Electric safety clamp technology capable of rapidly conducting releasing and clamping

A safety clamping and fast technology, applied in the direction of clamping, manufacturing tools, workpiece clamping devices, etc., can solve problems such as low efficiency, excessive clamping force, and clamping marks on the workpiece, and achieve the effect of flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with schematic diagram, specific embodiment and assembly drawing, make further explanation:

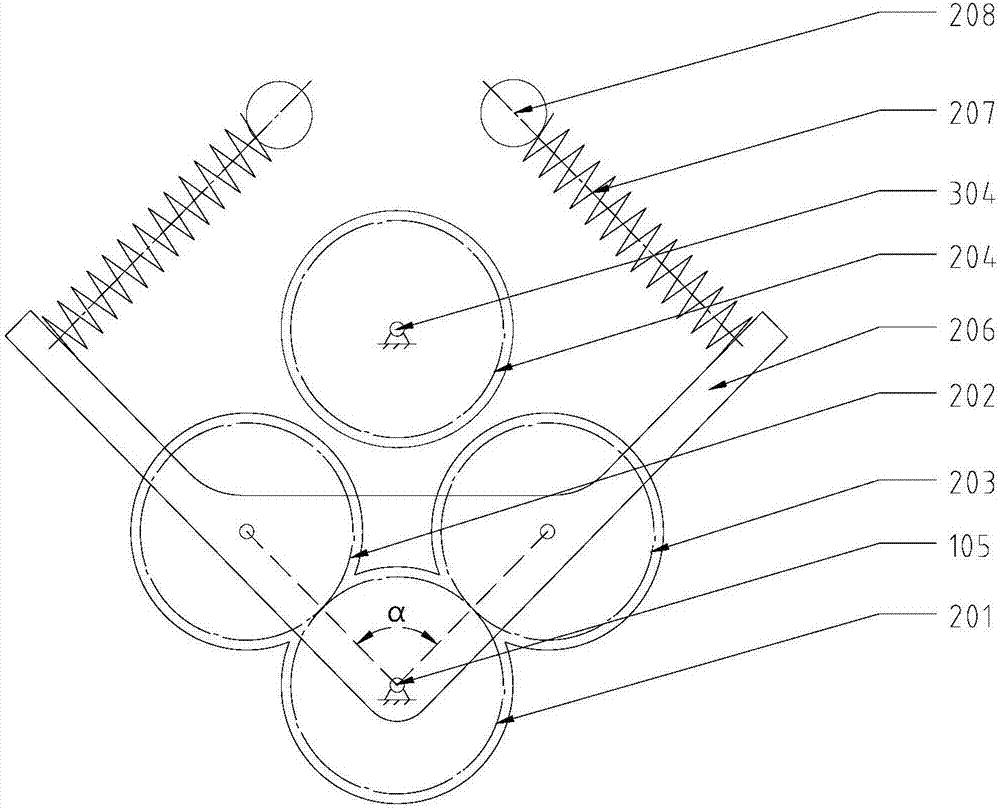

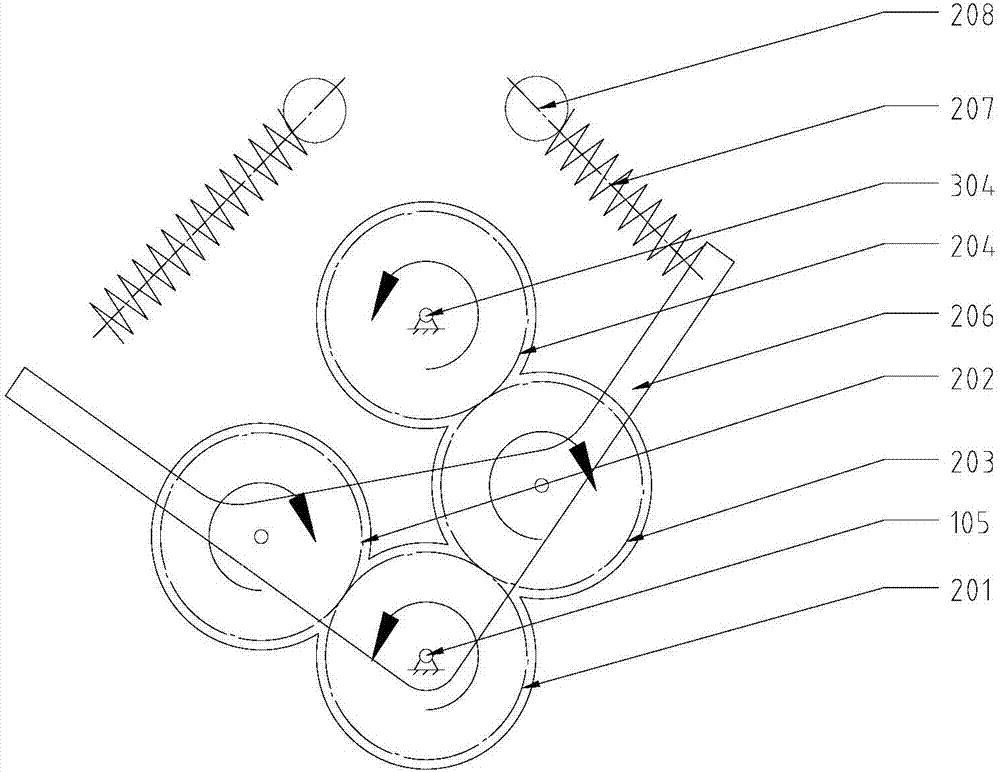

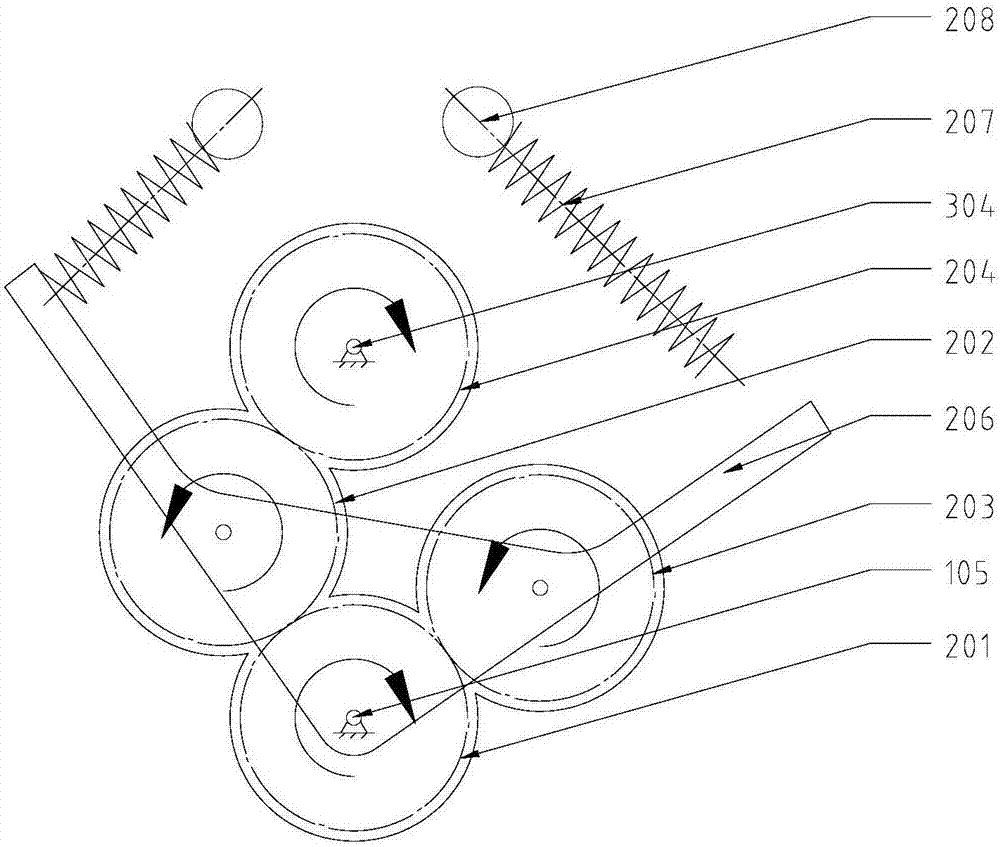

[0027] see Figure 4 , 5 , 6, 7, there is respectively a contact switch 401,402 at the travel limit position of the movable pliers 305 on the fixed pliers 310, and a pressure sensor switch 403 is arranged at the jaws of the fixed pliers 310; the fixed pliers 310 and the screw slider 307 is slidingly connected, and connected by screw 304 for transmission. The movable caliper body 305 is axially installed on the screw slider 307 and fixed with the fixing screw 306; one end of the screw 304 is a square shaft section 312, which is positioned by a backing ring 311 and matched with a corresponding The detachable handle can realize manual clamping, and the other side of the screw rod 304 is fixed with the driving gear 204, and the positioning of the axle sleeve 303, the fixing of the nut 301 and the cotter pin 302 are arranged; Drive gear 201, intermediate gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com