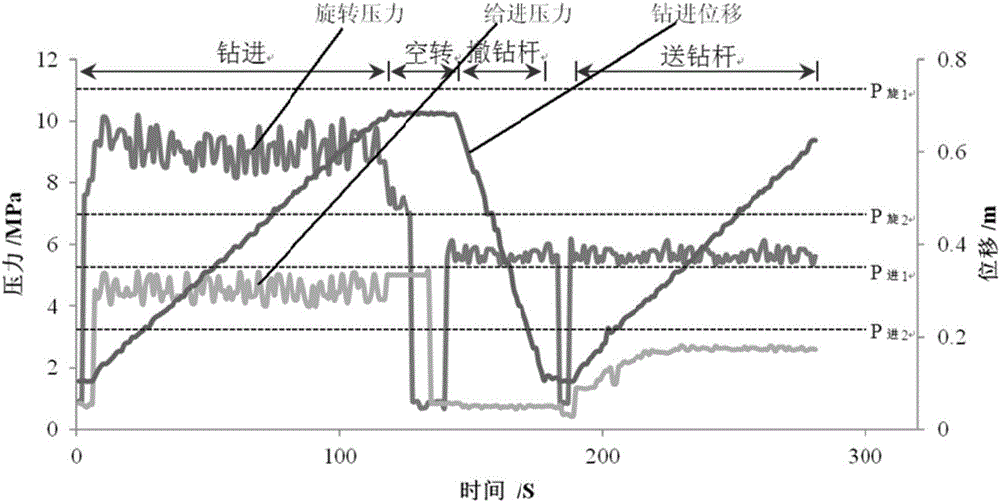

[0066] Connect the pressure transmitter in series to the input oil circuit of the rotary motor of the hydraulic drilling rig to measure the rotation pressure of the drilling rig in real time; connect the pressure transmitter in series to the input oil circuit of the feed cylinder of the hydraulic drilling rig to measure the feed pressure of the drilling rig in real time; The rate of penetration of the drill pipe is tested using a stay-wire displacement sensor. By monitoring the drilling process of 1-2 boreholes, using figure 2 Determine the characteristic values of rotational pressure, feed pressure and rate of penetration.

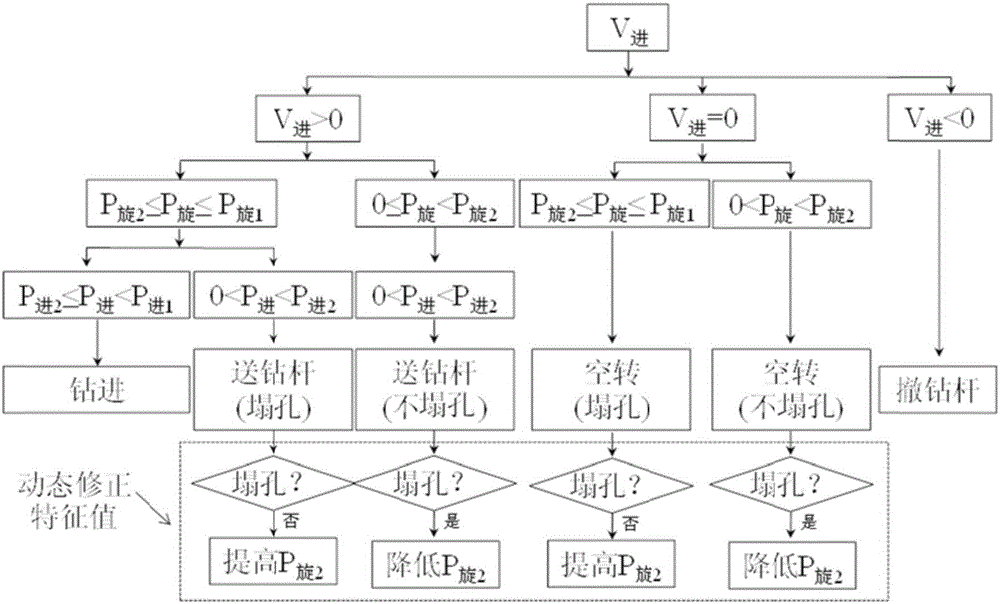

[0067] The running state of the drilling rig is judged by the relationship between the rotation pressure, the feed pressure and the feed rate and their eigenvalues. In particular, when there is a collapsed hole, the rotation pressure will change. At this time, the rotation pressure when feeding the drill pipe and drilling is relatively close, and it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com