Inner-support type testing head of cylinder water press testing machine

A hydrostatic test, test head technology, applied in the direction of using stable tension/pressure to test material strength, fluid tightness test, machine/structural component test, etc., can solve the problem of high labor intensity, affecting test accuracy, work The problem of low efficiency is to achieve the effect of reasonable and reliable work, good sealing effect and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

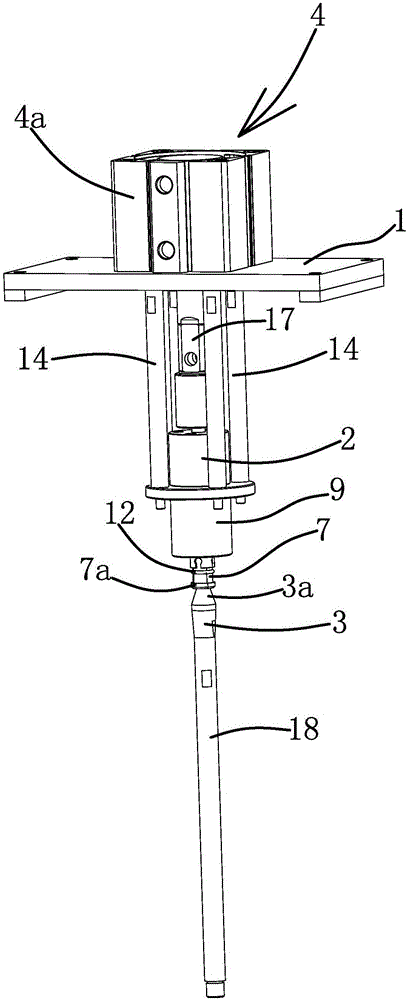

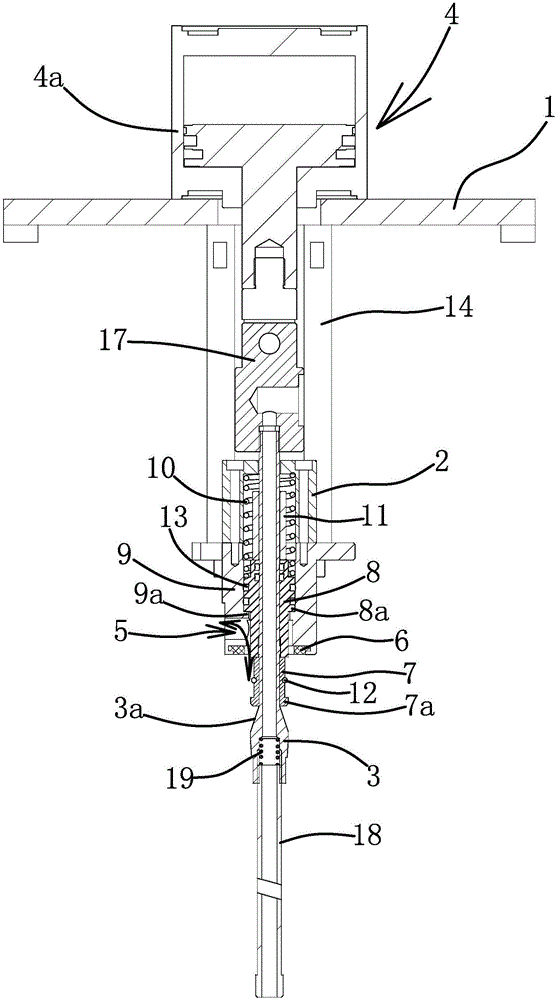

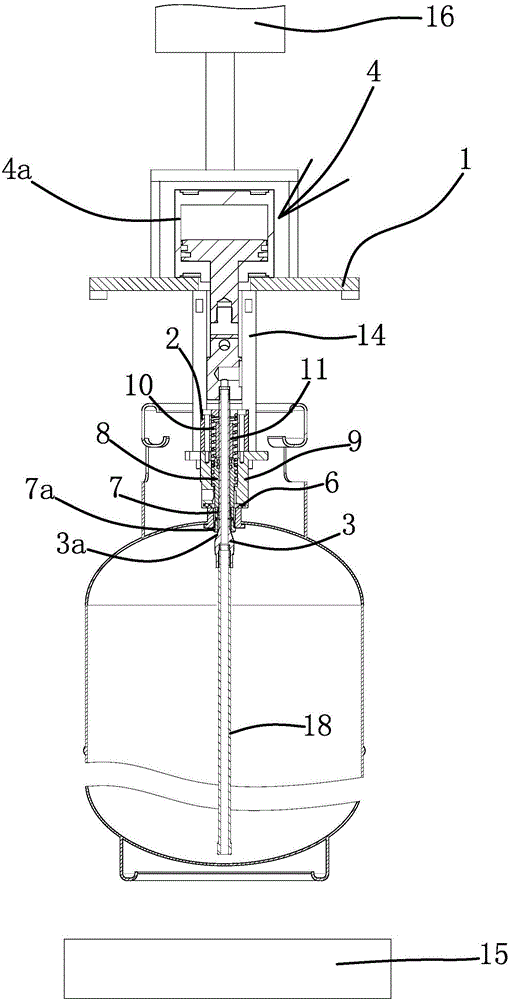

[0026] Such as Figures 1 to 3 As shown, the inner support type test head of the steel cylinder hydraulic testing machine includes a fixed plate 1, the lower side of the fixed plate 1 is fixedly connected with the support cylinder 2 with the opening facing downward, and the inner support shaft seat 9 is connected with the fixed plate 1 through four Column 14 is fixedly connected. The lower end of the support cylinder 2 is coaxially fixed with a cylindrical inner support shaft seat 9, the support cylinder 2 is coaxially provided with a water injection rod 3, and the fixed plate 1 is provided with a driving member 4 capable of driving the water injection rod 3 to reciprocate and axially translate , the driver 4 is a cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com