Two-stage magnetostrictive galvanometer deflection drive mechanism

A technology of magnetostriction and driving mechanism, which is applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. problem, to achieve the effect of ultra-precision control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

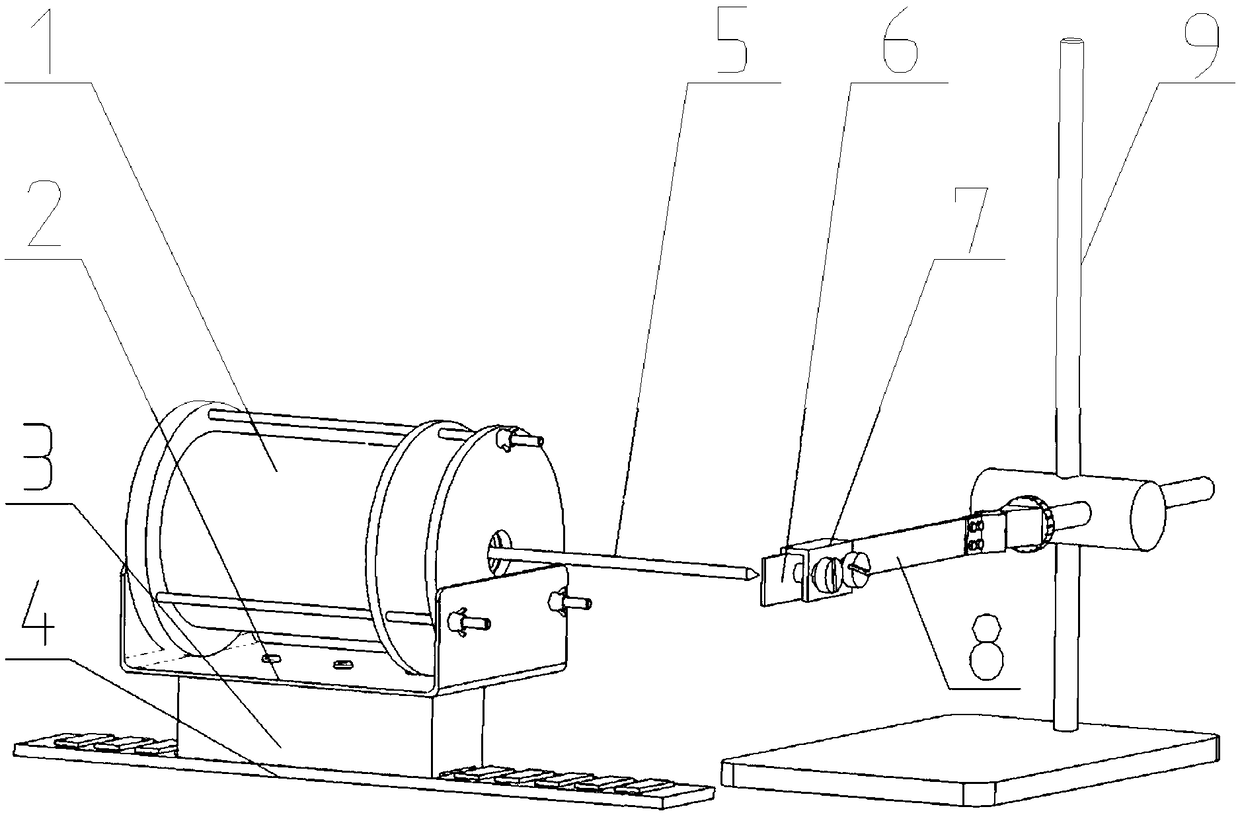

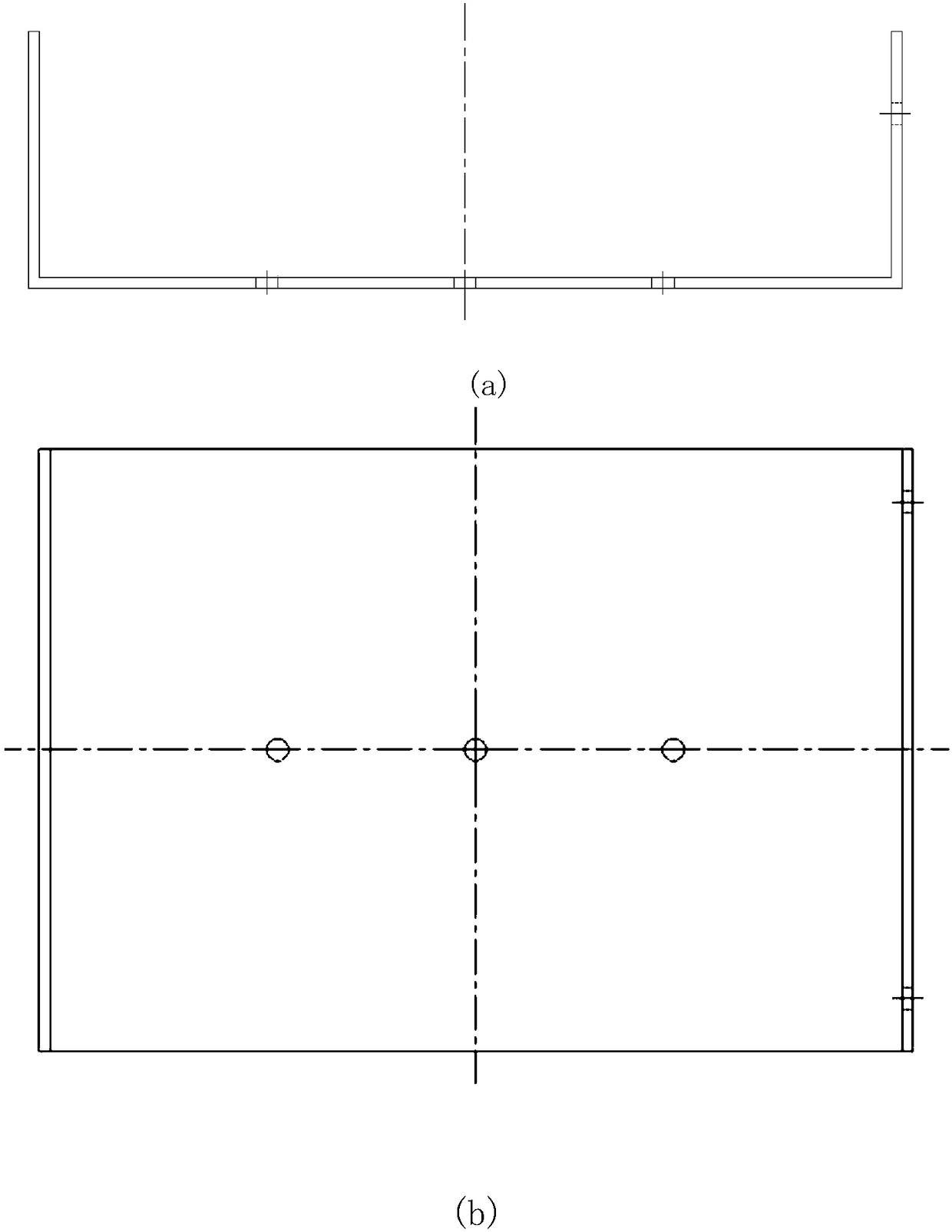

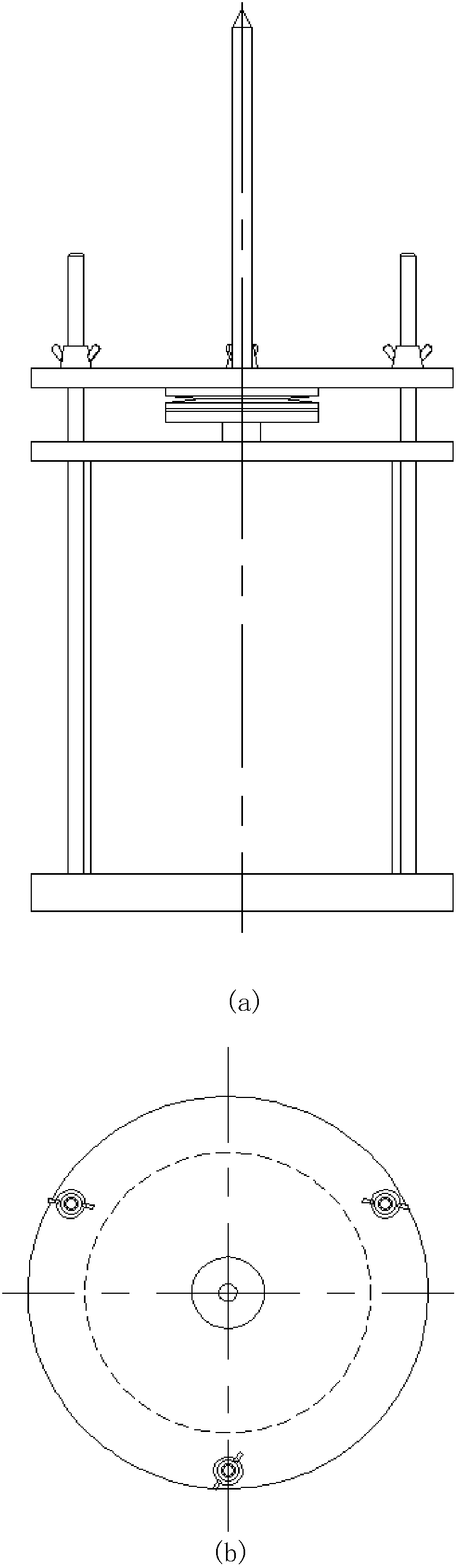

[0028] Below in conjunction with accompanying drawing, the present invention will be further described:

[0029] The invention is a two-stage magnetostrictive oscillating mirror deflection driving mechanism, which combines the motor drive and the giant magnetostrictive material drive by utilizing the excellent performance of giant magnetostrictive materials, and proposes a two-stage magnetostrictive oscillating mirror deflection drive mechanism. Working principle of the present invention: the device is mainly composed of a linear motor and a giant magnetostrictive actuator. When the linear motor is working, it can effectively control the position of the galvanometer in the galvanometer laser scanning system quickly and in a wide range. adjustment; on this basis, let the giant magnetostrictive actuator work, use the magnetostrictive effect characteristics of the giant magnetostrictive material, control the elongation of the material by adjusting the driving magnetic field, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com