Injection mold

An injection mold and fixed mold technology, applied in the field of injection molds, can solve the problems of bristle deformation, weak cleaning effect, and short effective cleaning effect time, and achieve the effect of improving the effective service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below with reference to the accompanying drawings.

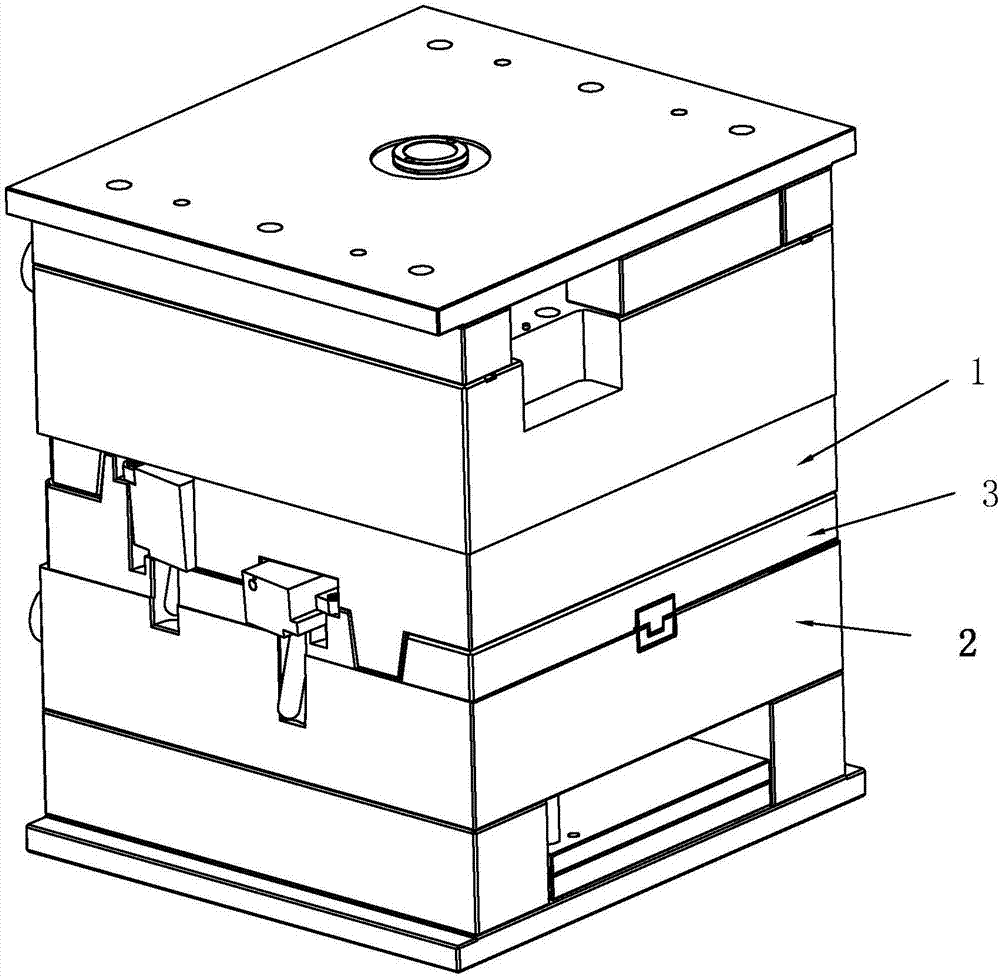

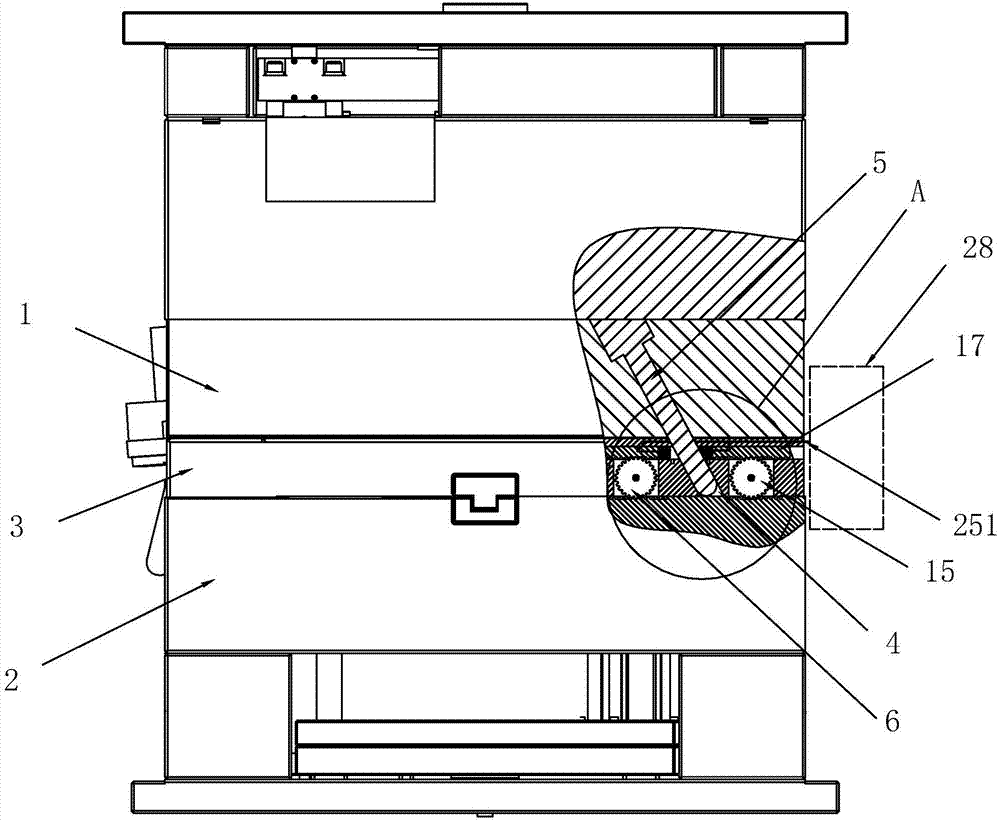

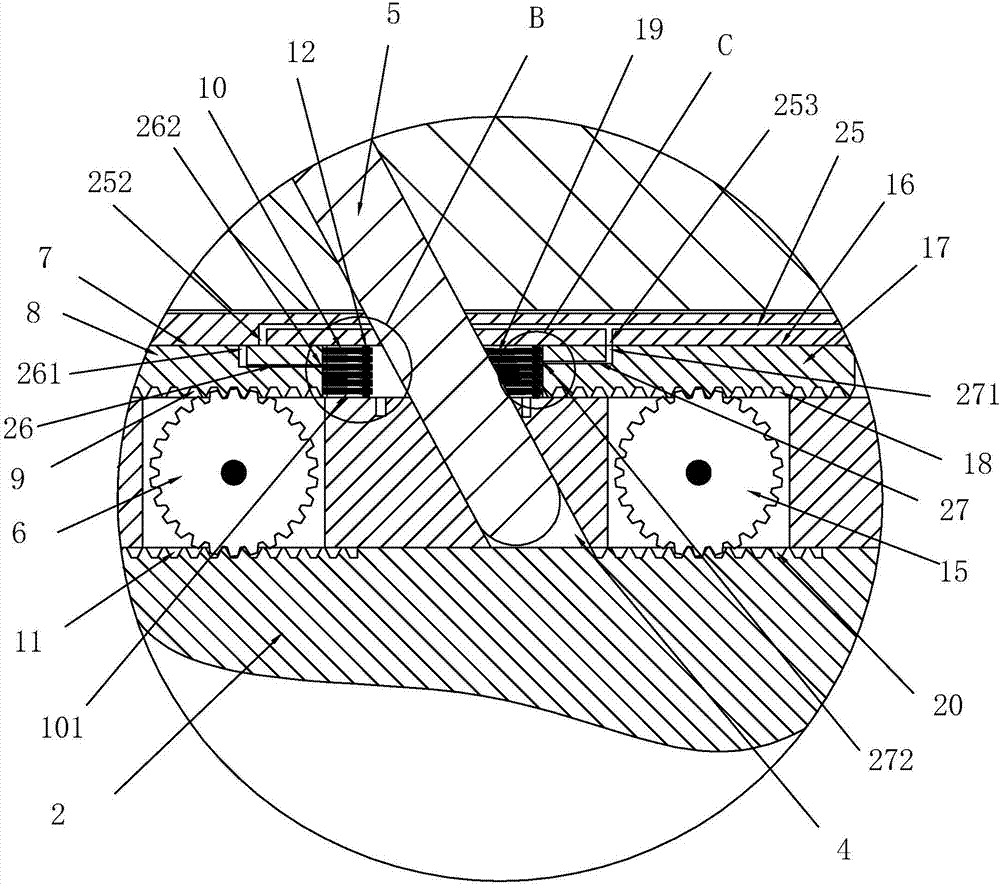

[0044] An injection mold, see figure 1 as well as figure 2 As shown in the figure, it includes a fixed mold 1 and a movable mold 2. The fixed mold 1 and the movable mold 2 can be close to or away from each other. A slider 3 is arranged between the movable mold 2 and the fixed mold 1, and the slider 3 slides. It is arranged on the side wall of the movable mold 2 close to the fixed mold 1. The mold opening and closing direction between the movable mold 2 and the fixed mold 1 is perpendicular to the sliding direction of the slider 3. The die 1 is connected with a toggle slant pin 5 that cooperates with the slanted hole 4. When the movable die 2 and the fixed die 1 are separated or approached, the toggle slant pin 5 will drive the slider 3 to slide left and right.

[0045] There are two main mechanisms in the slider 3:

[0046] The first part of the organizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com