Method for evenly distributing water in shallow air flotation pool

A shallow air flotation and uniform water distribution technology, which is applied in the direction of water distribution pipes, flotation water/sewage treatment, etc., can solve problems such as disturbance, uneven water distribution, and different service area areas, so as to reduce radial flow and reduce The effect of inhomogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

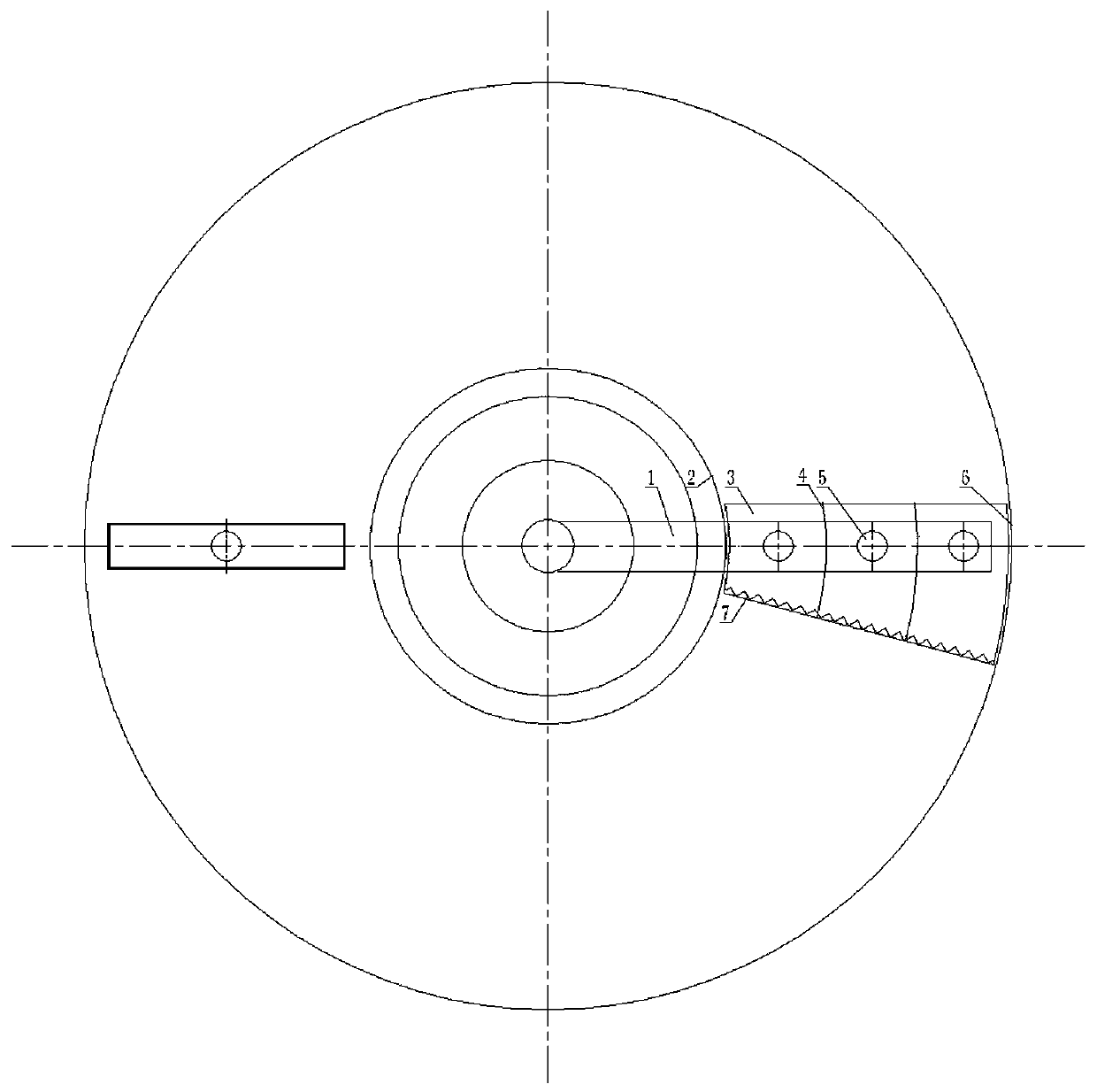

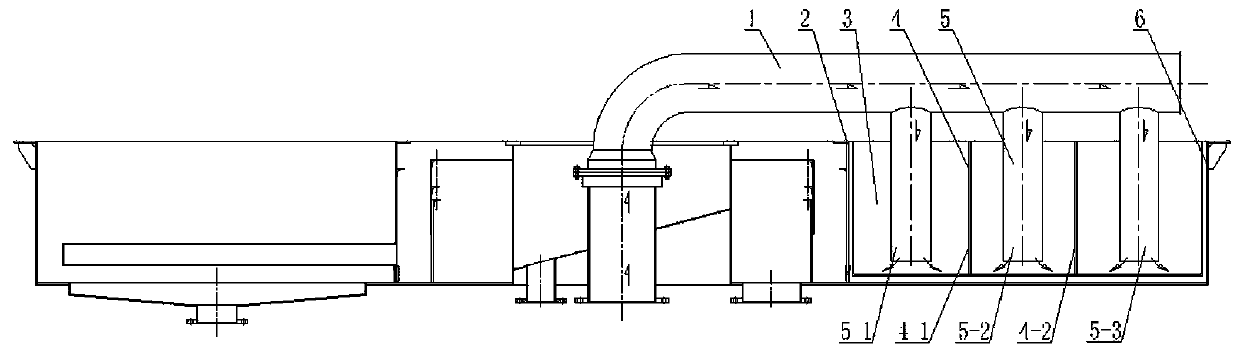

[0024] Such as figure 1 and figure 2 Shown in detail is the specific implementation of equal-diameter and unequal-distance distribution of water distribution pipes. The air flotation tank mainly includes: water distribution main pipe 1, separation bucket 2, water distribution tank 3, isolation plate 4, water distribution pipe 5, air flotation shell 6 and Steady flow grille7.

[0025] The diameter of the air flotation tank is 6.5m, and the treated water volume is 5000m 3 / d (i.e. 208m 3 / h). The diameter of the separation barrel is 2.5m, and the effective separation area is 28.26m 2 .

