A Constraint-Guided Rail Vibration Damping Fastener Structure

A vibration-absorbing fastener and guide-type technology, applied in the direction of tracks, roads, fixed rails, etc., can solve the problems of interchangeability, poor versatility, large overall height of fasteners, difficulty in disassembling fasteners, etc., and achieve strong versatility , Efficient vibration reduction effect, convenient and quick removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

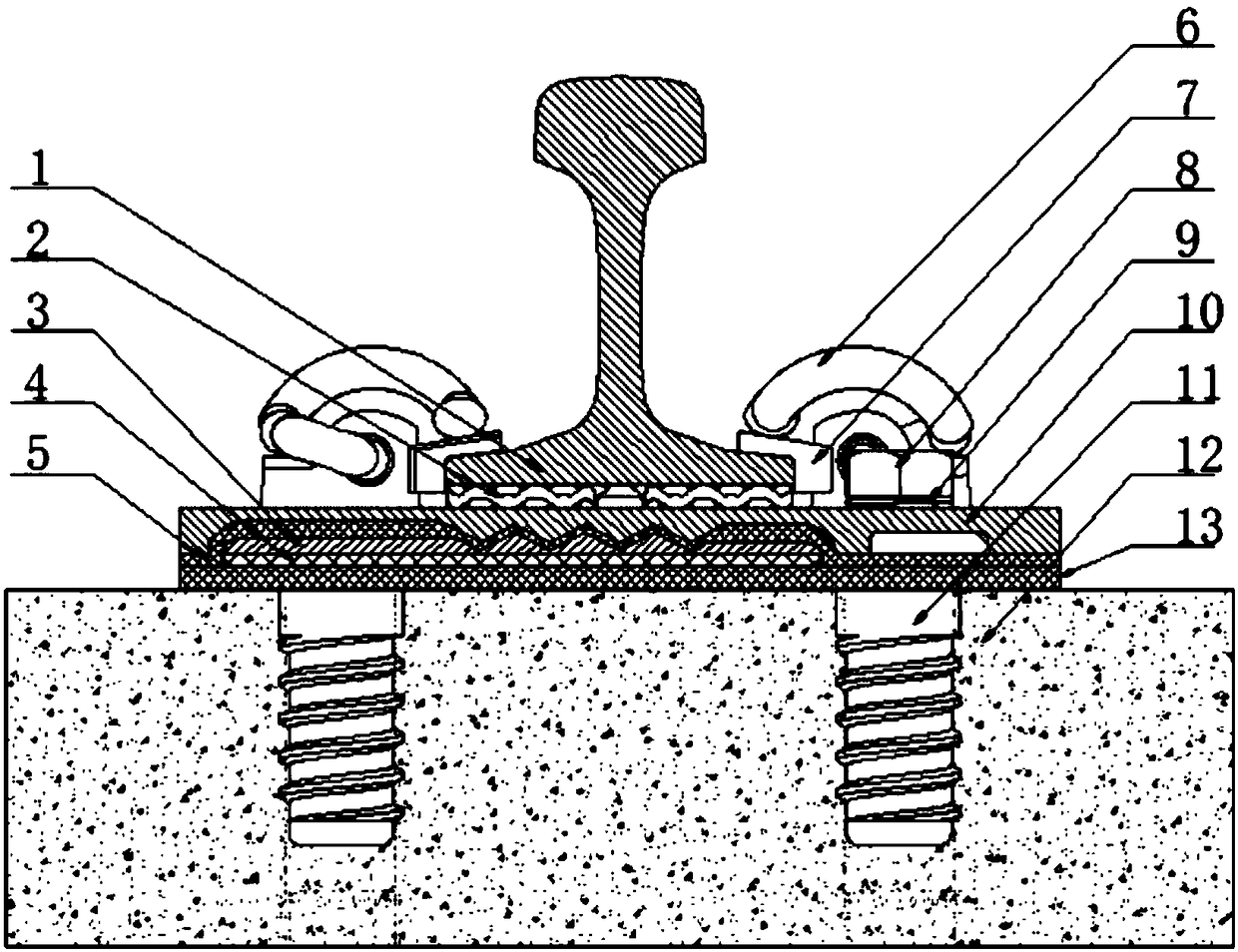

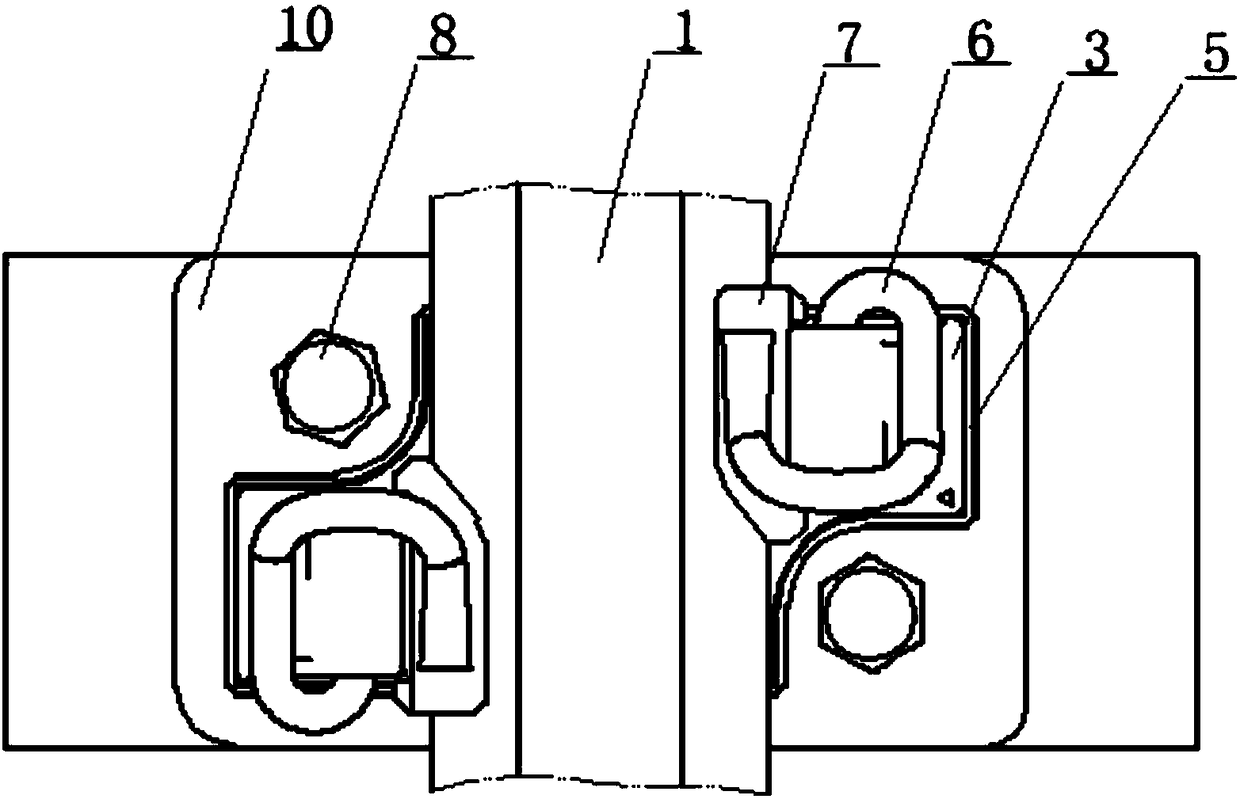

