Non-contact sleeper identification method in moving state

An identification method and sleeper technology, applied in the field of rail transit, can solve the problems of missing data detection, slow sensing speed, and inability to realize sleeper identification, and achieve the effects of preventing sleeper misdetection and improving accuracy and precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] refer to figure 1 , a non-contact sleeper recognition method in a moving state of the present invention, comprising the steps of:

[0023] (1) Fix the laser sensor on the bottom surface of the main beam of the dynamic measuring trolley, the emitting surface of the laser sensor is coplanar with the bottom surface of the main beam of the trolley, and the laser aiming line is aligned with the rail platform or sleepers;

[0024] (2) The dynamic measuring trolley moves along the measuring line at a constant speed, and the laser sensor scans the sleeper and ballast bed below it, measures the distance between it and the sleeper and ballast bed, and records the collected raw data;

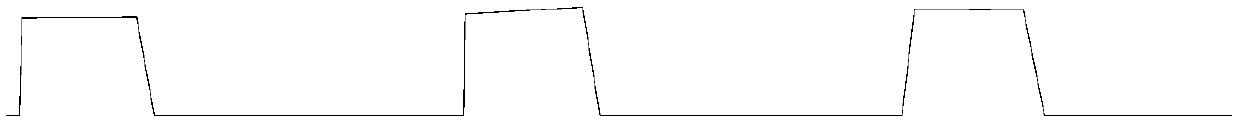

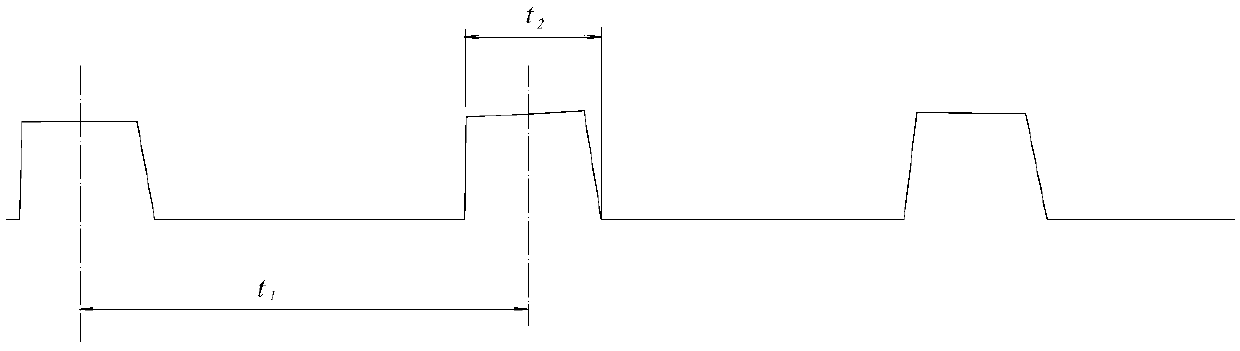

[0025] (3) Matching the laser sensor and the odometer to draw the original waveform diagram, the horizontal direction of the original waveform diagram is the mileage, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com