Composite multi-curved trough-type solar concentrating collector with automatic defrosting function

A trough-type solar energy and multi-curved surface technology, which is applied in the field of solar energy concentration and heat utilization, can solve the problems of affecting the reflection effect, the center of gravity does not coincide, and the effect of affecting the light concentration efficiency of the concentrator, and achieves the effect of low tracking accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

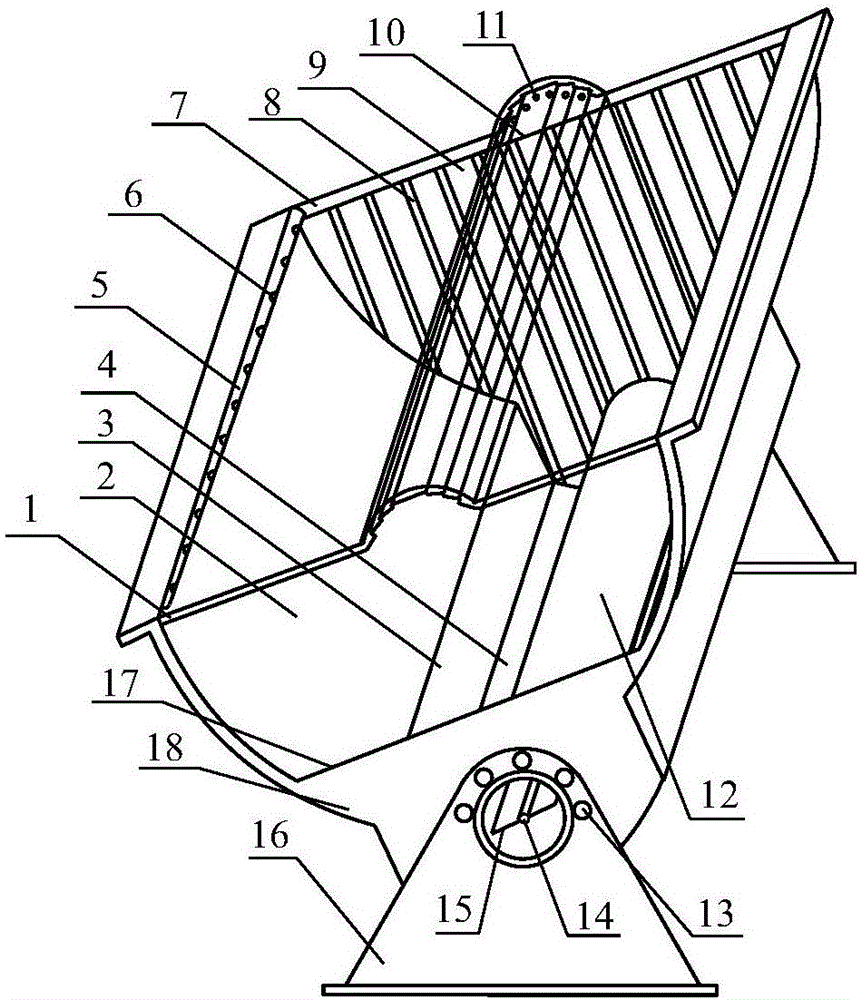

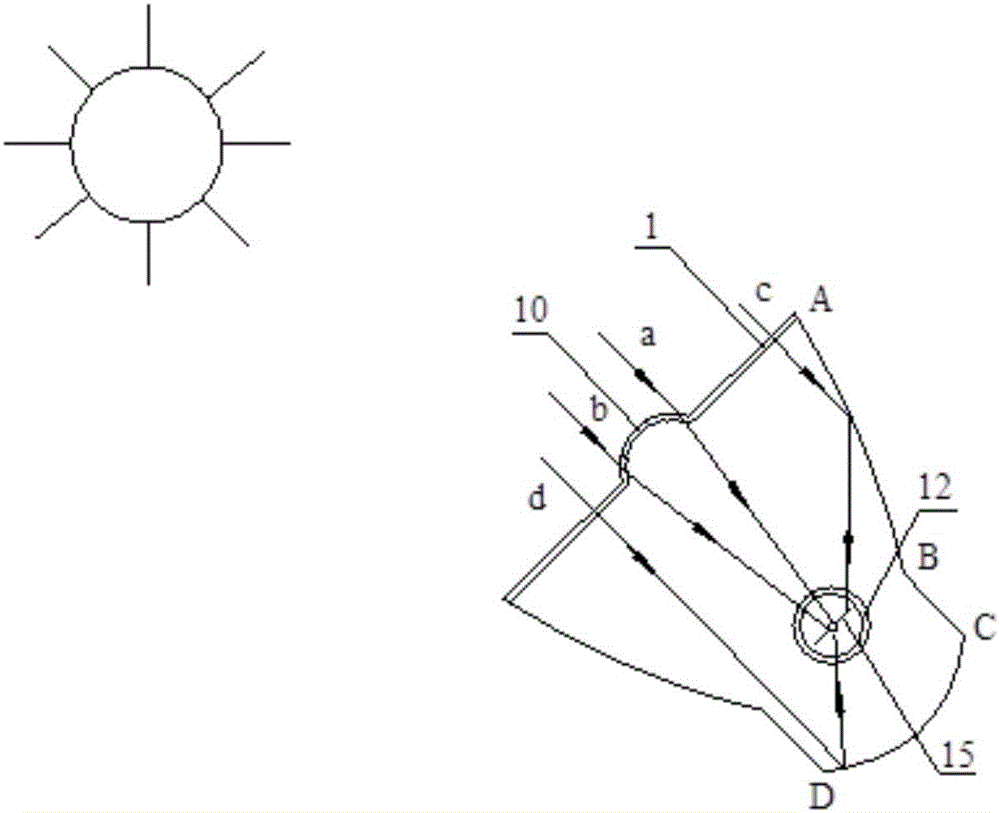

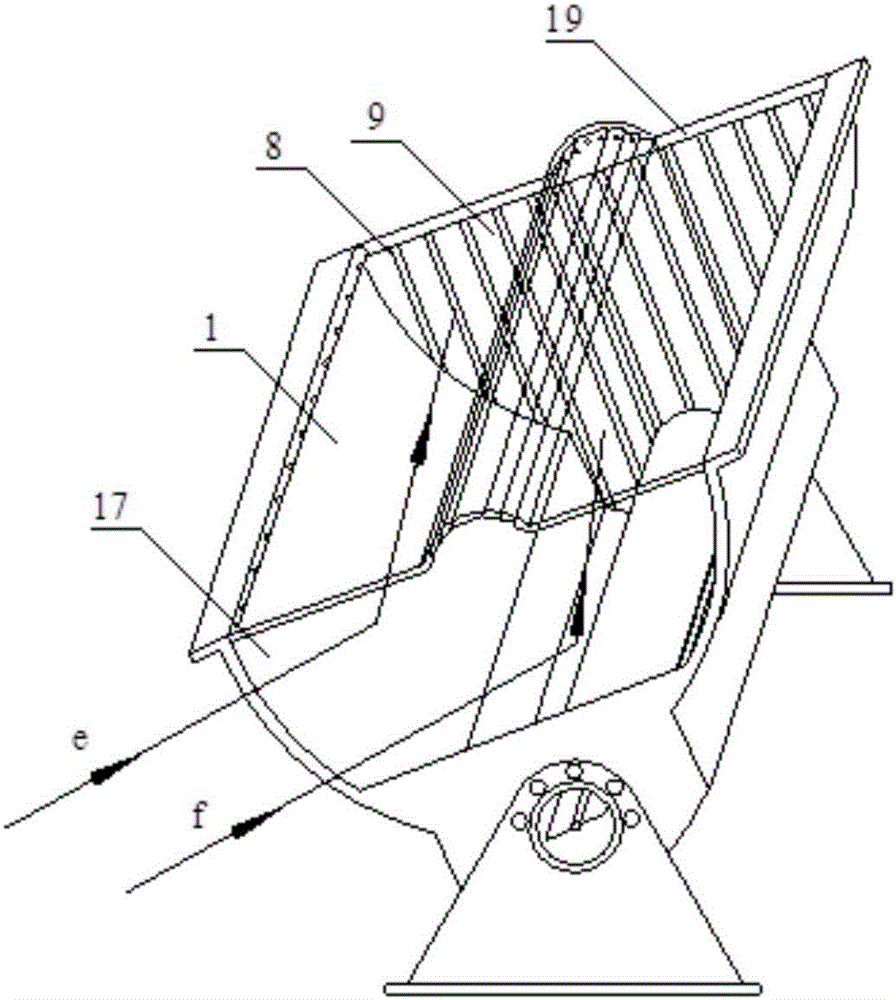

[0021] See attached figure 1 , a composite multi-curved trough solar concentrator with automatic defrosting function, which includes: a concentrator, a glass cover plate 1, a glass vacuum tube receiver 12, a black light-absorbing panel 9 and a tapered hot air duct 5;

[0022] The concentrator is a trough structure, the front and rear sides are semi-parabolic reflective surfaces 2, the bottom surface is a parabolic reflective surface 4, and the two semi-parabolic reflective surfaces 2 and parabolic reflective surfaces 4 are respectively separated by two vertical reflective surfaces 3 Connection; one end of the openings at the left and right ends of the concentrator is closed by the glass light inlet 17 and the side plate 18, and the other end is closed by the black light-absorbing plate 9; air is formed between the black light-absorbing plate 9 and the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com