A multi-sensor heating network leakage early warning monitoring system

An early warning monitoring and multi-sensor technology, applied in the pipeline system, by measuring the increase and deceleration rate of the fluid, and using the liquid/vacuum degree for liquid tightness measurement, etc., can solve the problem of not being able to detect the leakage state of the heating network and the heating network in time. Leakage early warning monitoring methods are single, monitoring equipment stays in the middle, etc., to achieve the effects of high leakage early warning monitoring accuracy, convenient system installation, and avoiding false alarms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

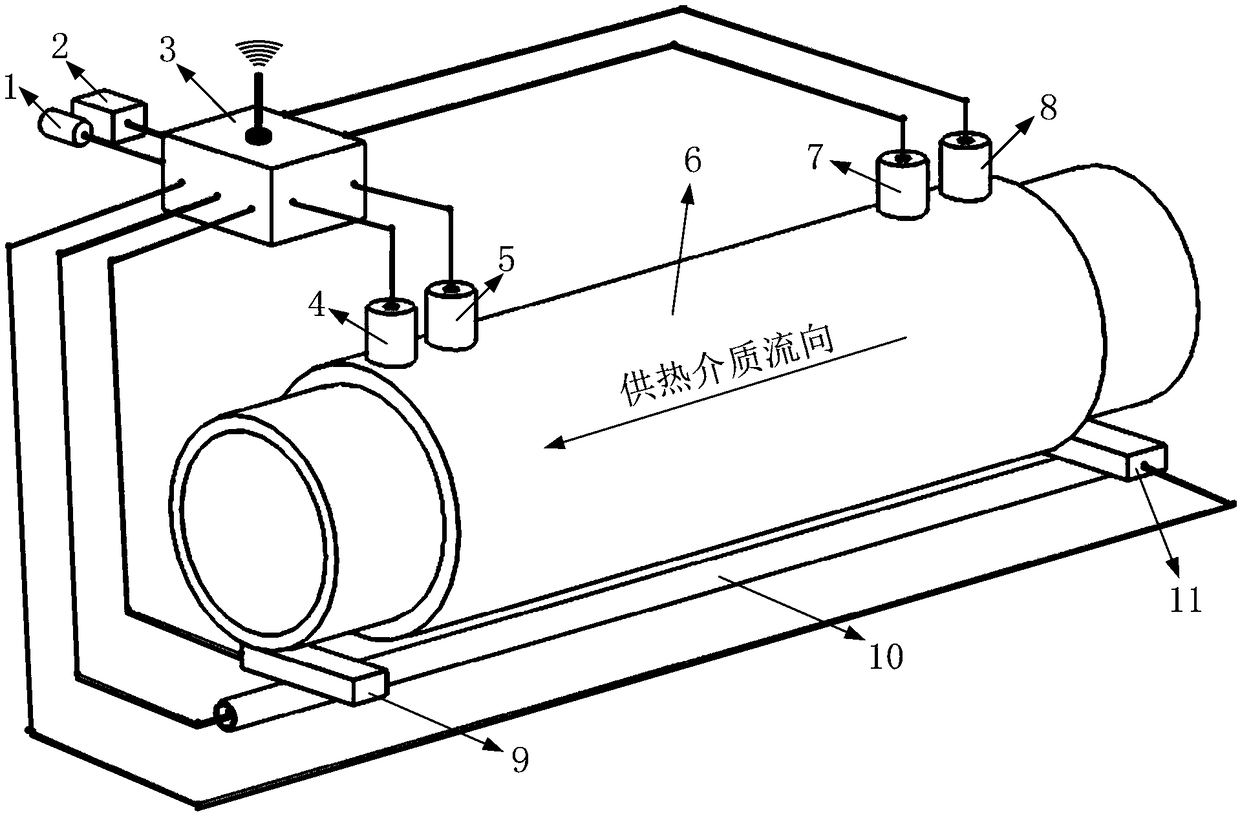

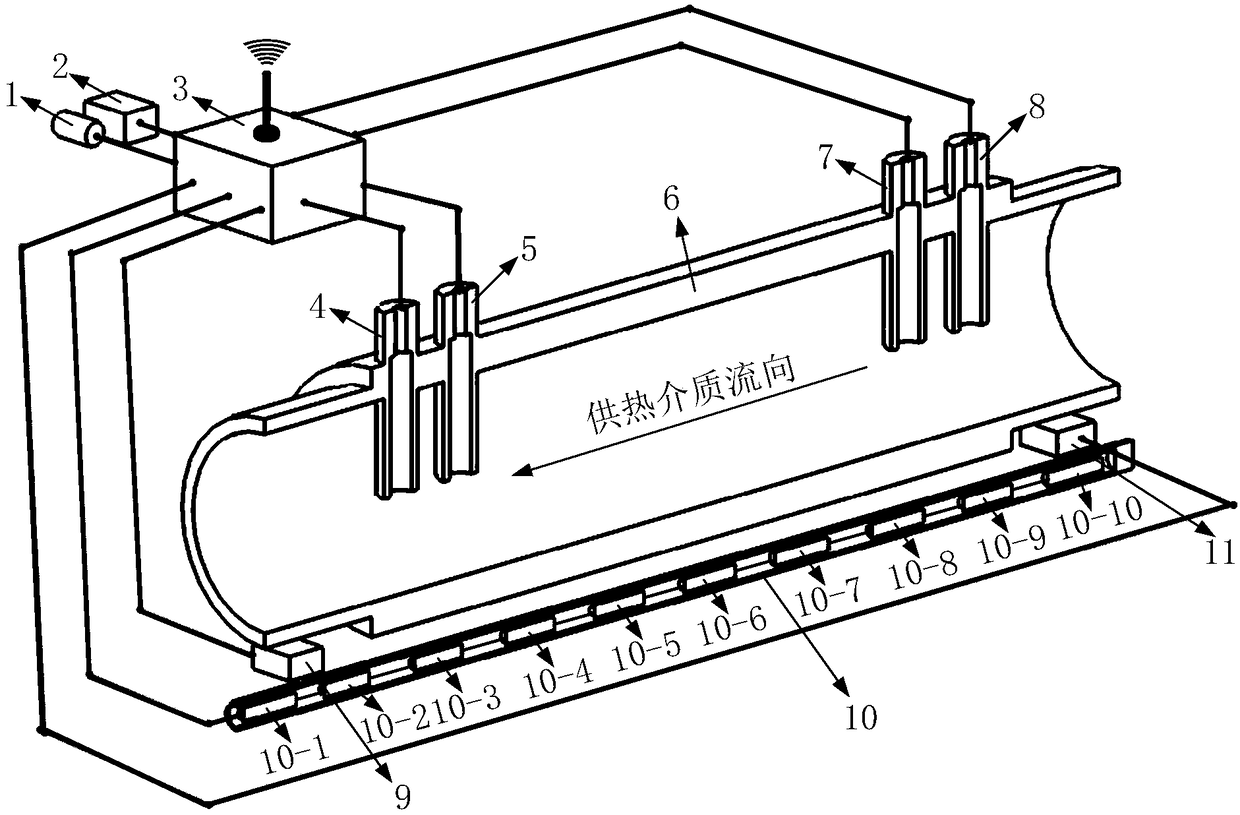

[0022] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0023] Such as figure 1 As shown, a multi-sensor heating network leakage early warning monitoring system according to the present invention includes a reference temperature sensor 1, a reference conductivity sensor 2, a pipeline leakage early warning monitor 3, an outlet flow sensor 4, an outlet pressure sensor 5, and an inlet pressure sensor. 7. Inlet flow sensor 8, outlet conductance sensor 9, pipeline temperature monitoring unit 10 and inlet conductance sensor 11; wherein, the reference temperature sensor 1 and reference conductance sensor 2 are placed near the heating pipeline 6, and the monitoring parameters are not affected by the supply The impact of the hot pipeline 6, the pipeline leakage early warning monitor 3 is buried directly above the heating pipeline 6, and the outlet flow sensor 4 and the outlet pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com