Adjustable camshaft

A camshaft, adjustable technology for cams, belts/chains/gears, engine components, etc. to solve manufacturing errors, rotor jams, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

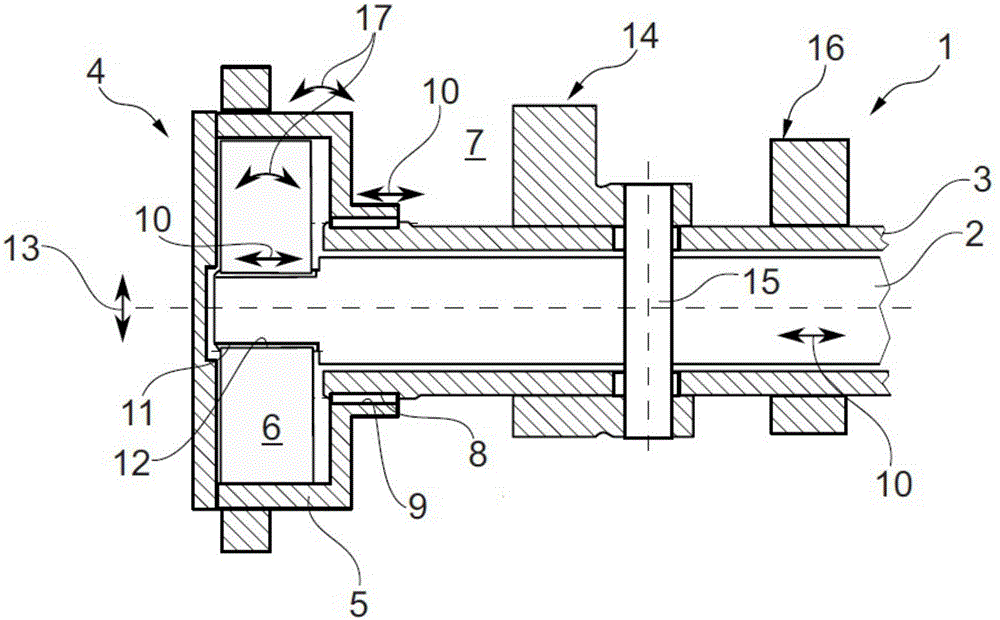

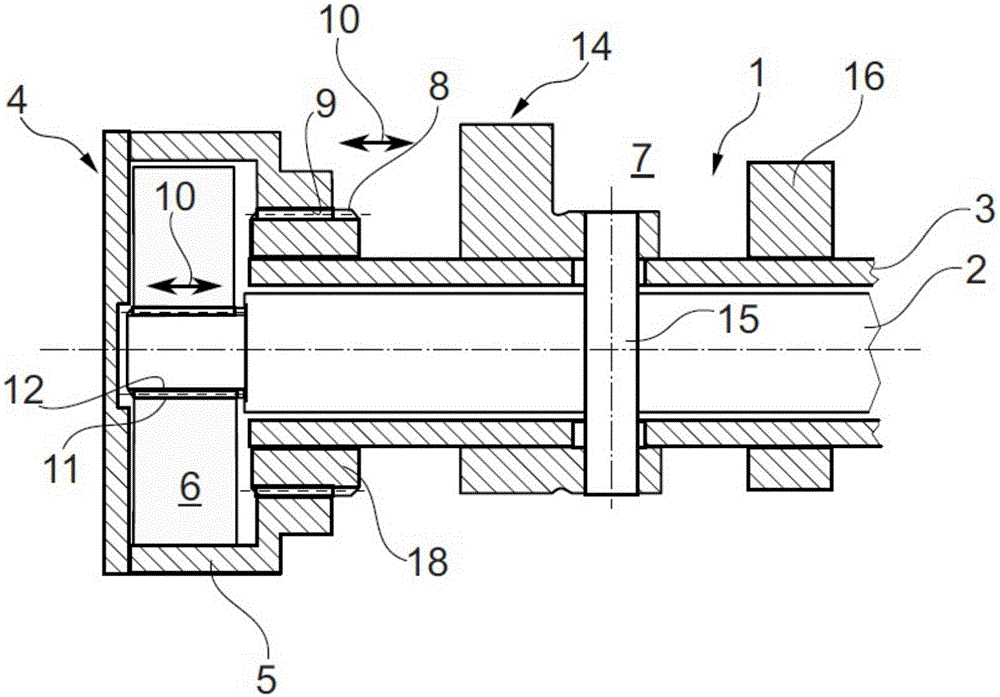

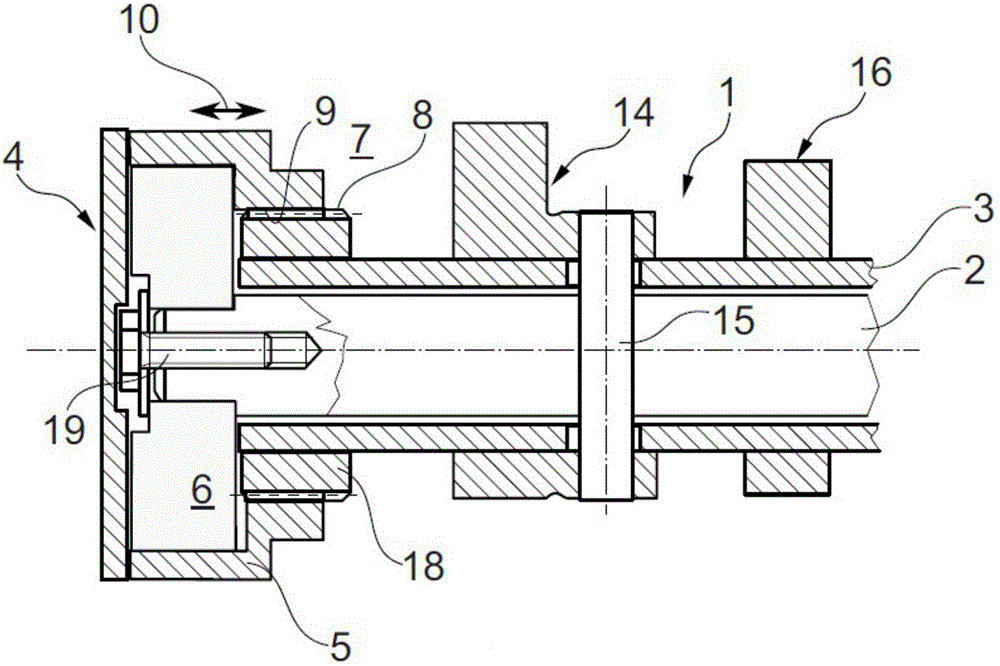

[0021] correspond Figure 1 to Figure 5 , the camshaft 1 according to the invention comprises an inner shaft 2 and an outer shaft arranged coaxially with the inner shaft 2 . The adjustment of the inner shaft 2 relative to the outer shaft 3 takes place in this case by means of a phase shifter 4, the stator 5 of which is connected to the outer shaft 3 in a rotatably fixed manner, and the The rotor 6 is connected to the inner shaft 2 in a rotationally fixed manner. Such camshafts 1 are commonly used in internal combustion engines 7 , for example in motor vehicles, in order to influence the valve opening times.

[0022] In the case of the camshafts known hitherto from the prior art, the inner shaft 2 is connected in a fixed manner to the rotor 6 and the outer shaft 3 is connected in a fixed manner to the stator 5 of the phase shifter 4, wherein the rotor 6 is even opposite A small tilted position with respect to the inner shaft 2 would lead to jamming of the rotor 6 relative to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com