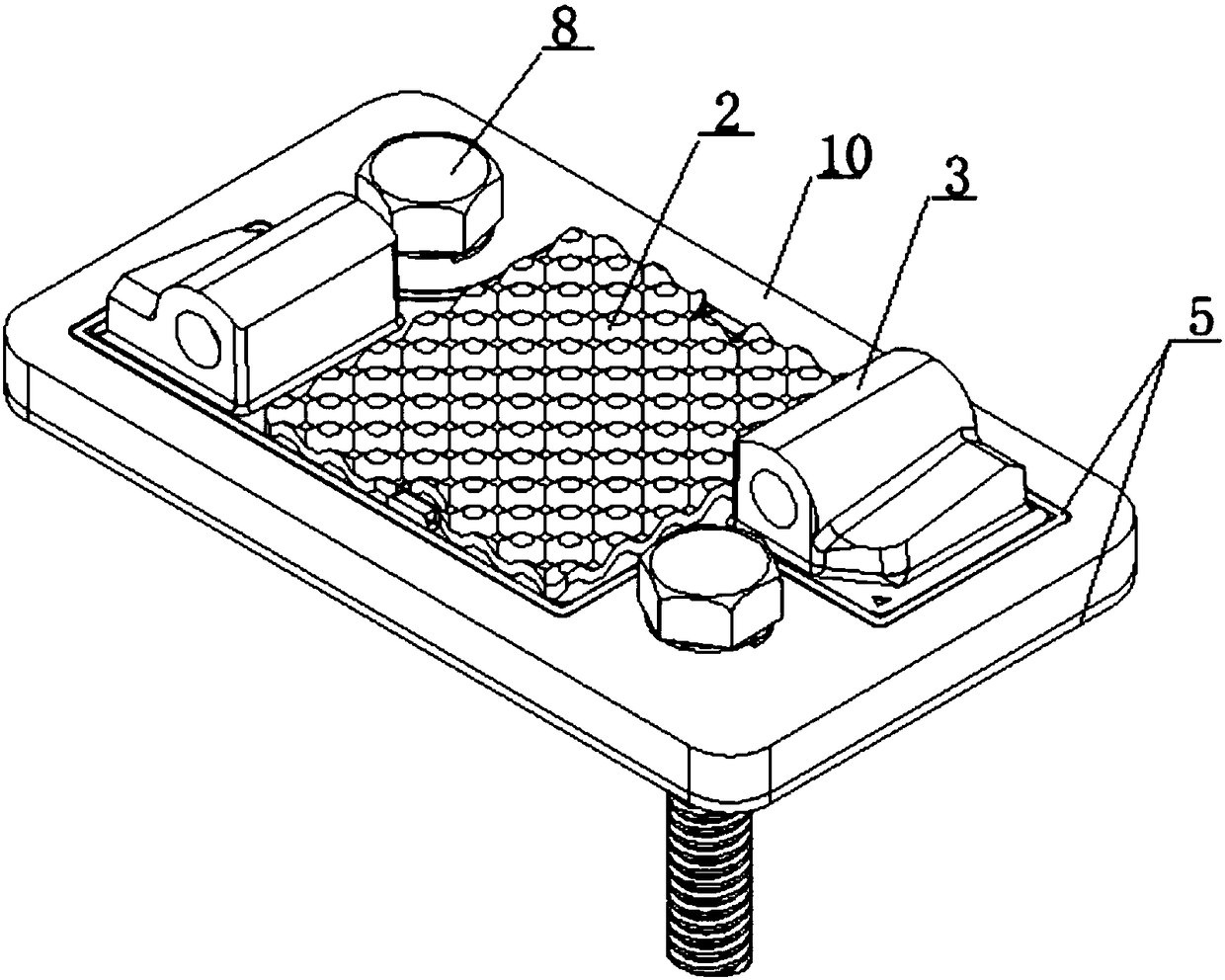

[0025] The following is attached Figure 1-7 An embodiment of the present invention is described.

[0026] A restraint-guided rail vibration-damping fastener structure, comprising an under-rail elastic backing plate 2, a rail-supporting iron backing plate 3, an under-board elastic backing plate 4, a constraint insulating sleeve 5, an elastic bar 6, a gauge pad 7, and a spiral track Nails 8, washers 9, outer frame constraint iron backing plate 10, embedded casing 11 and height adjustment backing plate 13; the height adjustment backing plate 13 is laid on the sleeper, and the elastic backing plate 4 under the board is laid on the height adjustment Backing plate 13. The upper surface of the elastic backing plate 4 under the plate has a positioning boss 17, and the lower surface of the rail iron backing plate 3 has a positioning groove 18 matching the positioning boss 17, and the positioning groove 18 is clamped on the On the positioning boss 17, and then the iron backing plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com