[0026] Raw water enters the water distribution tank 3 through the water distribution main pipe 1 through the water distribution pipe 5, and enters the flotation area enclosed by the air flotation shell 6 and the separation barrel 2 under the action of the isolation plate 4 and the steady flow grid 7, and performs zero-speed flotation , Solid-liquid separation.

[0027] The air flotation ...

Embodiment 2

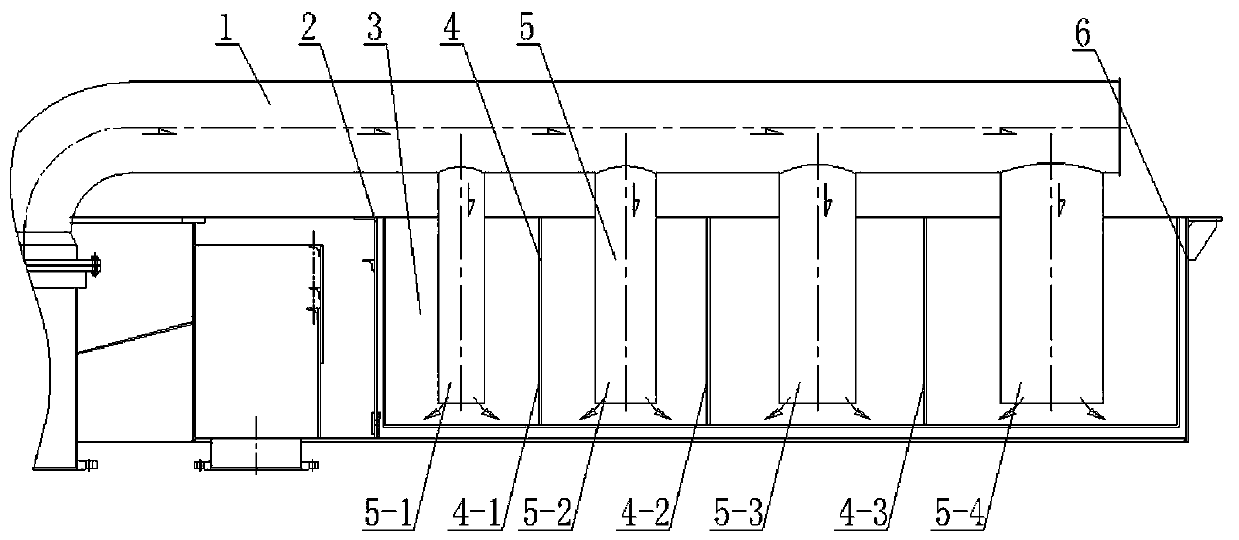

[0037] Such as image 3 The specific implementation of the unequal diameter and unequal distance water distribution of the water distribution pipe is shown in detail. In this embodiment, the diameter of the air flotation tank is 10m, and the treated water volume is 12500m 3 / d (ie 521m 3 / h). The diameter of the separation barrel is 2.6m, and the effective separation area is 73.19m 2 .

[0038] Raw water enters the water distribution tank 3 through the water distribution main pipe 1 through the water distribution pipe 5, and enters the flotation area enclosed by the air flotation shell 6 and the separation barrel 2 under the action of the isolation plate 4 and the steady flow grid 7, and performs zero-speed flotation , Solid-liquid separation.

[0039] Four water distribution pipes 5 are arranged radially in the air flotation tank, and the pipe diameters from inside to outside are as follows: the first water distribution pipe 5-1 is DN150, the second water distribution pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com