Composite packaging material

A composite packaging material and packaging material technology, applied in the field of composite packaging materials for liquid beverage packaging, can solve problems such as affecting the reputation of manufacturers, market turmoil, and price confusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

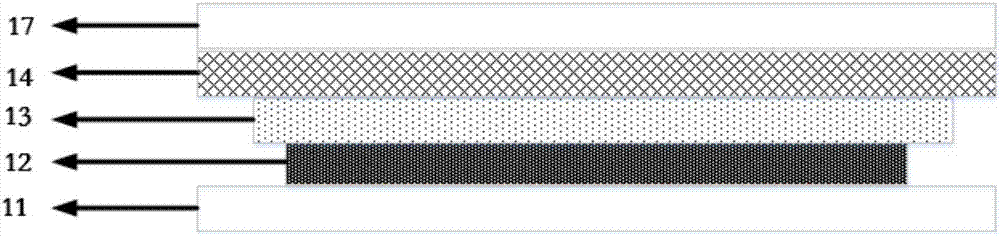

[0034] The technical means adopted by the present invention to achieve the intended invention purpose are further described below in conjunction with the drawings and preferred embodiments of the present invention.

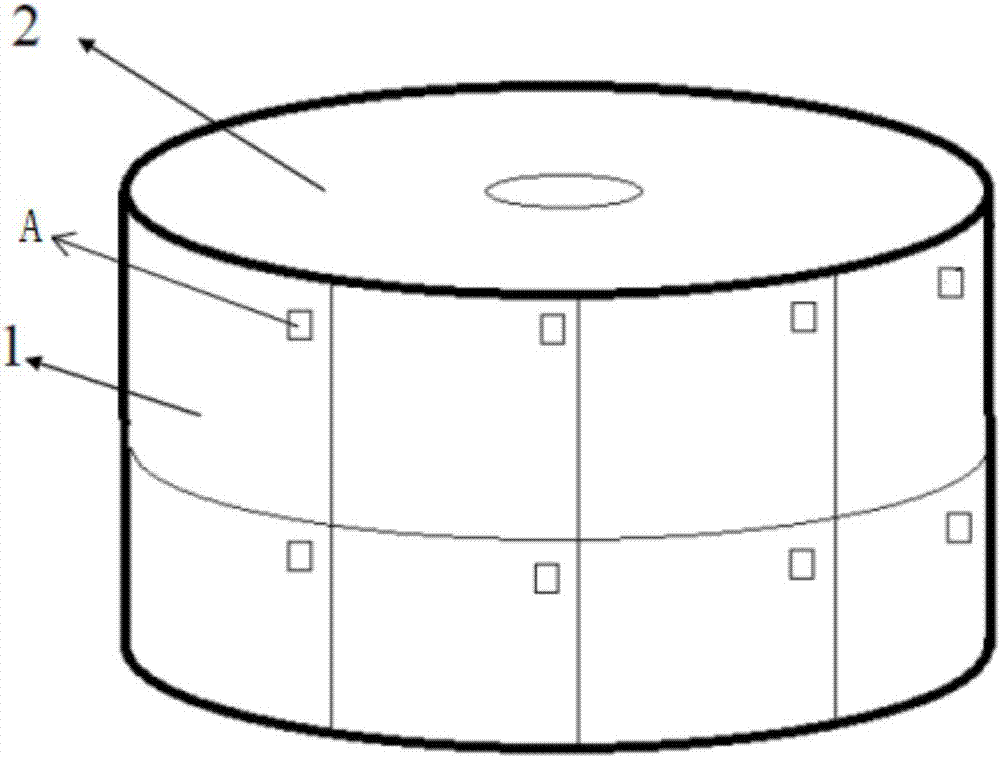

[0035] figure 1 Shown is a perspective view of a composite packaging material according to an embodiment of the present invention. The composite packaging material 2 has a plurality of units 1 for forming a single package. The area indicated by the letter A is the location of the first identification code 12 set on each unit, and the first identification codes 12 of any two units are different from each other. In addition, the relative position description from top to bottom in the layer structure description of the composite packaging material involved in the present invention corresponds to the relative position description from outside to inside when the composite packaging material is used for product packaging.

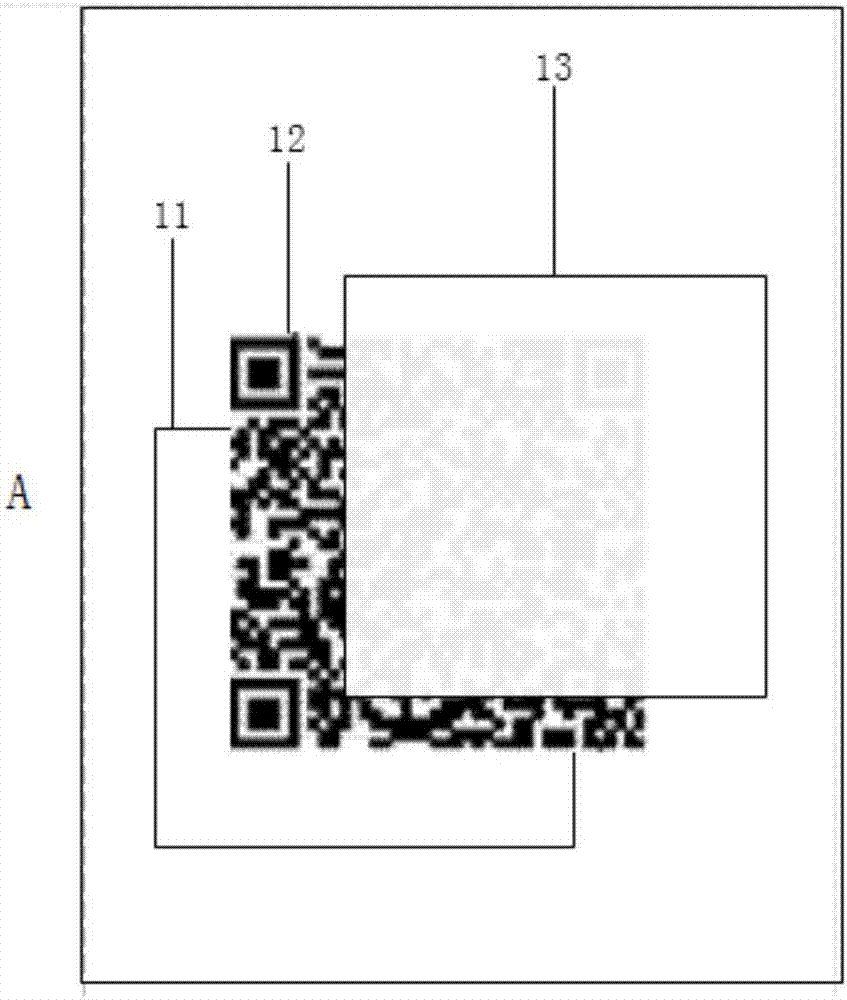

[0036] figure 2 Shown is a partial explode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com