Automatic rubberizing device of battery head part

A glue sticking device and battery technology, applied in primary batteries, primary battery manufacturing equipment, battery assembly machines, etc., can solve the problems of difficult quality assurance, great influence on glue positioning accuracy, low efficiency, etc., to achieve stable quality and production high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be described in further detail below in conjunction with the accompanying drawings.

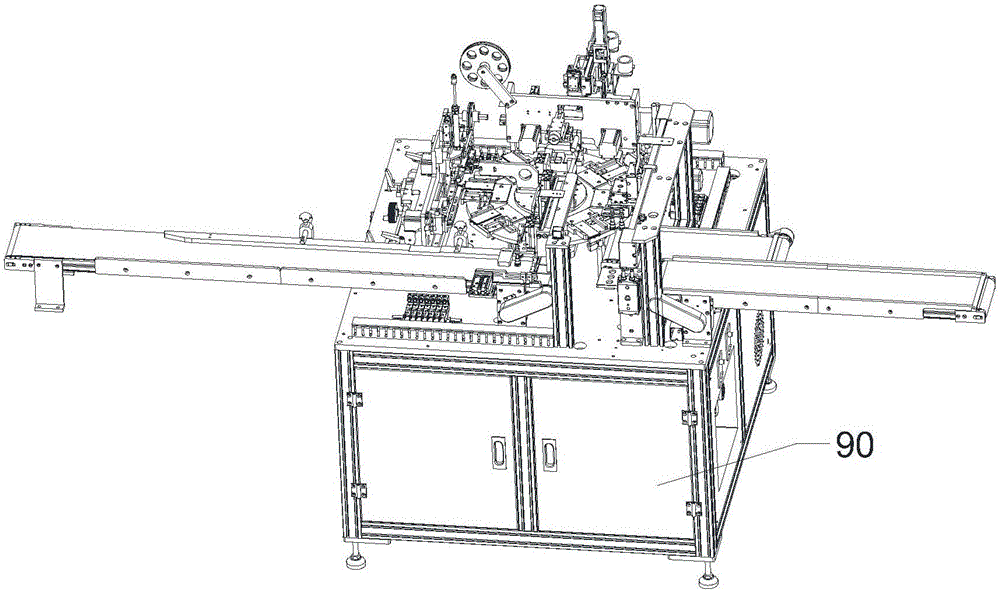

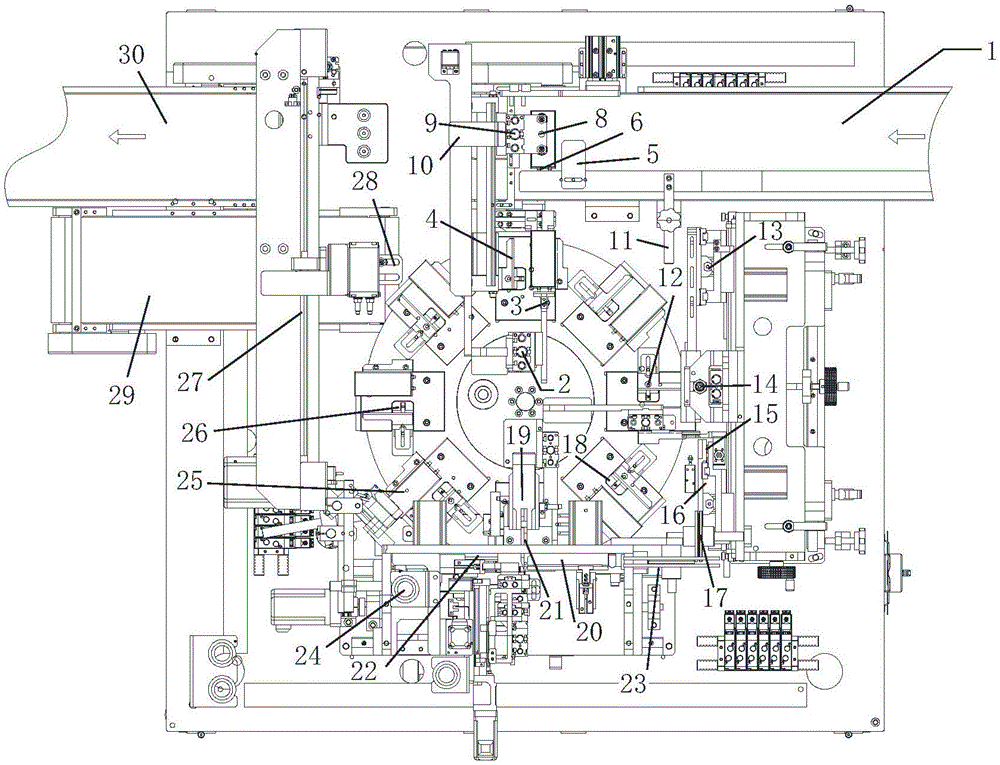

[0068] Such as Figure 1~2As shown, the battery head automatic gluing device of the present invention includes:

[0069] Rack 90,

[0070] The spatial positional relationship of the front, rear, left, and right is as follows: figure 2 Shown as a benchmark, the purpose is to clearly describe the product structure, not to limit the product structure only so,

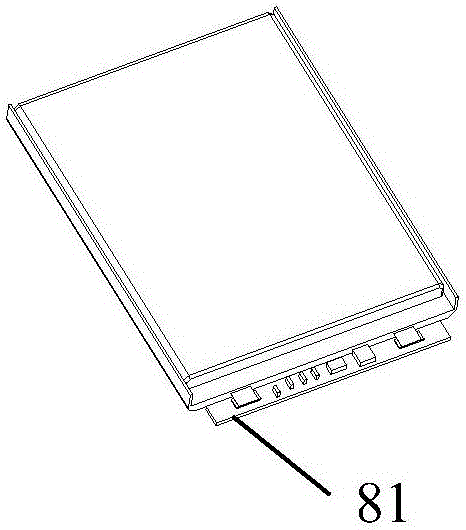

[0071] On the right rear side of the top surface of the frame, a feed belt line 1 is provided, and the feed belt line 1 is used to transmit the battery 6 to the automatic glue sticking device for the battery head, such as image 3 As shown, the battery 6 is a battery to be processed, which includes at least one battery end cover 81,

[0072] A sensor 7 is arranged on the left side of the feed belt line 1, and the specific model of the sensor 7 can be a reflective sensor CX-442,

[0073] On the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com