A prefabricated component for fixing polymer waterproof material and its application method

A polymer waterproof and pre-installed technology, which is applied in building components, building insulation materials, building structures, etc., can solve problems such as cracking, and achieve the effects of improving construction efficiency, convenient and fast construction, and reliable waterproof quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

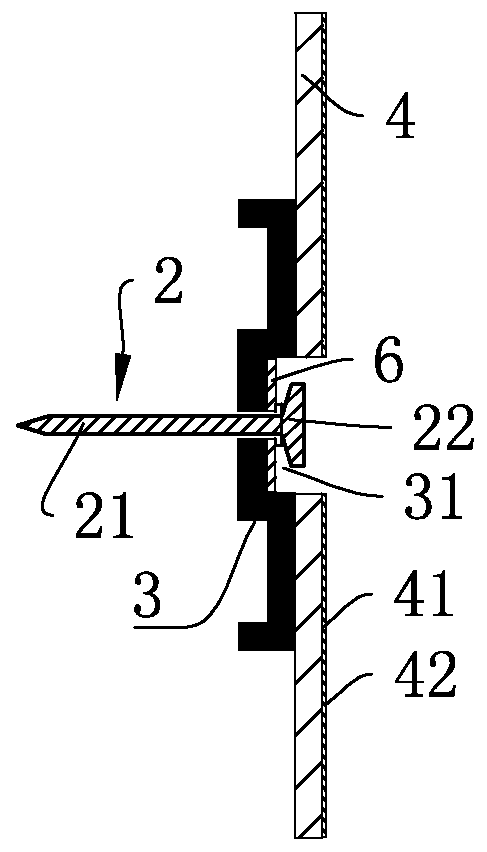

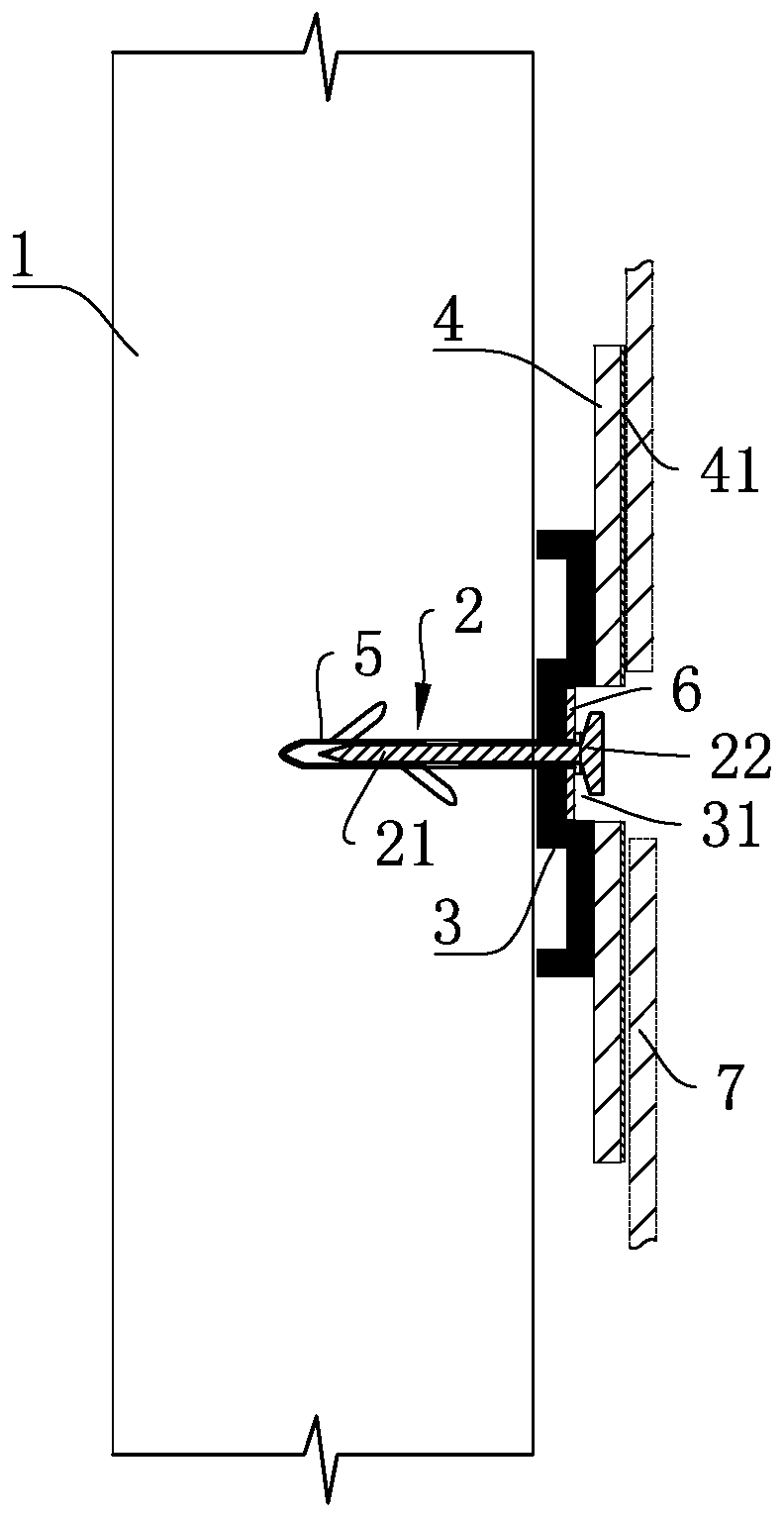

[0022] like figure 1 As shown, a prefabricated component for fixing polymer waterproof materials includes three parts: expansion screw 2, plastic washer 3 and polymer coil rubber pad 4. The middle part of plastic washer 4 is provided with a groove 31, and the inside of the groove is Metal spacer 6 is arranged, and macromolecule coiled material rubber pad 4 comprises three parts: polymer self-adhesive glue 41 and isolation film 42 adhered by polymer waterproof sheet and its surface. The expansion screw 2 runs through the middle of the plastic washer 3, and the polymer coil rubber pad 4 is fixedly attached to the side of the plastic washer 3 away from the nail body 21, and the fixing method can be welding or bonding; the side away from the nail body 21 is provided with The polymer self-adhesive 41 , the surface area of the polymer coil pad 4 is greater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com