Lifting guide wheel group mechanism for cargo carrying platform of automatic three-dimensional warehouse

A technology of three-dimensional warehouse and guiding mechanism, which is applied in the field of warehousing and logistics, which can solve the problems of unfavorable space automatic adjustment, instability and hidden safety hazards, and achieve the effects of regular maintenance, improved logistics transportation efficiency, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

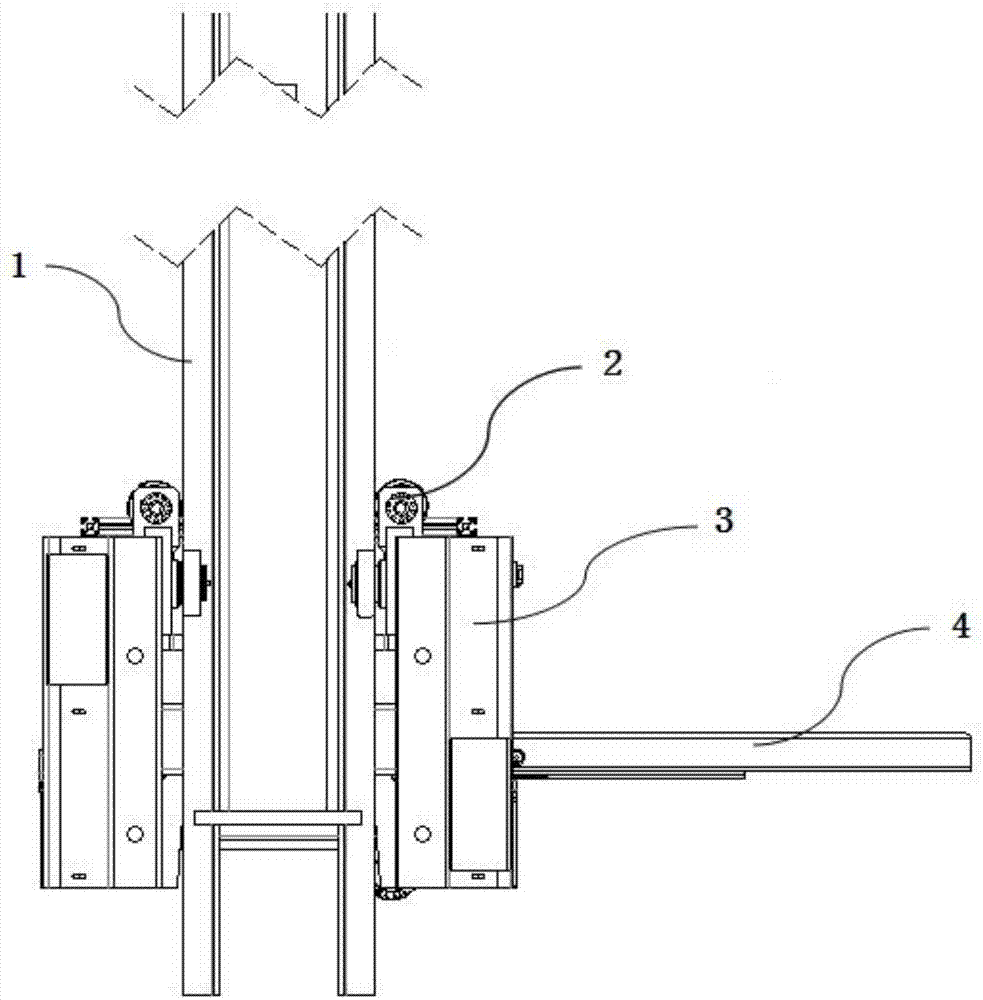

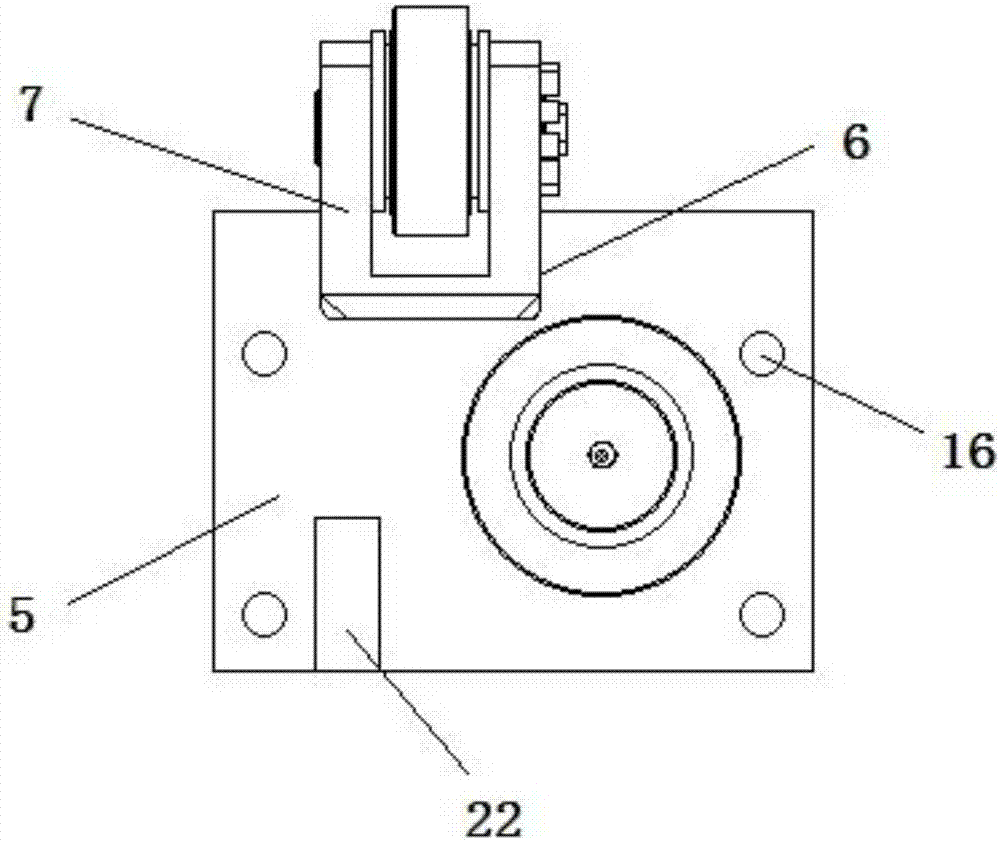

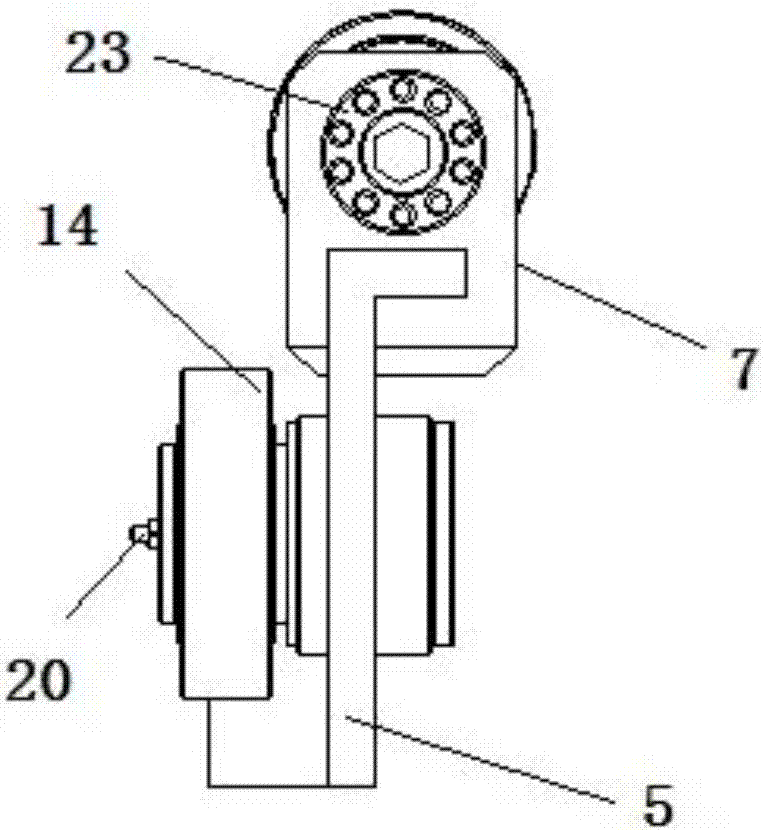

[0029] refer to Figure 1-7 A specific embodiment of the present invention includes a column guide rail 1, a guide mechanism 2 is slidably arranged on the column guide rail 1, a cargo platform 3 is fixed on the guide mechanism 2, a cargo fork 4 is arranged on the cargo platform 3, and the guide mechanism 2 includes a guide The wheel group support body 5, the top of the guide wheel group support body 5 is provided with a notch 6, and a U-shaped fork 7 is welded on the notch 6, and the U-shaped fork 7 is provided with a first eccentric shaft 8 through the first bushing 11, and the first shaft The sleeve 11 is provided with a first expansion sleeve 23, the first eccentric shaft 8 is provided with a first bearing 9, the two ends of the first bearing 9 are respectively provided with a first washer 10, and the guide wheel group support body 5 passes through the second shaft sleeve 12 is provided with a second eccentric shaft 13, the second eccentric shaft 13 is located between one e...

Embodiment 2

[0033] refer to Figure 8 (Because the first expansion sleeve 23 and the second expansion sleeve 24 have the same structure, this figure takes the first expansion sleeve as an example), this embodiment is improved on the basis of Embodiment 1. The first expansion sleeve 23 and the second expansion sleeve 24 are respectively provided with a cavity 25, the bottom of the cavity 25 is provided with a support plate 26, the outside of the support plate 26 is lower than the inner side of the support plate 26, and the top surface of the support plate 26 is provided with Several raised parts 27, elastic metal sheet 28 is arranged in the cavity 25, the top of elastic metal sheet 28 is connected with the top of cavity 25 through spring body 29, the outside of spring body 29 is provided with rubber damping sleeve 30, elastic metal sheet 28 The bottom is in contact with the raised portion 27 alternatively. When the bearing tends to jump or move, the corresponding expansion sleeve elastica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com