Control module for actuating clutch in hydraulic controlling manner

A technology for operating modules and clutches, applied in clutches, components with teeth, transmission control, etc., can solve the problems of huge consumption and space requirements, and achieve the effects of saving space, prolonging service life, and high integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

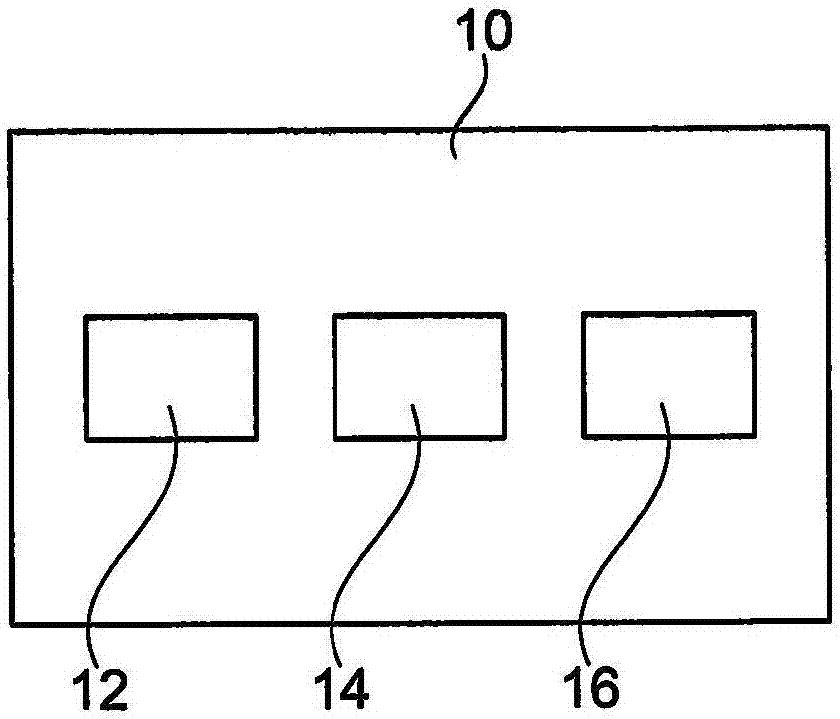

[0036] figure 1 A schematic illustration of a first embodiment of an actuation module 10 for hydraulically actuating clutch actuation or gear actuation in a clutch transmission, in particular a dual clutch transmission, is shown in . The schematic diagram shows all components as rectangles. Furthermore, the connections to one another and to the clutches are not shown. The schematic diagram should only indicate which components are used in the operating module 10 . The manipulation module 10 comprises: a reversible pump 12 for conveying a working fluid, wherein the reversible pump 12 has a first conveying direction and a conveying direction opposite to the first conveying direction; type driving device 14; and a local controller 16 for controlling the driving device 14. The reversible pump 12 , drive 14 and controller 16 together form an electric pump actuator (abbreviated EPA).

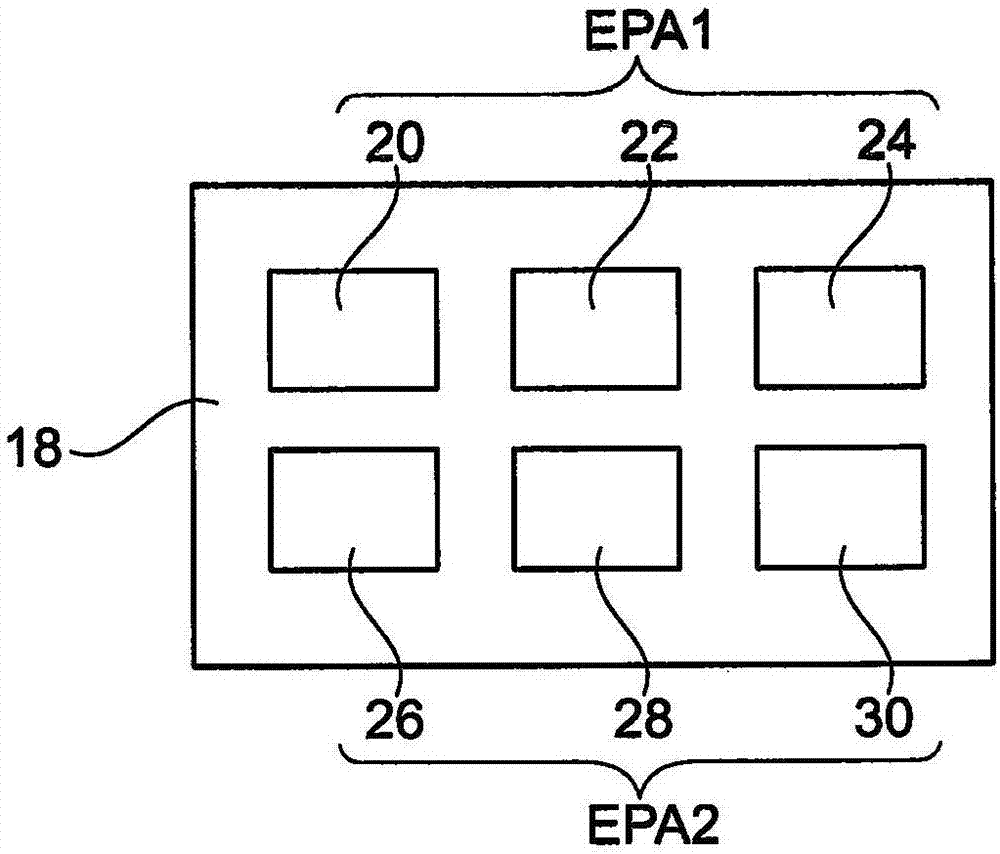

[0037] figure 2 A schematic diagram of a second embodiment of the actuation module 18 is sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com