Concrete sample curing room and temperature adjusting method thereof

A technology for concrete specimens and curing rooms, applied in temperature control, control/regulation systems, non-electric variable control, etc., can solve the problems of temperature difference, low control accuracy, and inaccurate performance index detection, and achieves improved efficiency, temperature Adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

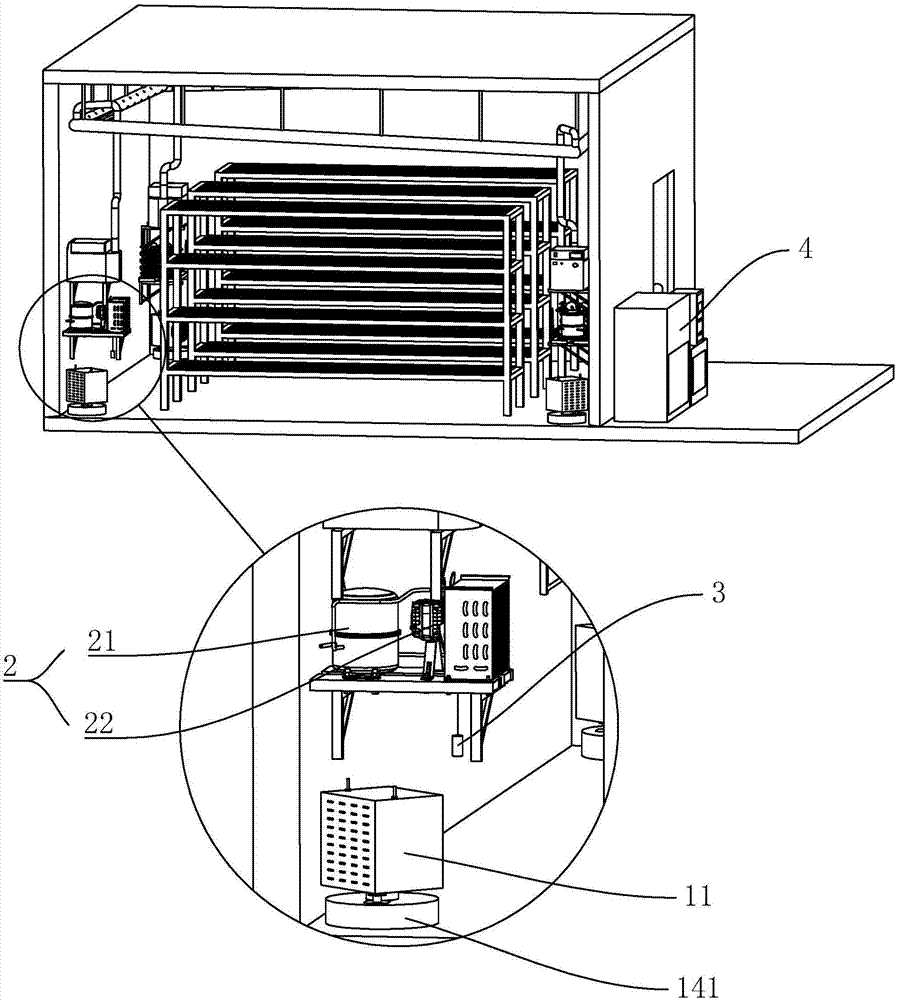

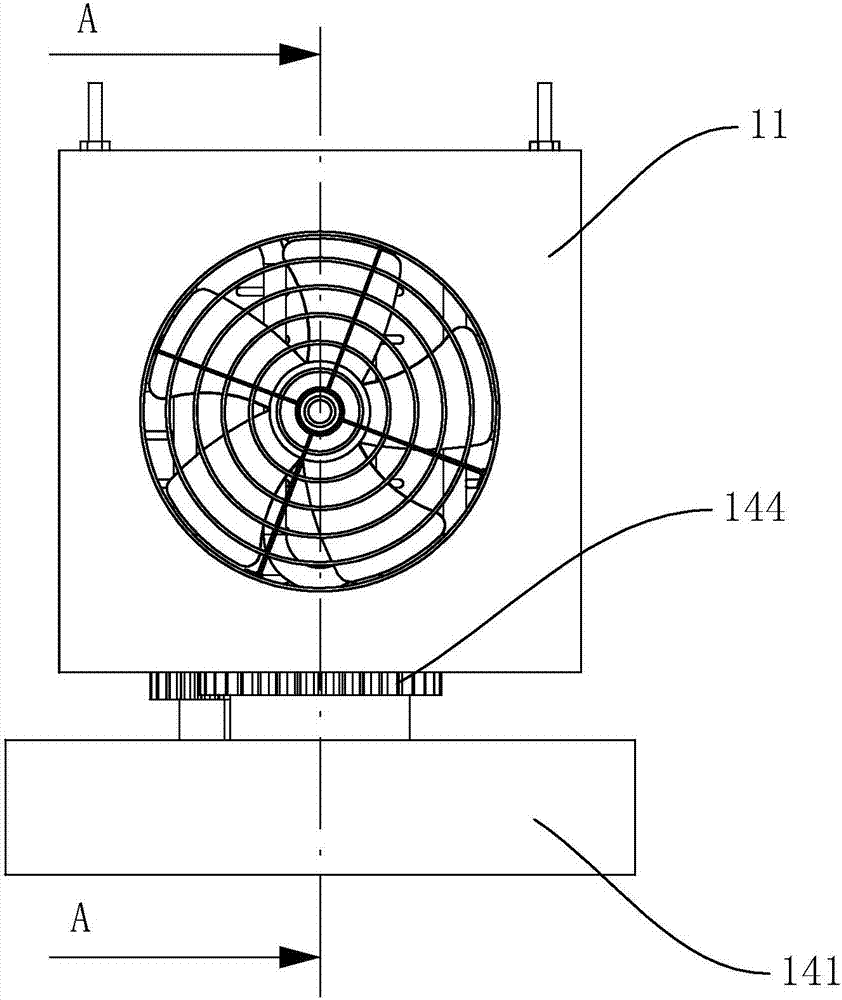

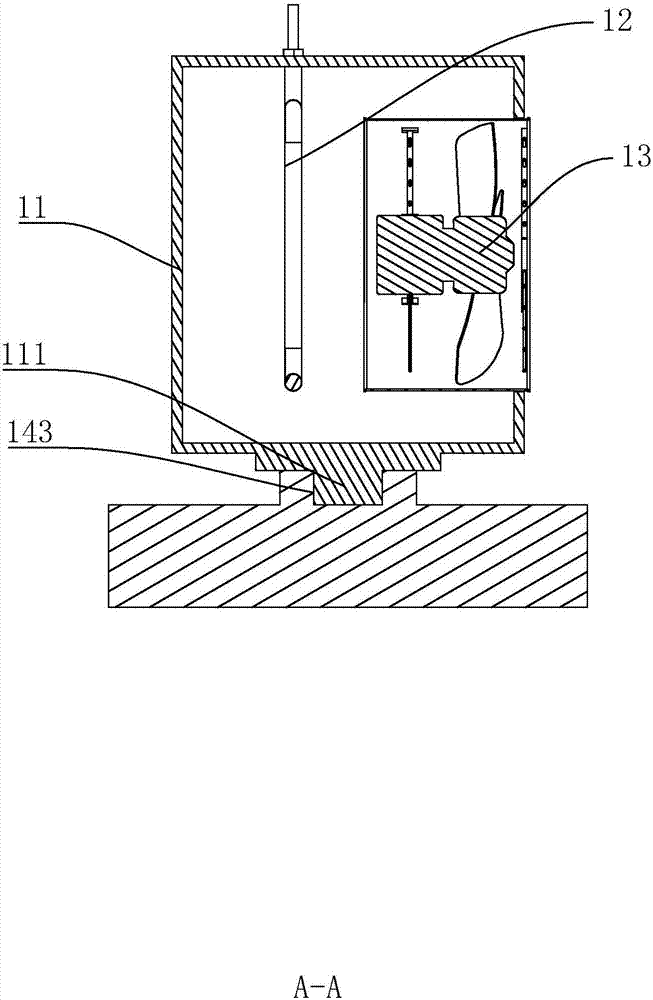

[0050] Embodiment 1, a disclosed concrete specimen curing room, such as figure 1 As shown, it includes a number of temperature detection elements 3 for detecting the indoor temperature of the curing room, a heating device 1 for raising the indoor temperature of the curing room, a cooling device 2 for lowering the indoor temperature of the curing room, and a heating device 1 for controlling The control terminal 4 that is opened and closed with the cooling device 2, the heating device 1 and the cooling device 2 are provided with a number of temperature detection elements 3, the heating device 1 and the cooling device 2 are in one-to-one correspondence with each other, and the temperature detection elements 3, The heating device 1 and the cooling device 2 are a group of temperature adjustment components, preferably four groups of temperature adjustment components, and are respectively arranged at the four corners of the curing room; the temperature in the curing room is monitored ...

Embodiment 2

[0065] Embodiment 2, a temperature adjustment method based on the concrete specimen curing room, preferably using four sets of temperature adjustment components, the temperature detection element 3 outputs a temperature detection signal to the control terminal 4 according to the indoor temperature of the curing room, and the control terminal 4 is preset with The temperature reference value signal and compare the temperature detection signal with the temperature reference value signal, wherein the temperature reference value signal is a range preferably 20 ± 2 ° C, in the case of higher than the temperature reference value signal is to select 22% of the situation, in Below the situation of the humidity reference value signal is to choose the situation of 18%.

[0066] Such as Figure 5 As shown, if there are one or more temperature detection signals lower than the temperature reference value signal, the control terminal 4 controls the heating device 1 at the corresponding posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com