Synchronous wheel of integrated structure

An integral structure, synchronous wheel technology, applied in the direction of elements with teeth, belts/chains/gears, portable lifting devices, etc., can solve the problems of belt retaining ring falling off, equipment operation accident risk, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

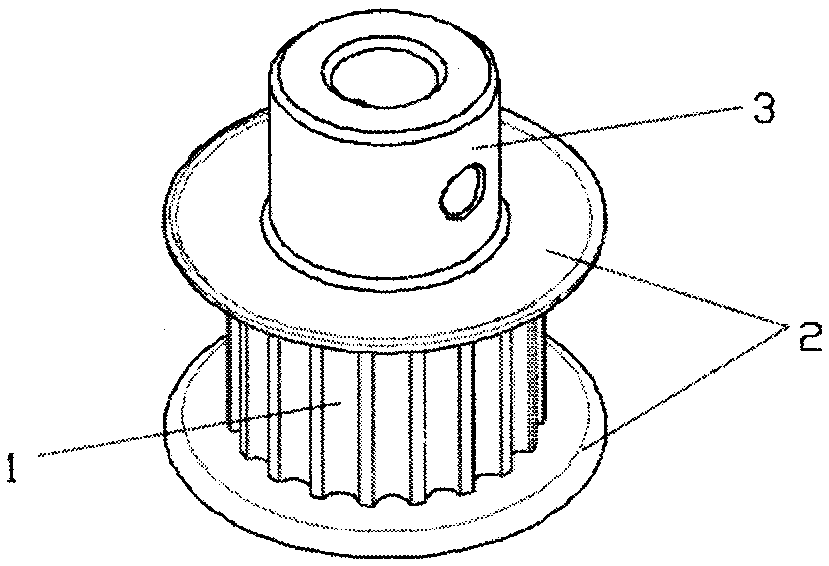

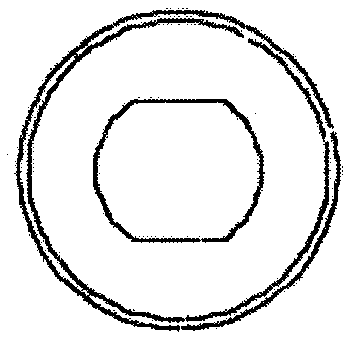

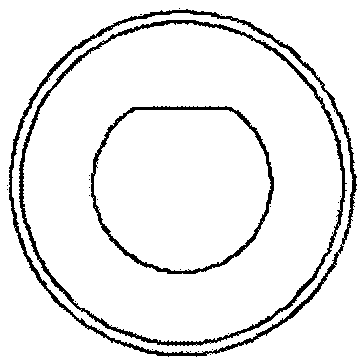

[0010] like figure 1 As shown, the synchronous wheel of a kind of overall structure of the present invention comprises synchronous gear (1), belt retaining ring (2), axle (3), and raw material is put into the mold of designing, and the material is pressed in the way of pressure etc. The mold is pressurized to achieve the complete filling of the material in the mold, and the fully filled blank is taken out from the mold, and it is further refined or sintered, machined, decaped, and surface treated to meet the synchronous wheel industry standard. The product.

[0011] As another embodiment, the designed three-dimensional modeling data of the synchronous wheel is input into the digital controller, and the additive technology is used to carry out three-dimensional additive materials according to the three-dimensional modeling data of the product, until the 1:1 product molding is completed.

[0012] The above is only a preferred embodiment of the present invention, and does not li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com