Stack simulator-based matching test method for fuel battery air supply subsystem

An air supply and fuel cell technology, applied in the direction of fuel cells, fuel cell groups, electrical components, etc., can solve the problems of no air supply subsystem matching test, inability to air supply subsystem matching test evaluation, complex methods, etc., to reduce The effect of testing complexity, improving development efficiency, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

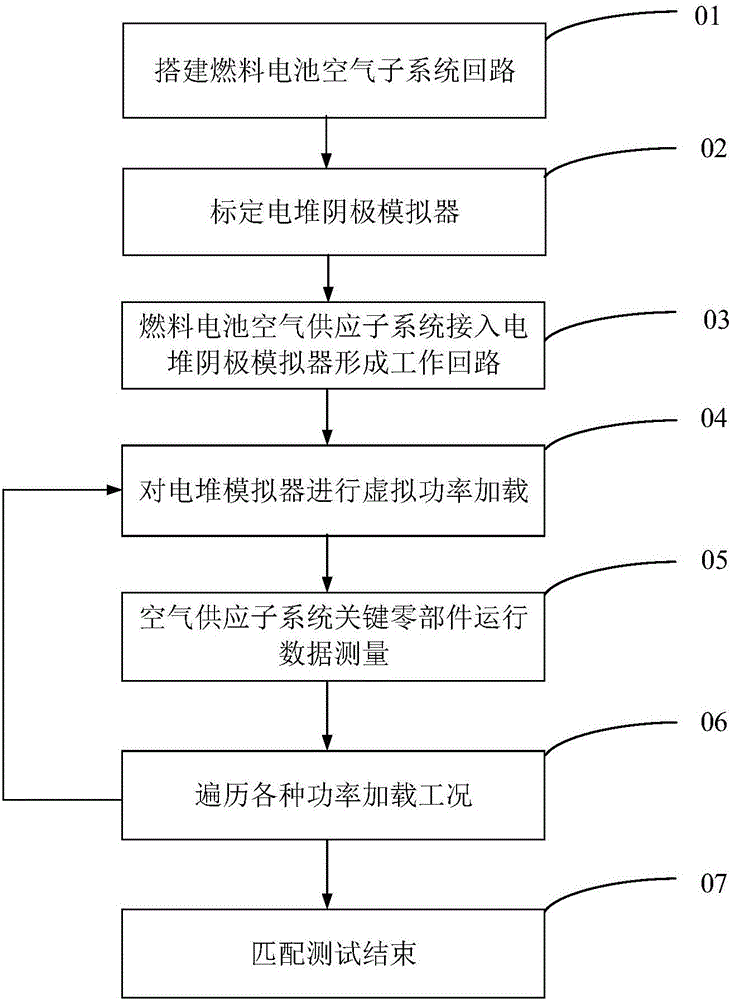

[0034] like figure 1 Shown, a fuel cell air supply subsystem matching test method based on stack simulator, the method includes the following steps:

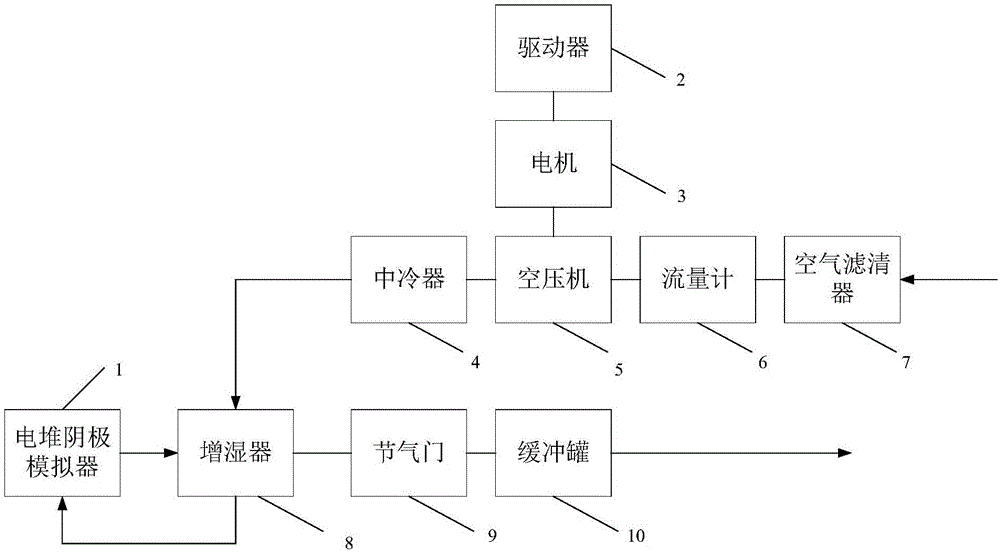

[0035] Step 01: Build the air supply subsystem of the fuel cell, and connect the key components of the air subsystem such as the air compressor, humidifier, and back pressure valve to the pre-set air subsystem circuits. These circuits can be: ①General Air supply and humidification circuit; ② circuit with air heating; ③ circuit with local humidification circuit; ④ circuit with idle exhaust decompression; ⑤ circuit with exhaust gas recirculation. In this embodiment, ① a conventional air supply and humidification circuit is adopted.

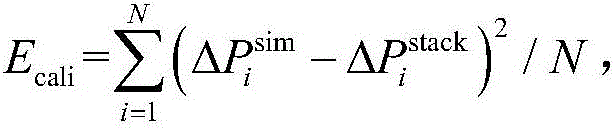

[0036] Step 02: Build the stack cathode simulator and perform calibration to simulate the fuel cell stack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com