Structurally integrated cement stabilized gravel base layer or subbase layer design method

A cement stabilization and design method technology, applied in design optimization/simulation, calculation, on-site coagulation pavement and other directions, can solve the requirements that cannot consider the performance of pavement structure materials, the mixture can not effectively control cracking, structure and materials Problems such as design disjoint to achieve the effect of solving shrinkage cracking, good use effect and low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

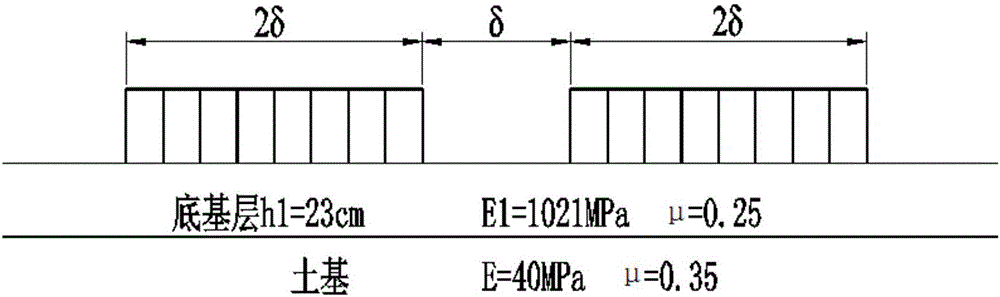

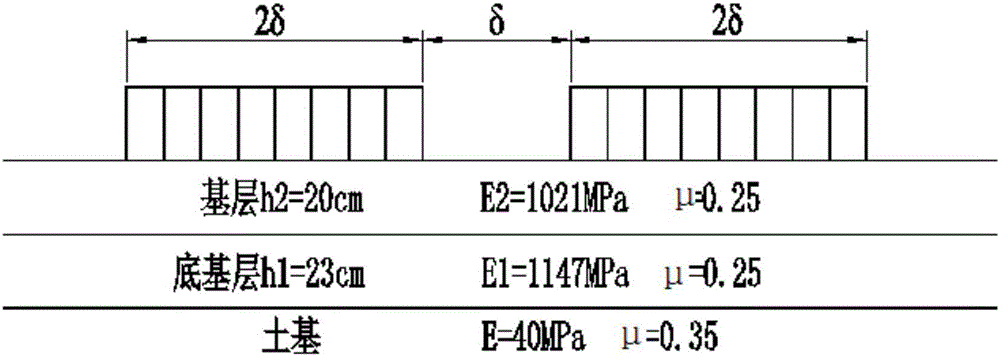

[0058] In this embodiment, an expressway is taken as an example for description.

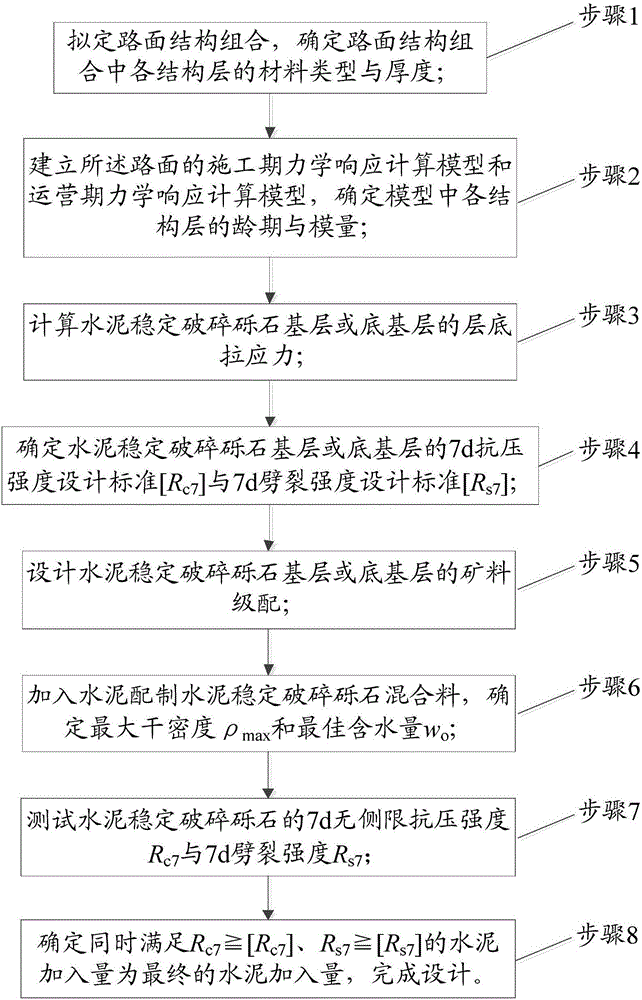

[0059] A method for designing a cement-stabilized broken gravel base or subbase integrated with a structure, comprising the steps of:

[0060] Step 1, formulate the pavement structure combination, determine the material type and thickness of each structural layer in the structure combination; the structure combination at least includes the base layer or the sub-base layer, and the upper layer, with the base layer or the sub-base layer as the design layer, the The base or sub-base material is cement stabilized crushed gravel.

[0061] (1) Traffic volume analysis

[0062] The traffic volume survey results of this expressway in 2016 are shown in Table 1.

[0063] Table 1 Composition of traffic volume in 2016

[0064]

[0065] The standard axle load (BZZ-100) of 100kN for the single-axle double-wheel set used in the design of the new road surface structure converts various axle loads into stan...

Embodiment 2

[0131] In this embodiment, a secondary road is taken as an example for illustration.

[0132] A method for designing a cement-stabilized broken gravel base or subbase integrated with a structure, comprising the steps of:

[0133] Step 1, formulate the pavement structure combination of the secondary road, determine the material type and thickness of each structural layer in the structure combination; the structure combination includes at least the base layer and the upper layer, with the base layer or the sub-base layer as the design layer, the The material of the base or subbase is cement stabilized crushed gravel.

[0134] (1) Traffic volume analysis

[0135] The traffic volume analysis results of this secondary road in 2016 are shown in Table 11.

[0136] Table 11 Traffic volume composition of this secondary road in 2016

[0137]

[0138] The standard axle load (BZZ-100) of 100kN for the single-axle double-wheel set used in the design of the new road surface structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com