Vertical air duct cooling chassis

A vertical air duct and chassis technology, which is applied in the field of vertical air duct heat dissipation chassis, can solve the problems of low heat dissipation efficiency of the chassis, and achieve the effects of easy cleaning, increased heat dissipation speed, and improved heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

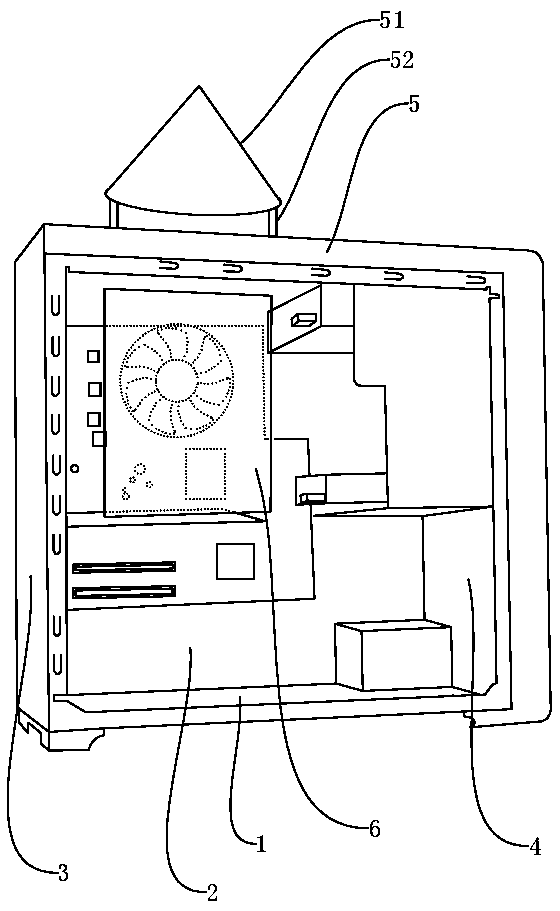

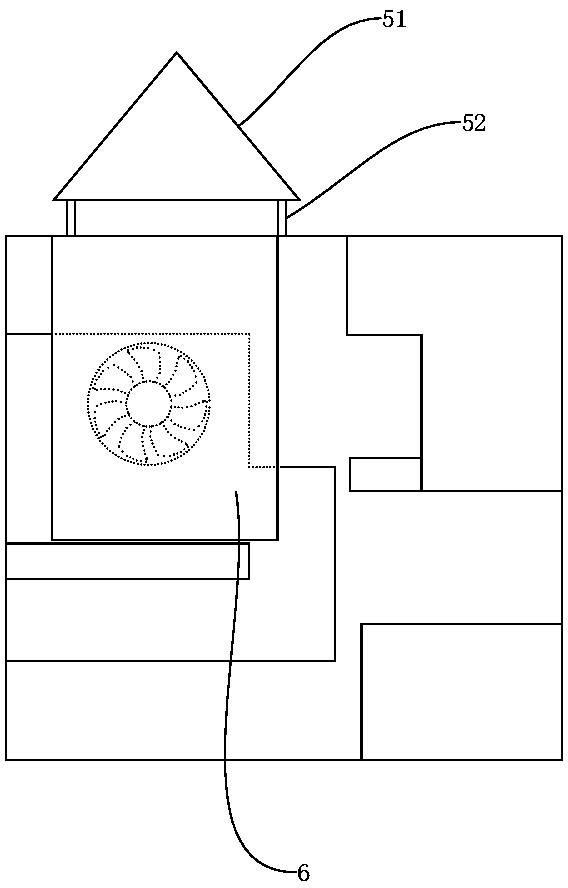

[0031] Basic as attached figure 1 , figure 2 Shown: the vertical air duct type heat dissipation cabinet of this embodiment, including:

[0032] Bottom plate, the bottom plate is uniformly provided with ventilation holes, the bottom plate is bonded with a sponge dust-proof pad, and there are fixed connectors around the sponge dust-proof pad. The connectors are made of rectangular plastic products with the same shape as the bottom plate. Threaded connection with the bottom plate;

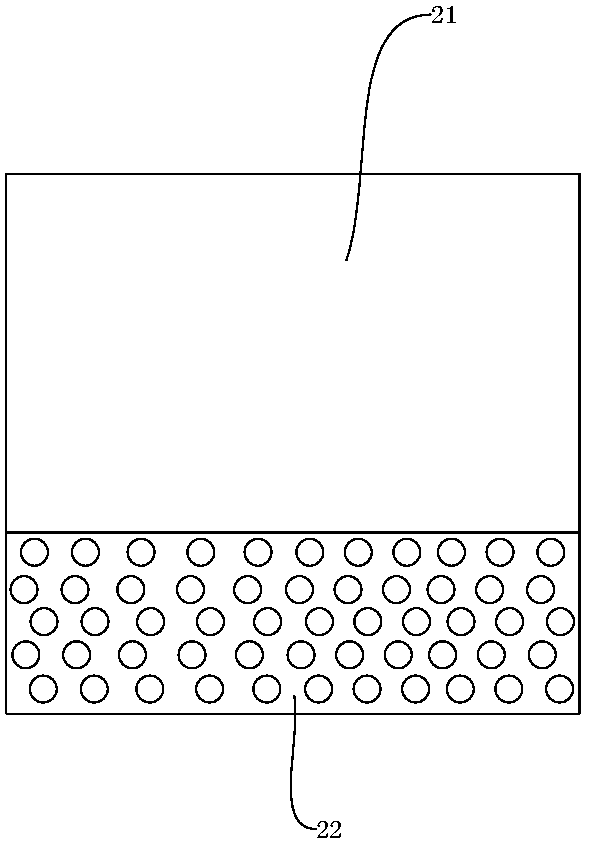

[0033] Two side plates, the side plates are all hollow structures, both include an outer plate 21 and an inner plate 22, the inner plates 22 are respectively fixed on both sides of the bottom plate by welding, and are perpendicular to the plane where the bottom plate is located, and the bottom of the inner plate 22 is provided with The air inlet, the air inlet is provided with an exhaust fan, and the air inlet is provided with a dust-proof thin net made of teda. Set the separator 23 (such as ima...

Embodiment 2

[0040] Compared with Embodiment 1, the difference is that a water storage tank 7 is provided under the inner panel 22, and the water storage tank 7 is located below the air inlet (such as Figure 4 As shown), the deflector 6 is provided with fins in the vertical direction, and the deflector 6 is provided with grooves for fixing the fins, and the fins are embedded in the grooves. The fins can better guide the graphics card and the CPU out of the air outlet, and the fins are detachably connected to the deflector 6, which is convenient for cleaning.

Embodiment 3

[0042] Compared with Embodiment 2, the difference lies in that an air guide tube is provided between the connecting rod 52 and the cover plate 5 , and the air guide tube is screwed to the cover plate 5 . The air duct can further enhance the effect of the chimney effect, speed up the flow rate of air in the chassis, and further improve the heat dissipation effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com