Test device for testing ship shafting performance under ice loads

A test device and load technology, which is applied in the direction of measuring device, fluid dynamics test, ship construction, etc., can solve the problems of lack of ice load action test items, blank dynamic characteristics, and inability to meet the requirements of the development of routes in the Arctic region, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

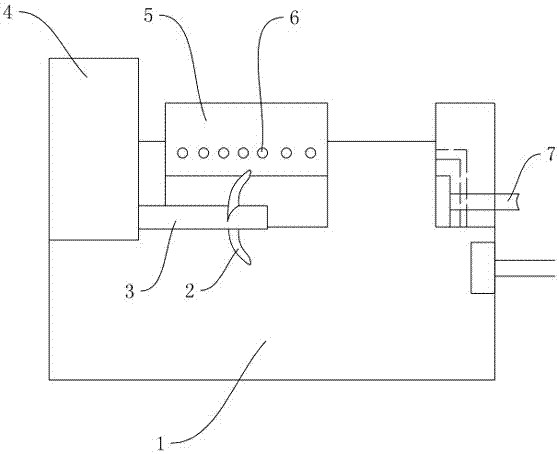

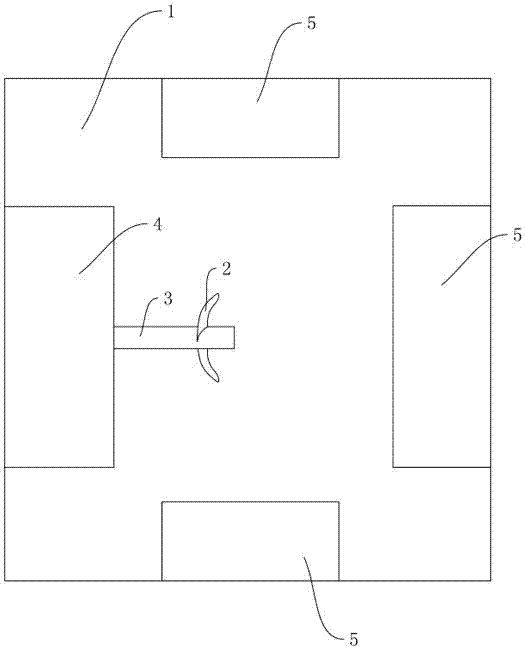

[0021] Embodiment: A kind of ship shafting performance test device under the action of ice load (see figure 1 figure 2 ), including: a water tank 1 for simulating the ocean and containing seawater, a test bench 4 for simulating the stern of a ship and partially submerged in the sea water of the water tank, set at the end of the test bench and extending into the sea water of the water tank for simulating the stern of the ship The rotating shaft 3 of the shaft, and the ice load generating device arranged around the rotating shaft. The tail end of the rotating shaft is fixed with a propeller. The size of the rotating shaft and the propeller is the same as the tail shaft used in the actual ship. The bearing is connected between the rotating shaft and the test bench, and the position of the axis of the tail shaft is equipped with a rubbing monitoring mechanism. The bottom of the water tank is provided with a rocking plate for generating seawater waves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com