Mobile 3D printer and printing method thereof

A 3D printer, mobile technology, applied in the field of 3D printing, can solve the problems affecting printing speed, long curing time, long detachment time, etc., to achieve the effect of shortened printing time, short curing time and fast printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

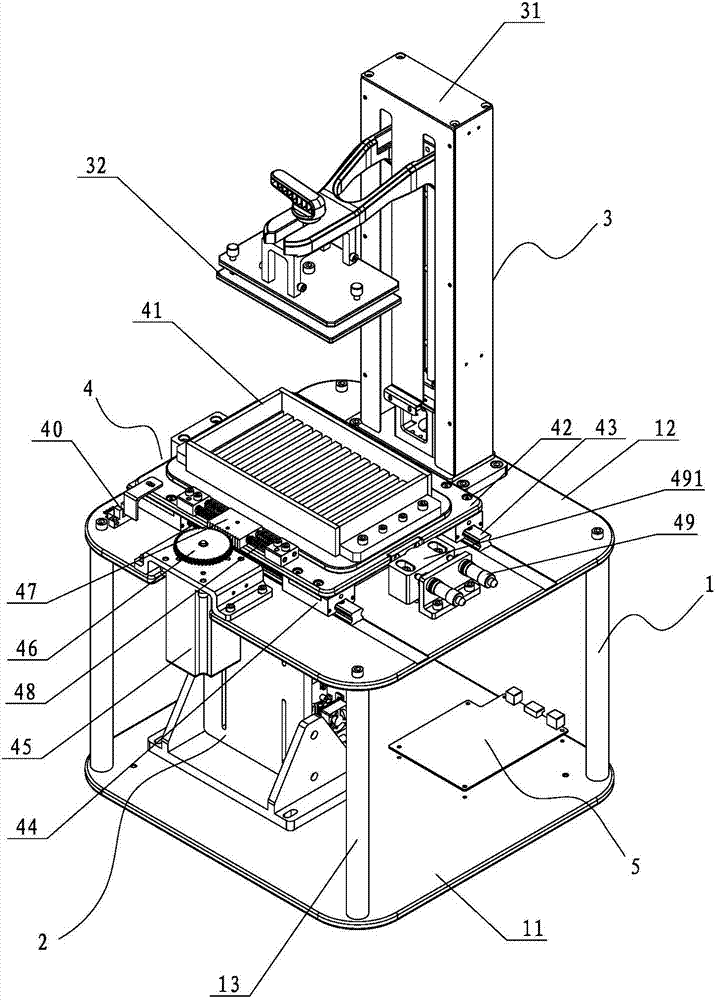

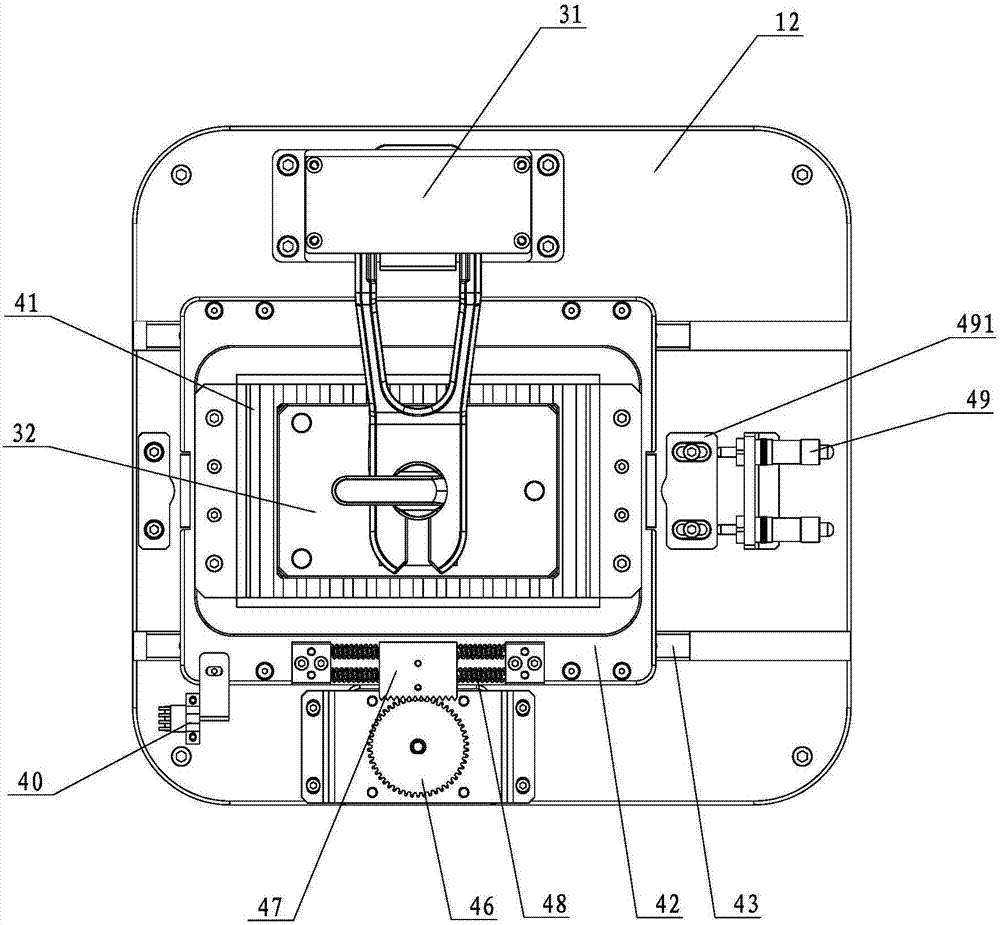

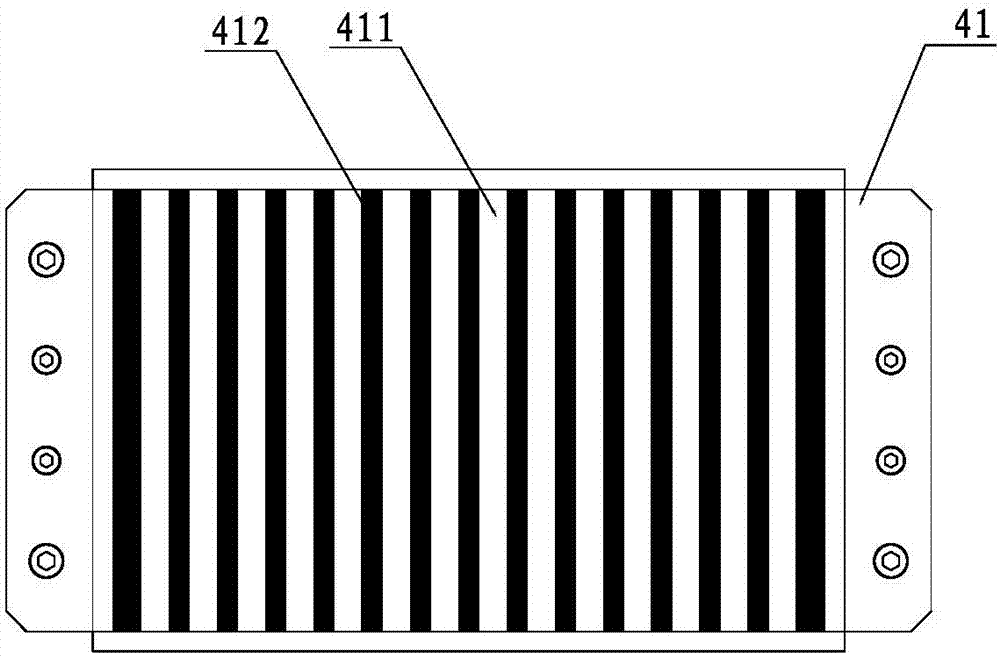

[0030] Such as Figure 1-2 As shown, a mobile 3D printer includes a base 1 , and an exposure mechanism 2 , a printing mechanism 3 , a liquid holding mechanism 4 and a control mechanism 5 arranged on the base 1 . In this embodiment, the base includes a base plate 11, an upper panel 12, and several columns 13 between the base plate 11 and the upper panel 12, wherein the exposure mechanism 2 and the control mechanism 5 are fixedly installed on the base plate 11 Above, the printing mechanism 3 and the liquid holding mechanism 4 are installed on the upper panel 12 . The exposure mechanism 2 is a projector, specifically a DLP projector can be used. The printing mechanism 3 includes a module 31 and a printing platform 32 slidably installed on the module 31. The printing platform 32 slides up and down through a leading screw vertically arranged in the module 31, and the printing platform 32 is connected with the leading screw. The lead screw is connected with the lead screw motor, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com