Cutter row used for reverse turning of end face on vertical lathe

A technology of turning end faces and cutter rows, applied in the direction of tool holders, etc., can solve problems such as processing quality and safety hazards, poor flatness of the processing surface, and product quality impact, and achieve long processing time, low probability of fracture, and guaranteed processing. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

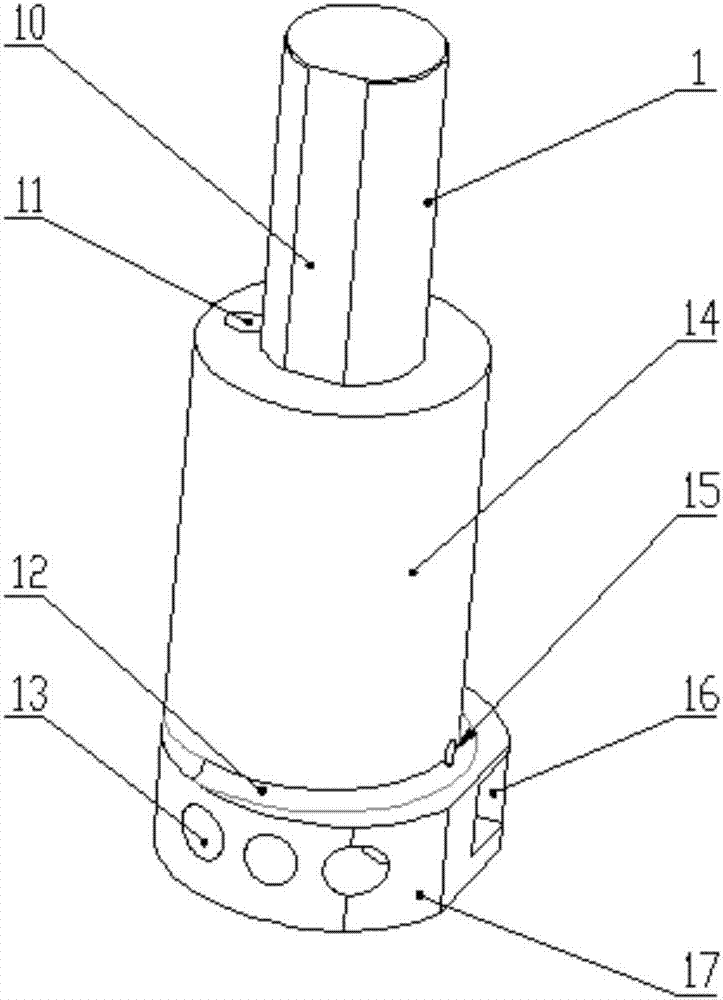

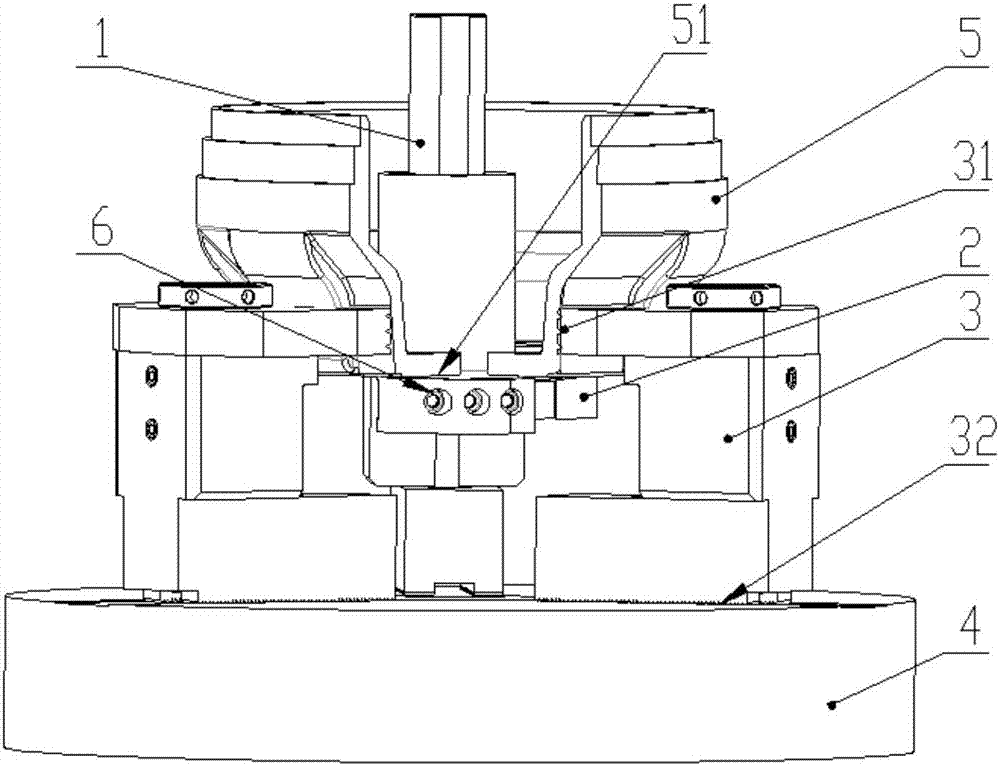

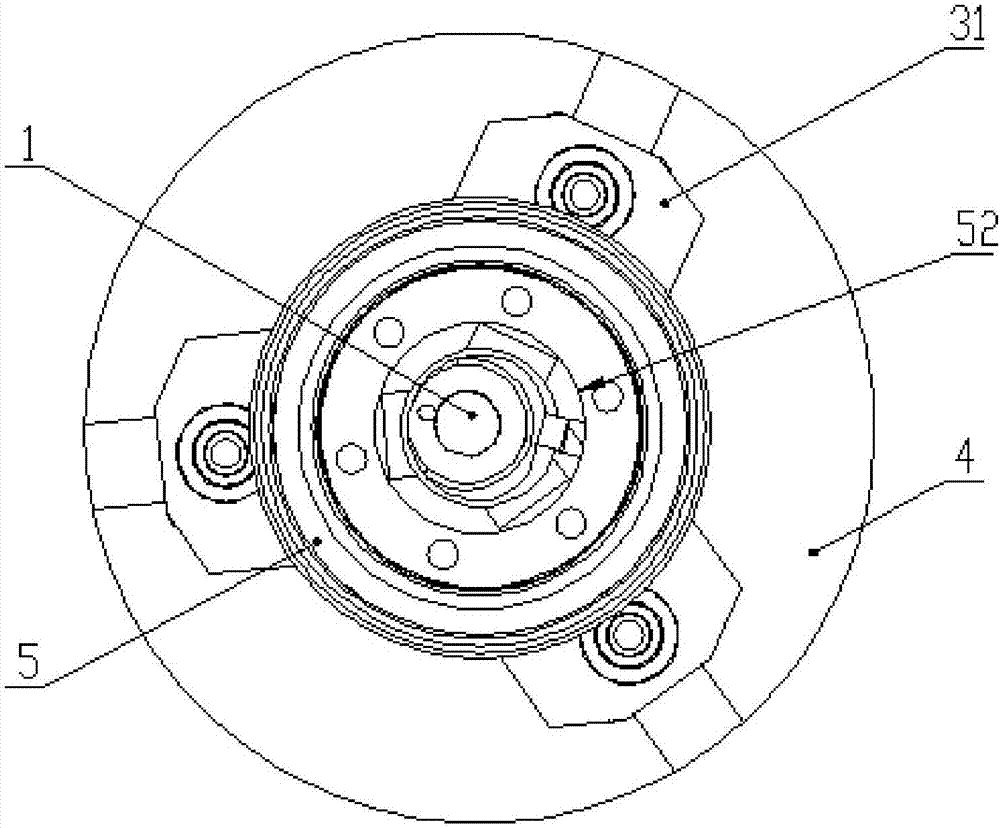

[0021] like figure 1 The cutter row used for the upper and reverse turning end of the vertical lathe includes a cylindrical cutter rod 1 with a mounting and positioning plane on the side; it is fixed at the lower end of the cutter rod 1 and the cutter rod forms a cylinder with a stepped shaft shape concentric with the central axis Shape knife row middle part 14; Be fixed at the bottom 17 of cylindrical knife row bottom 17 of non-concentric axis step axis shape that is fixed on the bottom of knife row middle part 14 and cylindrical knife row middle part 14; Be located at the cutter on the bottom 17 sides of cylindrical knife row; The connection between the bottom 17 of the cylindrical knife row and the middle part 14 of the cylindrical knife row is provided with an excessively rounded corner 12, through the setting of the excessively rounded corner 12, the damage to the knife row caused by the stress concentration of the product when the knife row is used is reduced, and it can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com