Method for purifying sewage

A sewage purification and sewage technology, applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of high cost of ultrafiltration membrane, cumbersome cleaning, ultrafiltration membrane pollution, etc., and achieve good results Economic benefits, large water outlet area, and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

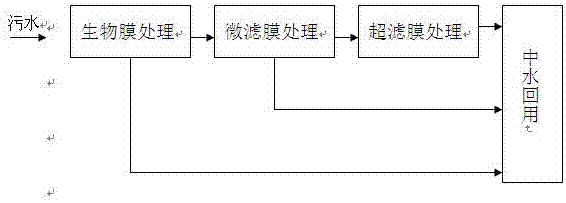

[0014] A method for purifying sewage. In the purification method, the sewage is sequentially passed through a multifunctional nitrification and denitrification integrated self-generated dynamic membrane bioreactor for the first biochemical treatment; through the microfiltration membrane for filtration and purification; through the ultrafiltration membrane for filtration Purification, the self-generating dynamic membrane bioreactor is a column structure, including a number of self-generating dynamic membrane module units, which are sequentially composed of a pretreatment reaction zone, an aeration reaction zone, and a semi-aeration reaction zone from bottom to top; each reaction zone separated by perforated plates.

[0015] The self-generated dynamic membrane bioreactor adopts the anoxic reflux type or the anoxic reaction of the fixed filler or the aerobic reaction of the suspended filler.

[0016] The self-generating dynamic membrane module unit is composed of a PVC support fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com