A Dry Separation Recovery System for Iron-Containing Useful Rock

A recovery system and dry separation technology, applied in solid separation, chemical instruments and methods, solid waste removal, etc., can solve the problems of non-comprehensive recovery, high recovery cost, waste of iron ore resources, etc., to prevent electricity bills and equipment depreciation Loss, short connection time, avoiding wasteful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

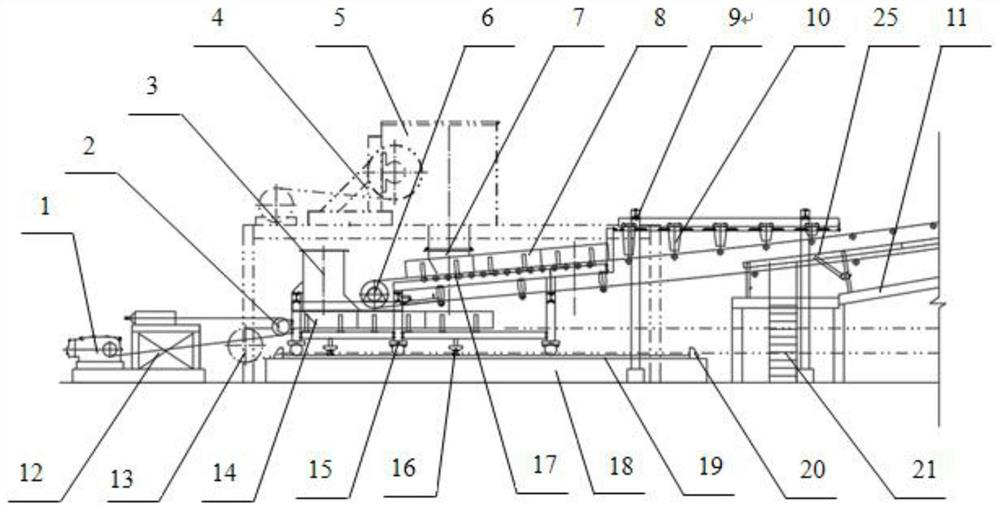

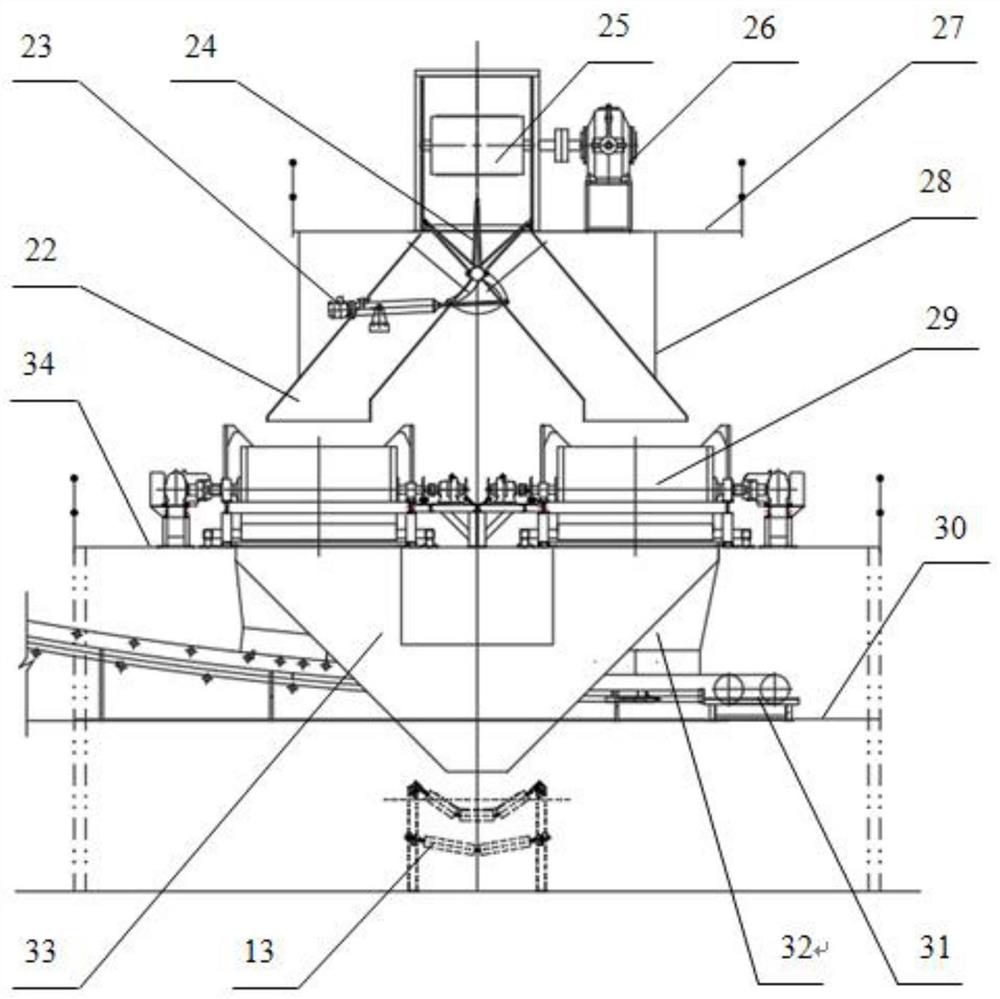

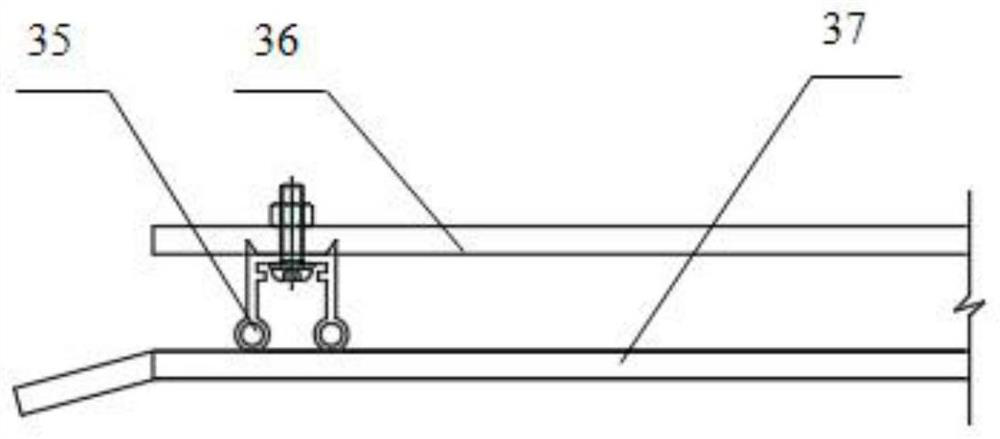

[0026] In order to better describe the present invention, a dry separation and recovery system for iron-containing useful rock of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0027] Depend on figure 1 A schematic diagram of the structure of the receiving part of a dry separation and recovery system for iron-containing useful rocks of the present invention is shown in conjunction with figure 2 It can be seen that a kind of iron-containing useful rock dry separation recovery system of the present invention is composed of the iron-containing useful rock dry separation recovery system material receiving part and the iron-containing useful rock dry separation recovery dry separation part:

[0028]The receiving part of the iron-containing useful rock dry separation recovery system contains the original stope main tape 4 and the original dump site main tape 13; the fixed slide pipe 5 is installed on the head of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com